Custom Mold Display

Here are molds spanning various industries, each meticulously designed and manufactured with rigorous processes. Additionally, we offer comprehensive customization services, ensuring that no matter your industry, we can tailor a mold to meet your specific needs.

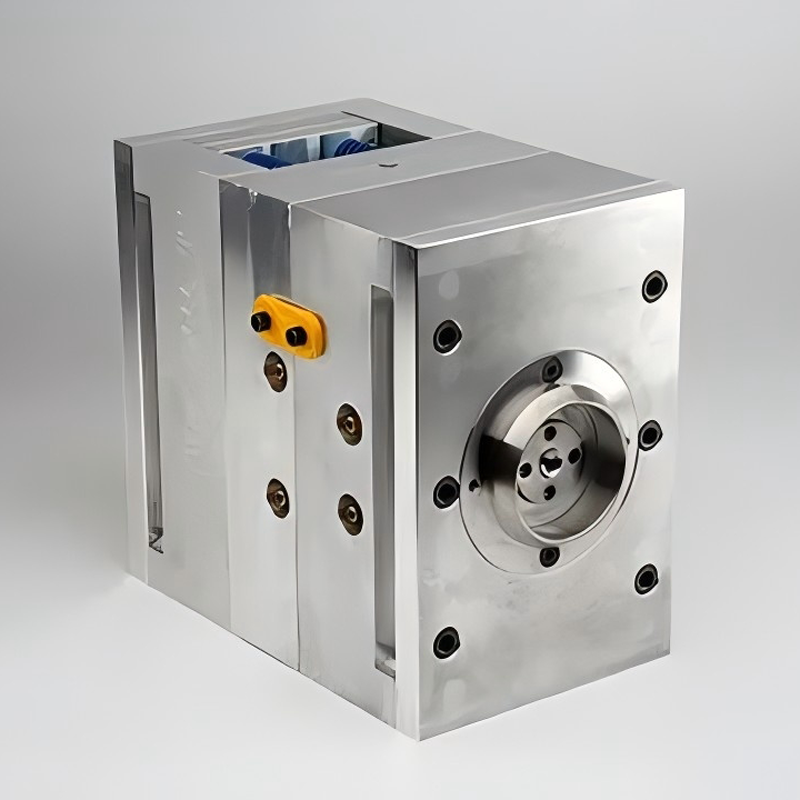

Our Matte Plastic LSR Overmolding Mold provides an innovative solution for producing durable silicone components with a matte finish. Engineered for precision, this mold integrates the strength of liquid silicone rubber (LSR) with a sleek, non-slip surface that reduces glare. Combining aesthetics and functionality, it is ideal for high-performance applications. Through advanced LSR injection molding […]

Our plastic injection molding polishing molds are expertly crafted to produce smooth, premium surfaces that enhance both aesthetics and functionality. By employing cutting-edge polishing methods—mechanical, chemical, and electrolytic—we achieve precise, mirror-like finishes that minimize friction and optimize part release. We offer tailored solutions to meet your exact specifications, covering dimensions, surface treatments, and material choices. […]

Our plastic insert molding molds are expertly crafted to address complex manufacturing challenges, delivering enhanced strength and durability by seamlessly integrating components. We offer tailored solutions with advanced techniques like multi-material molding and precise insert placement, ensuring a flawless bond and superior performance. Each mold is designed with meticulous precision and optimized for long-term durability. […]

