Custom Mold Display

Here are molds spanning various industries, each meticulously designed and manufactured with rigorous processes. Additionally, we offer comprehensive customization services, ensuring that no matter your industry, we can tailor a mold to meet your specific needs.

Details: – Place of Origin:Xiamen, China – Service:OEM – Product Material:Steel – Shaping Mode:Plastic Injection Mould – Injection Material:ABS, PP, PS, PE, PVC, PA6, PA66, etc. – Mould Material:P20, 718, 738, NAK80, S136, 2738, 2316 – Mold Base:LKM, HASCO, DME, or Chinese Standard – Tolerance:0.003mm – 0.01mm – Drawing Format:STEP, STP, IGS, X-T, STL, CAD, […]

Design and Prototype Development The mould creation process begins with a comprehensive design phase, where the specific shape, dimensions, and intricate details of the intended part are meticulously planned. After the design is finalized, a prototype is developed to serve as a preliminary model. This prototype is essential for validating the mould’s ability to produce […]

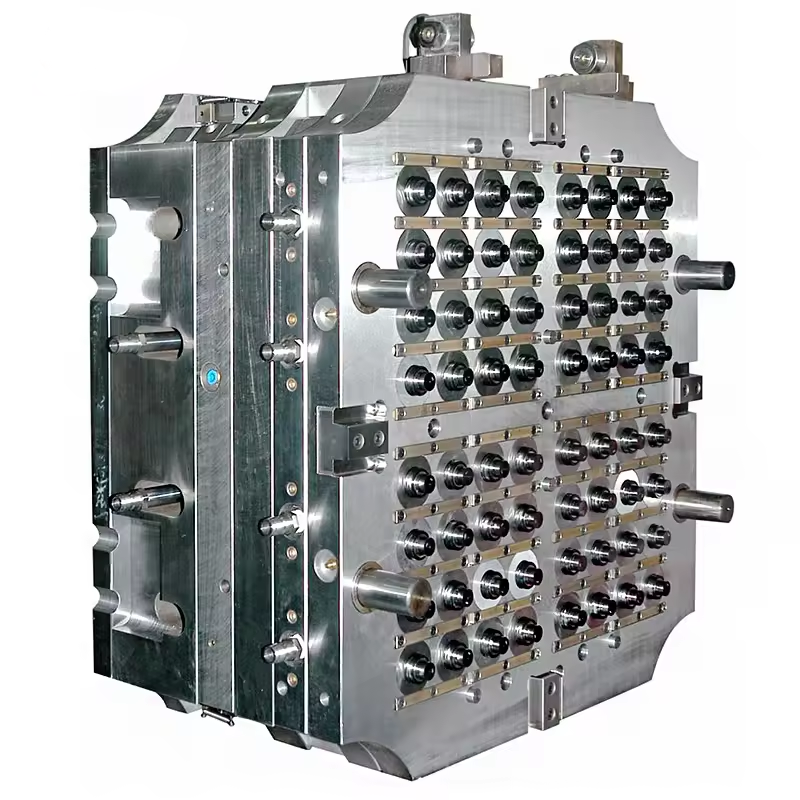

Custom Plastic Injection Molding provides an excellent method for creating specialized plastic components. For clients seeking large-scale production or sets of related parts, using family molds or multi-cavity molds can lead to considerable savings in both time and cost. Family mold and multi-cavity injection molding are both effective techniques for producing multiple parts at once. […]

Precision Plastic Moulding Expertise With extensive experience in producing a wide range of precision plastic mouldings, we specialize in several key areas: – Insert & Outsert Mouldings: Expertise in manufacturing components such as plugs, moulded terminals, thumb nuts, and electrical connectors. – Intricate & Micro Precision Mouldings: Proficiency in creating highly detailed and extremely small […]

