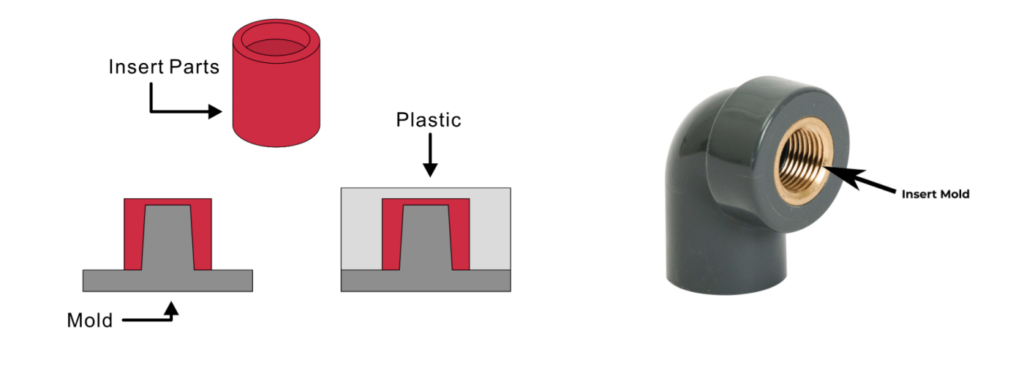

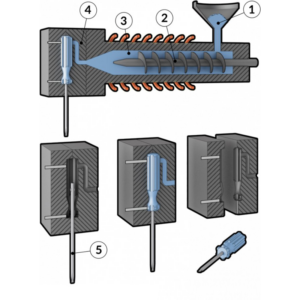

Our plastic insert molding molds are expertly crafted to address complex manufacturing challenges, delivering enhanced strength and durability by seamlessly integrating components. We offer tailored solutions with advanced techniques like multi-material molding and precise insert placement, ensuring a flawless bond and superior performance. Each mold is designed with meticulous precision and optimized for long-term durability. With our expertise, we ensure efficient, reliable production and cost-effective solutions that are customized to meet your exact needs.

Basic Information

Place of Origin: Xiamen, China

Brand Name: OEM

Product Material: Metal

Material: Stainless Steel

Runner: Hot Runner / Cold Runner

Cavity: Single Cavity / Multiple Cavity

Surface Treatment: Polishing / Texture

Color: Customized Colors

Service: Customized OEM CNC Machining

Delivery Time: 20-25 Days

Quality: 100% Inspection

Drawing Format: 3D, STP, STEP, IGS, PRT, X_T

Advantages of our product

- High Dimensional Accuracy: Our molds are designed and manufactured with precise engineering to ensure exact replication of product specifications, reducing the risk of defects and minimizing the need for post-production adjustments.

- Enhanced Durability: Constructed from high-quality steel and treated with advanced surface finishes, our molds are engineered to withstand high-pressure conditions and extensive use, extending their service life and reliability.

- Superior Surface Quality: We offer a range of surface treatments, including polishing and texturing, to achieve optimal finish and functionality. This ensures that the final products exhibit excellent surface quality and consistency.

- Efficient Heat Distribution: Our molds are designed with effective cooling and heating systems, such as optimized runner layouts and temperature control, to enhance production efficiency and maintain uniformity in the final product.

- Versatile Application: Our molds support a wide range of plastic materials and processes, including complex geometries and intricate designs, making them suitable for various industries and applications.