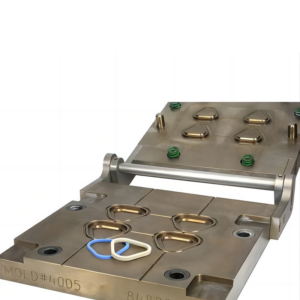

Compression rubber molds undergo various machining techniques to achieve precise shapes, facilitating the production of a diverse array of silicone rubber components. These components include O-rings, gaskets, seals, bushings, sleeves, grommets, and more.

Structure of Rubber Compression Molds:

– Core Mechanism: Silicone compression molds are designed with a dynamic core system to ensure precise and efficient molding.

– Ejection System: Equipped with an advanced ejection mechanism, this system ensures safe removal of the molded product, reducing the potential for damage or injury during extraction.

Quality Assurance & Service:

– Lifetime After-Sales Support: We offer lifetime sales-after service for all injection molds, ensuring your complete satisfaction.

– Quick Response: Our team guarantees a 24-hour response time to address all your questions and comments promptly.

– Steel Quality Warranty: Our mold steel comes with a lifetime quality warranty. For 40HRC steel, we offer a 100K shots warranty, and for 45HRC steel, a 1000K shots warranty.

– Precision Manufacturing: All products are CNC machined and prototyped according to drawings. We conduct a 100% size check before shipment to ensure accuracy.

– Comprehensive Documentation: Our engineering team provides material certification, dimension reports, design checklists, and complete mold shipment details for your peace of mind.

Variety of Moulded Products

We also specialize in a wide range of related mould products, including:

- Soap Case on Shower Stand Moulds: Designed for creating durable and aesthetically pleasing soap cases.

- Sliding Cover Moulds: Ideal for manufacturing sliding covers with precise fitting and smooth operation.

- Friction Pad Moulds: Used to produce high-quality friction pads for various automotive applications.

- Fasten Nut Moulds: Essential for creating robust and reliable fastening nuts.

- Marbles Moulds: Used for the production of decorative and functional marbles.

- Non-Slip Mat Moulds: For manufacturing mats that provide excellent grip and safety.

- Decoration Ring Moulding: Perfect for creating decorative rings with intricate designs.

- Decoration Cover of Suspension Base Moulds: Specialized for making covers that enhance the look of suspension bases.

- Sprayer Body Injection Moulds: Used in the production of durable and efficient sprayer bodies.