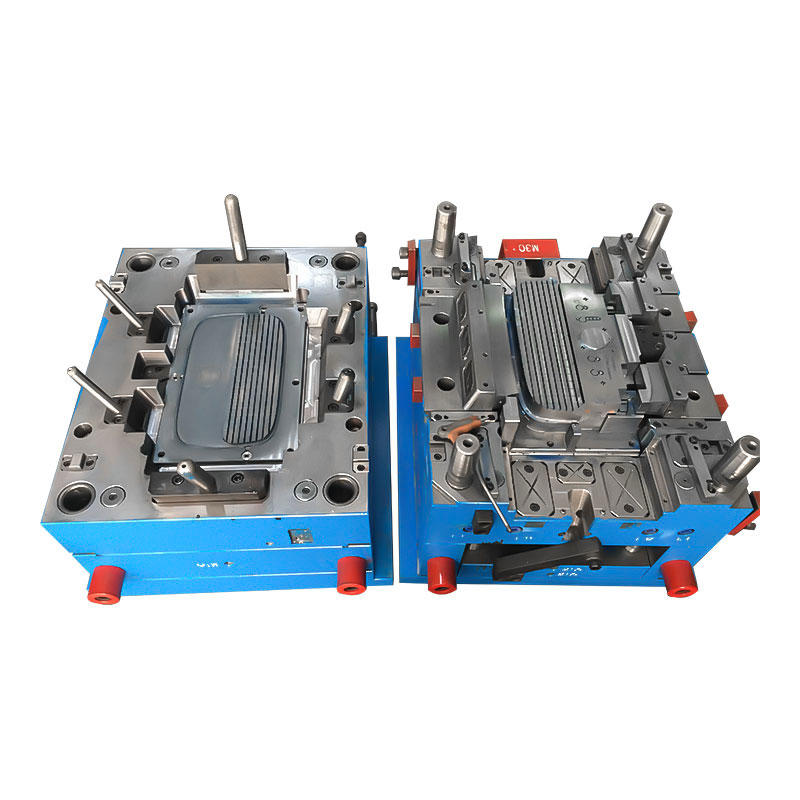

The Household Appliance Housing Mold is a specialized tool designed for the production of durable and precisely engineered plastic housings for various household appliances. Crafted from high-quality materials, this mold ensures consistent and accurate manufacturing of complex shapes and intricate details, meeting the exact specifications required for modern appliances.With a focus on longevity and efficiency, […]

Production Details Product name Medical Disposable Testing Tube 2K Injection Mold Core Mold shaping Plastic Injection molding, Mold base LKM;HASCO;DME,etc Mold material NAK20,S136,P20.718H,738H,45#,etc Mold cavity Single or Multi Tolerance +/-0.001mm Finish Anodized,Polish,Silk-screen,Painting,etc Sprue gate Hot/cold runner;pin-point gate,etc Design software UG,PROE,CAD,SOLIDWORK,etc Product material ABS,PP,PE,POM,PMMA,etc Mold life 100k-500k shots Lead time 25-45 days Transportation By sea, by air or by land as you request Package Standard or as you request OEM/ODM Acceptable Certificate ISO9001:2015,SGS,TS16949 Our Competitive Edge: – Premium Quality Standards – Competitive Pricing Structure – Timely Delivery […]

OEM Services for Molds – Custom Design: Develop bespoke designs based on client specifications, including detailed technical drawings and 3D models. – Material Selection: Assist clients in choosing the right materials for both the mold and the end product to ensure durability and performance. – Tooling Development: Design and manufacture custom tooling and molds tailored […]

Overview: Injection plastic mop bucket molds are designed to utilize advanced plastic injection technology for producing high-quality mop buckets. Our molds are engineered to create a flawless bucket body with smooth, seamless edges and an aesthetically pleasing dripping grid. This design ensures both functionality and visual appeal. Additionally, our molds are crafted to prevent mop […]

Overview: Creating a high-quality kitchen sink is crucial, and its production process is inherently complex. Fortunately, our factory simplifies this process through extensive experience and expertise. With many years in sink manufacturing, our skilled technicians ensure rigorous quality control throughout production, even when dealing with large-scale molding projects. Our molds are designed to be as […]

Design and Prototype Development The initial phase of mould creation involves designing the mould. This design specifies the shape, size, and intricate details of the part to be produced. After finalizing the design, a prototype is developed. The prototype serves as a test model to ensure the mould can produce the intended part accurately. Once […]

.png)