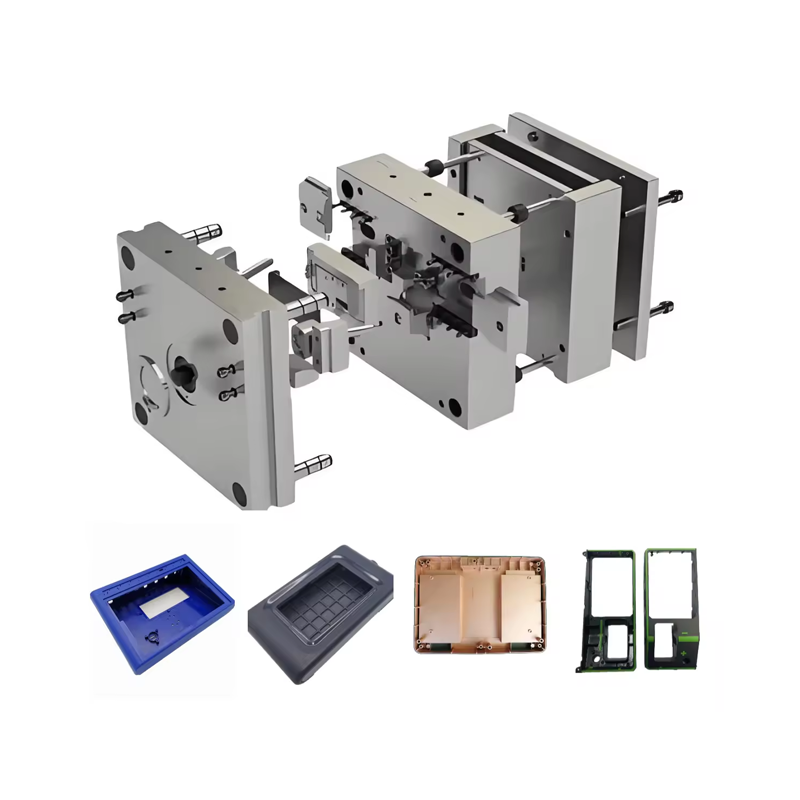

Plastic Injection Molding Mold for Custom Plastic Product Parts

Characteristics:

| Feature | Details |

| Material | Silicone/Rubber |

| Shape | Customizable |

| Color | Custom colors (Pantone matching) |

| Hardness | Shore 30-90 or as specified |

| Minimum Order | Small orders accepted |

| Lead Time | 3-6 weeks after mold design confirmation |

| Drawing Format | .stp, .step, .igs, .stl, .dwg, .pdf |

| Surface Treatment | Matte, Common polishing, Mirror polishing, Texture, Laser Engraving, Power Coating (Painting), Printing, Segmented colors, Mixed colors, etc. |

| Application | Automotive, Machinery, Bathroom Facilities, Medical, Household Electrical Appliances |

| Performance | High/low temperature resistance, wear resistance, high tensile strength |

| Mould Material | No. 50 steel, No. 45 steel, P20, 8407, H13, 718H, etc. |

| Mould Life | 100,000 – 500,000 shots |

| Mould Testing | All molds tested before shipment; videos of trial runs available |

| Inspection | 100% QC and QA inspection before shipping |

| After Sales Service | Available from staff with over 10 years of experience in the field |

Production Process of Plastic Injection Molding Mold:

- Design and Engineering:

– Begin with detailed design and engineering using CAD software. Create 2D and 3D models of the mold and parts to ensure precise specifications and functionality.

- Material Selection:

– Choose appropriate materials for both the mold and the plastic to be injected. Common mold materials include steel and aluminum, while plastic types vary depending on the application.

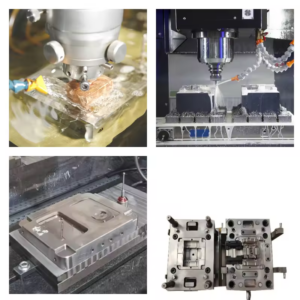

- Mold Fabrication:

– Machine the mold base and core using CNC machining, EDM (Electrical Discharge Machining), and other precision manufacturing techniques to achieve exact dimensions and tolerances.

- Heat Treatment:

– Subject the mold components to heat treatment processes to enhance durability and wear resistance.

- Assembly:

– Assemble the mold components, including the core, cavity, ejector system, and cooling channels, ensuring all parts fit together seamlessly.

- Polishing and Surface Finishing:

– Polish and finish the mold surfaces to achieve the desired texture and smoothness, critical for the final product’s surface quality.

- Trial Runs and Testing:

– Conduct trial runs to test the mold and make necessary adjustments. This step ensures that the mold produces parts that meet design specifications and quality standards.

- Quality Control:

– Perform rigorous quality control inspections, including dimensional checks, functional testing, and durability assessments, to ensure the mold’s performance.

- Production:

– Once approved, use the mold in injection molding machines to produce the final plastic parts. Monitor the process closely to maintain consistent quality and efficiency.

- Maintenance:

– Regularly maintain the mold to extend its lifespan and ensure continued high-quality production. This includes cleaning, lubrication, and periodic inspections for wear and tear.

OEM/ODM Services for Plastic Injection Molding Mold:

Custom Design and Engineering

– Custom Design: Tailored 3D models and technical drawings using advanced CAD software.

– Engineering Consultation: Expert support for optimal design, manufacturability, and cost-efficiency.

Precision Mold Fabrication

– Mold Design: High-precision molds based on finalized designs.

– Mold Manufacturing: State-of-the-art CNC machining for quality and durability.

High-Quality Material Selection

– Material Expertise: Selection of the best materials for performance and cost-effectiveness.

Advanced Injection Molding

– Injection Molding: Advanced techniques ensuring tight tolerances and high repeatability.

– Production Scalability: Flexible production for small to large volume orders.

Stringent Quality Control

– Inspection and Testing: Rigorous quality checks to meet specifications.

– Continuous Improvement: Methodologies to enhance quality and efficiency.

Post-Production Services

– Assembly and Finishing: Additional services for ready-to-use products.

– Custom Packaging: Packaging solutions to protect and brand your parts.

Comprehensive After-Sales Support

– Technical Support: Ongoing maintenance and support.

– Customer Service: Prompt and effective responses to queries and concerns.