Custom Mold Display

Here are molds spanning various industries, each meticulously designed and manufactured with rigorous processes. Additionally, we offer comprehensive customization services, ensuring that no matter your industry, we can tailor a mold to meet your specific needs.

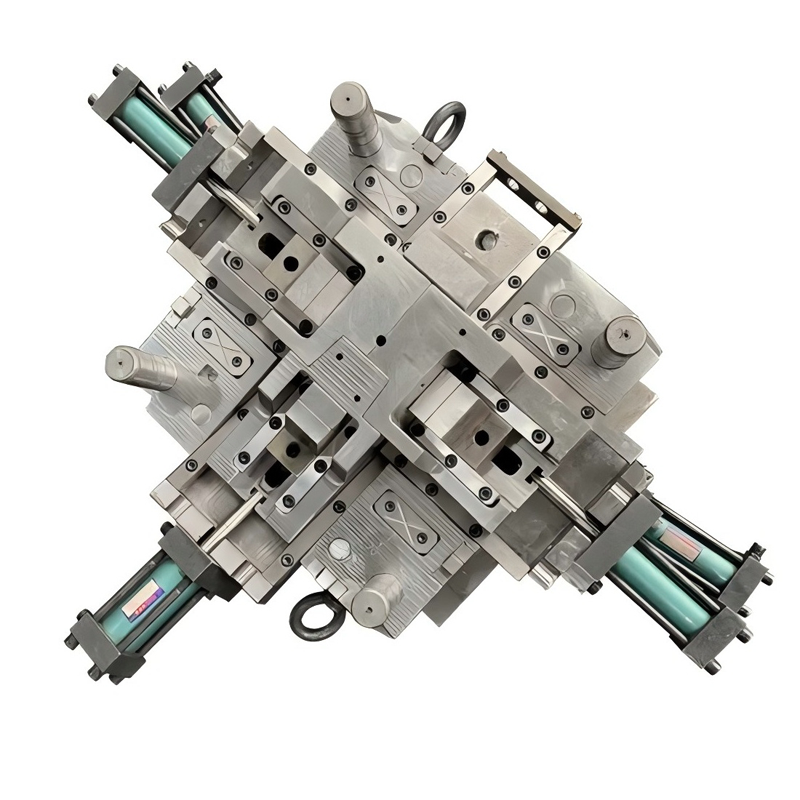

Our plastic injection molding molds for instruments and apparatus are engineered with precision and tailored to meet each client’s specific requirements. Utilizing cutting-edge injection molding technology, we produce highly accurate and durable molds that guarantee top performance for your devices. Specializing in custom mold design and manufacturing, we offer rapid prototyping to refine and perfect […]

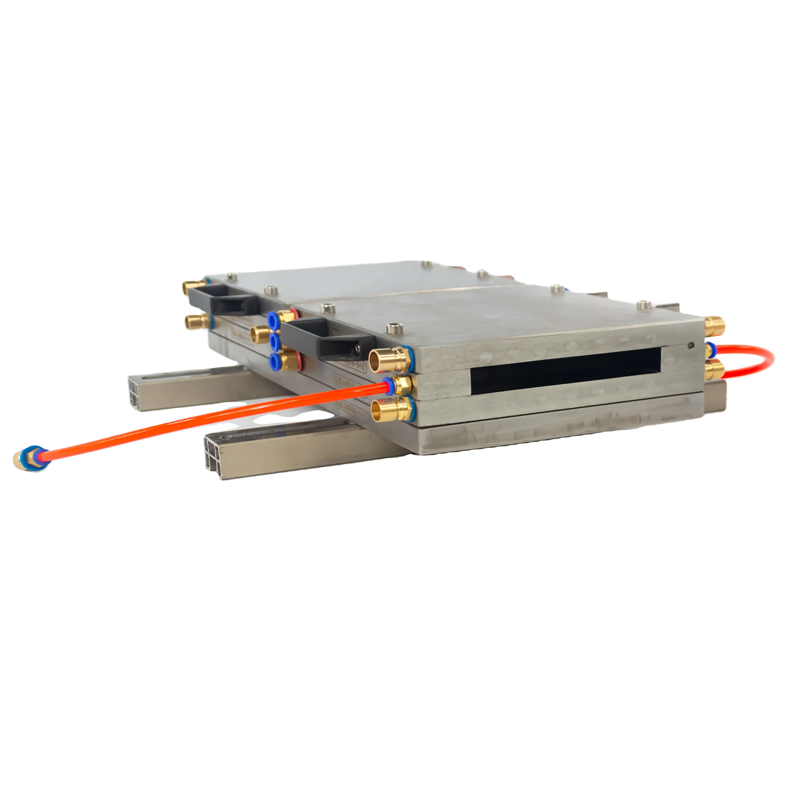

Our cutting-edge plastic insert molding solutions for new energy applications. Our advanced molds are designed to deliver exceptional quality, meeting stringent customization requirements and enabling high-volume production with rapid prototyping capabilities. The precision-engineered molds are perfect for producing durable, reliable components essential for the latest new energy systems. With a focus on high performance and […]