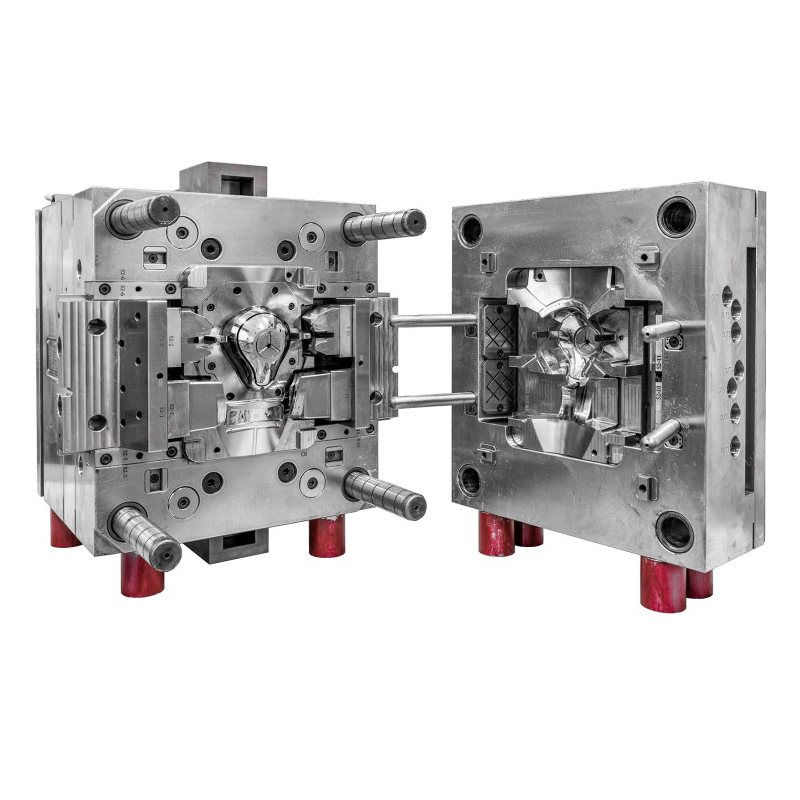

Our expertly engineered 2-shot plastic molding molds are designed to deliver unparalleled quality and precision in multi-material molding processes. Also referred to as dual-shot, double-shot, or multi-shot molding, this technique combines two distinct plastic resins in a single production cycle, significantly enhancing efficiency and ensuring product integrity. This cutting-edge molding process is ideal for producing […]

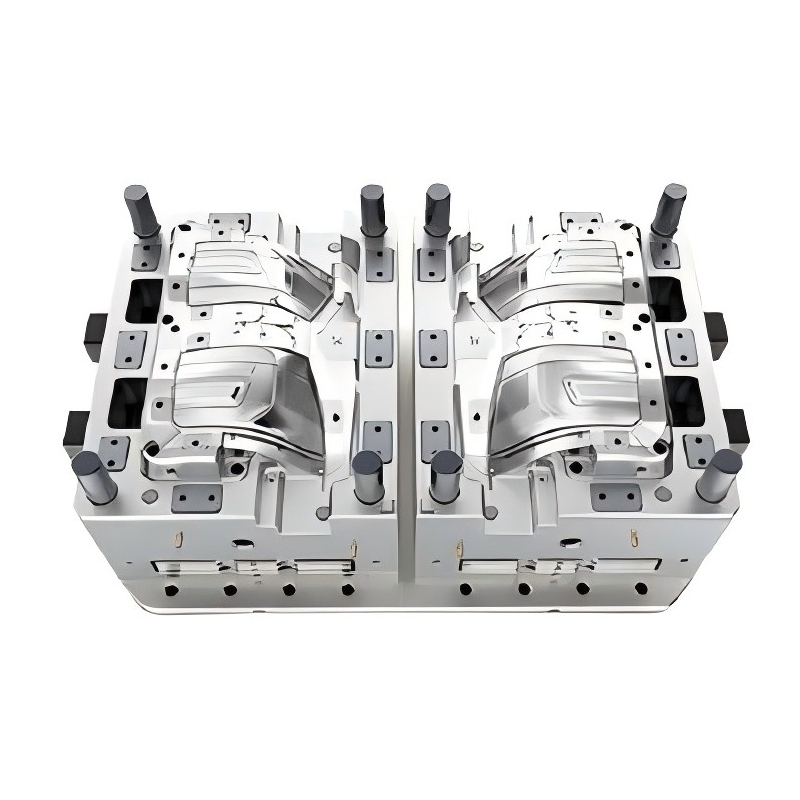

Our precision-engineered plastic injection molding molds are designed to meet the specific requirements of each client. With advanced technical expertise, we produce molds that deliver superior performance, durability, and versatility across a wide range of industries. We are dedicated to offering customized solutions, ensuring every mold is manufactured with the highest level of precision and […]

