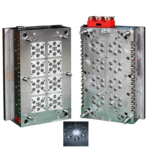

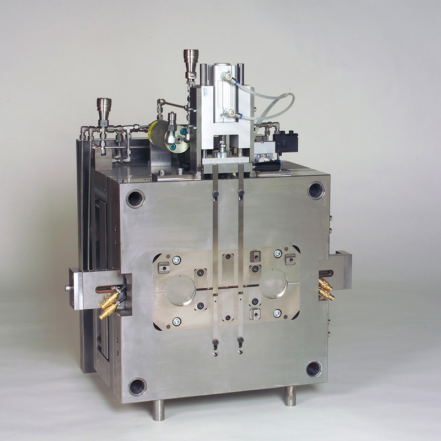

Lens tool and mould are essential components in the manufacturing process of lens-based products, such as optical lenses, LED covers, or display panels. The tool is used to shape and form the lens material, while the mould provides the precise cavity in which the lens is produced. Both the tool and mould are designed with high precision to ensure the final product meets specific optical and structural requirements. In manufacturing, these components play a crucial role in achieving consistent quality, durability, and performance, particularly for industries like electronics, automotive, and medical devices.

Basic Information

Mold Type: Plastic Injection Mold

Mold Material Options:P20, 718, 738, NAK80, S136

Mold Base Standards: HASCO, DME, MISUMI, JIS, LKM, etc.

Mold Runner System:Cold Runner / Hot Runner

Mold Gate Options:Slide Gate, Sub Gate, Pin-point Gate

Cavity:Single or Multi-Cavity

Design Software Supported:UG, PROE, CAD, SOLIDWORKS

Molding Equipment Used:CNC, Wire Cutting, Milling Machine, EDM

Compatible Raw Materials:ABS, PP, PC, PA6, PA66, PVC, POM, PMMA, PS, etc.

Packaging Method:Wooden pallet or carton

OEM Services:Available—please provide 2D/3D files or samples

Lead Time:Approximately 30 days

Quality Documentation

- ISO 9001:2015 Certification

- IATF 16949 Certification

- First Article Inspection (FAl)

- PPAP Report(Production Part Approval Process)

- Material Technical Data Sheets (TDS)

- CMM Inspection Report

- SPC Report (Statistica Process Control)

- Material Certificates

- Dimensional Inspection Report (CMM)

- DFM feedback

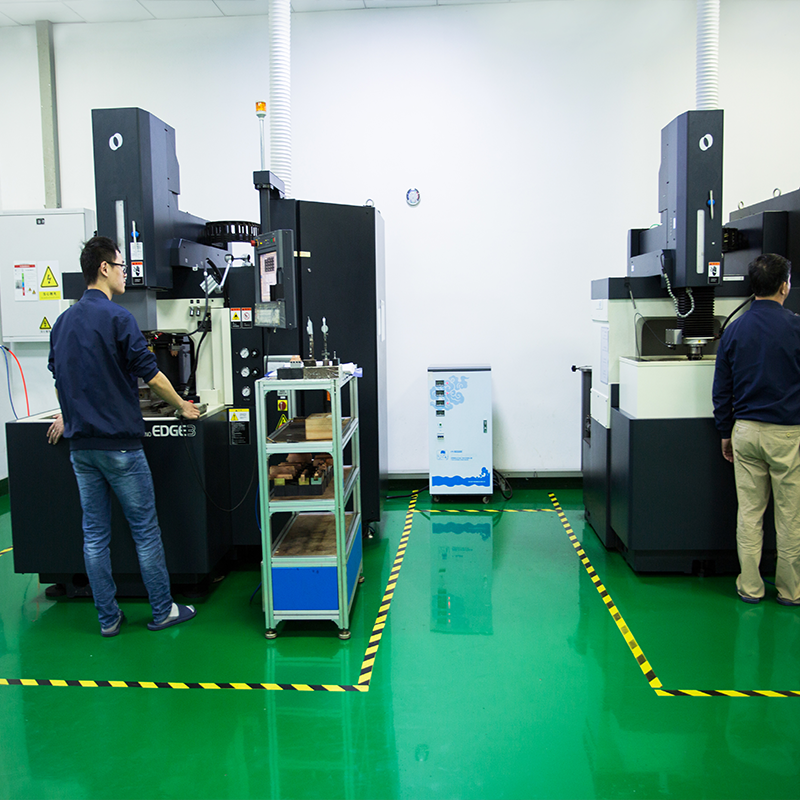

Factory Show

Our 4,500㎡ factory boasts over 20 years of OEM expertise and is equipped with world-class machinery, including Roders, Makino, Sodick, and YCM. Leveraging advanced tooling technology, we achieve micron-level precision in tool manufacturing. With ARBURG, Miltitech, and 2KM equipment, we produce ultra-precision components as small as 0.02g and as thin as 0.1mm. Our ISO-certified Class 8 medical-grade dust-free workshop ensures a controlled environment for high-quality medical device components.