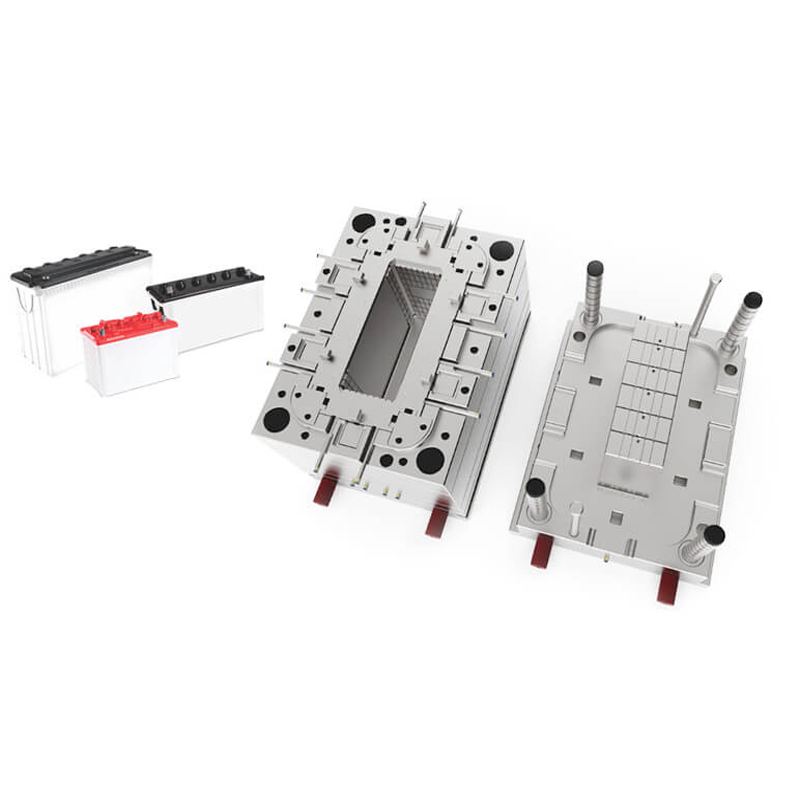

Our innovative plastic insert molding solutions for battery equipment and new energy applications are engineered for precision and reliability. Designed to meet strict customization demands, our advanced molds facilitate high-volume production while offering rapid prototyping capabilities. Ideal for creating durable, high-performance components for cutting-edge battery technologies , these molds ensure efficient, scalable manufacturing. Whether you […]

Product Overview: Our extrusion molds for household products are precision-engineered tools crafted from high-grade steel, ensuring durability and longevity. Designed for creating a variety of plastic items through an advanced extrusion process, these molds allow heated plastic to be forced through a die to form continuous shapes, perfect for products like tubing and profiles used […]