Our plastic overmolding tooling solutions are meticulously designed for precision in multi-material and multi-component applications, ensuring seamless bonding between materials such as thermoplastics and elastomers. Leveraging cutting-edge CNC machining, EDM technology, and specialized surface treatments, we produce tooling that guarantees superior durability and consistent performance. Every tool is subjected to thorough quality checks at each […]

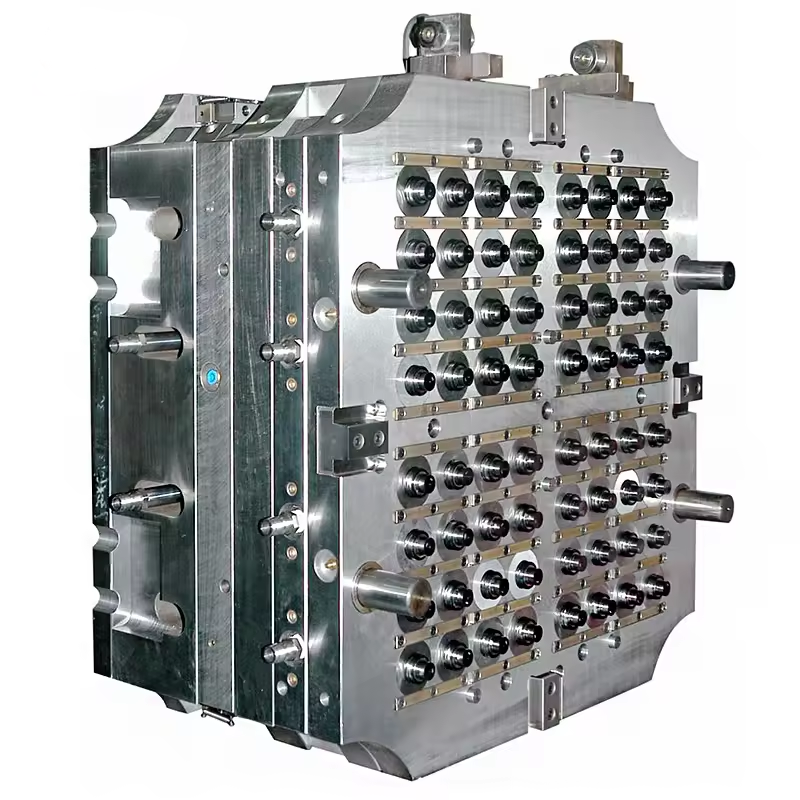

Our expert craftsmen utilize high-speed mills to ensure the precise dimensional accuracy essential for Thermoset molding. With over 20 years of experience in Thermoset tooling, we consistently deliver flash-free tools that are production-ready. Our team possesses deep expertise in selecting specialty steel, determining optimal heater and sensor placement, and applying suitable coatings to enhance tool […]

Customization and Capacity The number of cavities in a mould can be customized based on the customer’s production requirements, ensuring optimal production capacity and efficiency. We provide high-quality moulds tailored to meet the specific needs of our clients, ensuring consistent and reliable performance in the manufacturing of automotive parts. Our expertise in manufacturing high-precision moulds […]

Mold Manufacturing Process Product and Mold Design: Initial design phase where the product and mold are conceptualized and planned. Packaging: Preparation and packaging of components for the manufacturing process. Steel Preparation: Selection and preparation of steel for mold creation. Mold Testing: Conducting trials to ensure mold functionality and accuracy. Deep Hole Drilling: Precision drilling to […]

Details: – Place of Origin:Xiamen, China – Service:OEM – Product Material:Steel – Shaping Mode:Plastic Injection Mould – Injection Material:ABS, PP, PS, PE, PVC, PA6, PA66, etc. – Mould Material:P20, 718, 738, NAK80, S136, 2738, 2316 – Mold Base:LKM, HASCO, DME, or Chinese Standard – Tolerance:0.003mm – 0.01mm – Drawing Format:STEP, STP, IGS, X-T, STL, CAD, […]