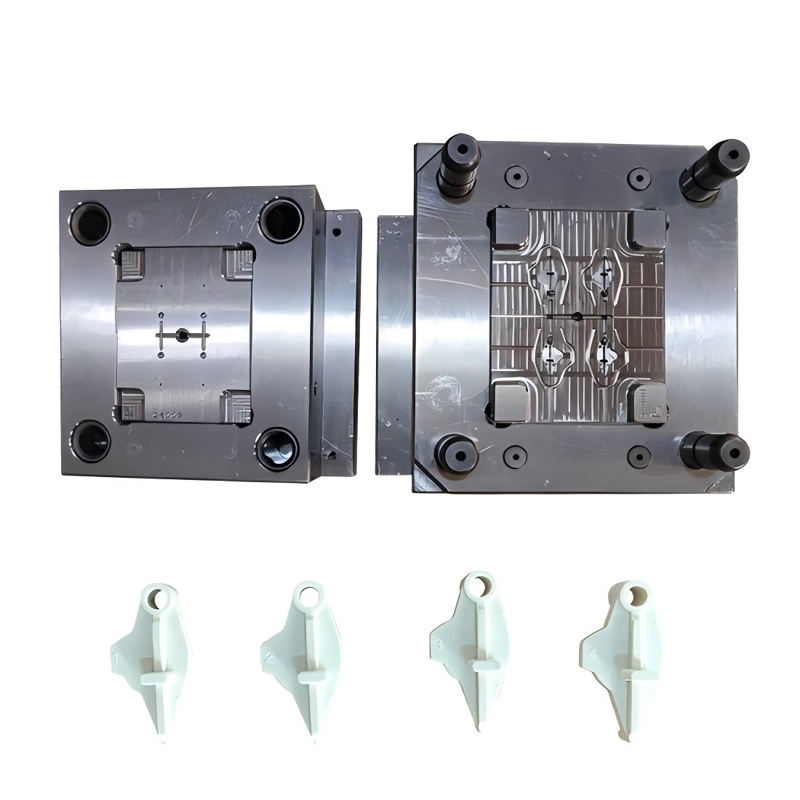

Our plastic injection molding mold for medical components is engineered for precision and adheres to the highest quality and regulatory standards. Ideal for high-volume production, this mold offers cost-effective manufacturing solutions while accommodating a variety of medical-grade materials. At All-Plastics, we ensure each mold is tailored to meet the specific needs of our clients, guaranteeing […]

Our precision-engineered molds for electronic housings, ensuring superior performance and durability. Leveraging advanced plastic injection molding techniques, we create custom molds tailored to your exact specifications, including surface treatments and finishing processes that enhance both functionality and aesthetics. As an ISO-certified leader in engineering, custom injection molding, and contract manufacturing, we provide bespoke solutions to […]

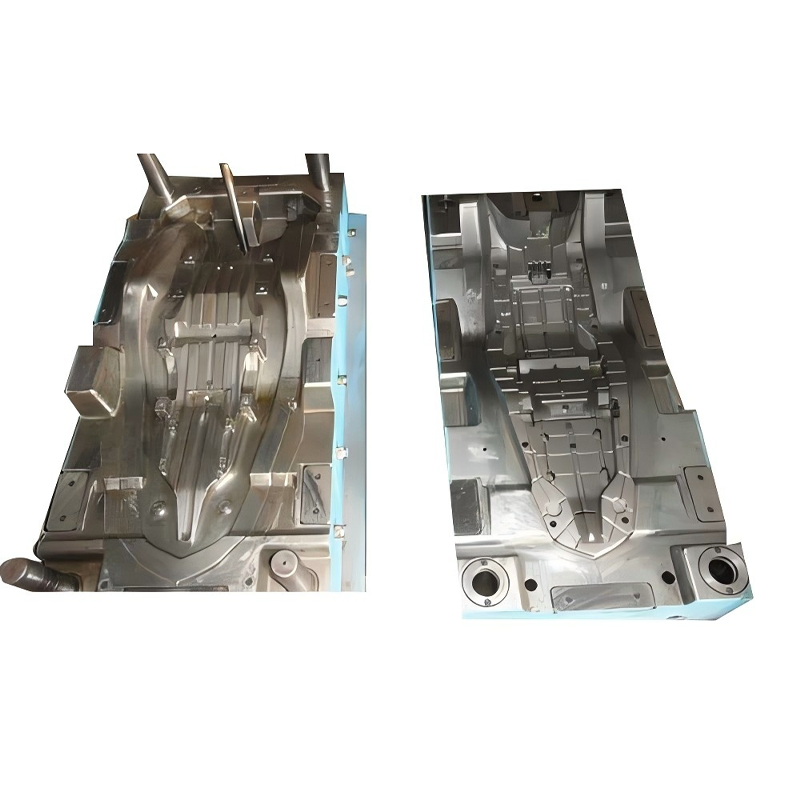

Our automotive injection molds are engineered with precision to deliver high-quality, complex components with a refined, elegant appearance. Utilizing advanced molding technologies and processes, we ensure superior durability and performance tailored to the specific needs of automotive applications. We address the common issue of internal defects and appearance shortcomings by focusing on meticulous design and […]

The plastic injection molding seat molds are designed for precision and durability, perfect for producing high-quality seating components. Engineered to meet stringent performance standards, these molds offer exceptional accuracy and long-lasting reliability. Utilizing advanced plastic injection molding techniques, our process ensures consistent results and high efficiency. We also provide custom services, including surface treatments like […]

Our advanced plastic injection molds are designed to deliver exceptional quality, meeting stringent customization requirements and enabling high-volume production with rapid prototyping capabilities. The precision-engineered molds are perfect for producing durable, reliable components essential for the latest battery technologies and new energy systems. With a focus on high performance and flexibility, our plastic injection mold […]

Our LSR injection molding housing molds are engineered for precision and durability, designed to produce high-quality housings for electronics, medical devices, and other critical applications. These molds utilize liquid silicone rubber (LSR) to create intricate, reliable parts that meet ISO9001 quality standards. We offer custom solutions, including surface treatments like ball burnishing, to enhance both […]