Key Elements of Precision Injection Molding:

Precision is paramount in every stage of injection mold manufacturing. Here are the key factors that contribute to achieving precision in injection molding:

Design Accuracy: The design phase lays the groundwork for a successful mold. Accurate and detailed designs ensure that the final product meets specifications without defects.

Machining Excellence: CNC machining transforms designs into precise mold components. Machinists must execute with precision to maintain design specifications accurately.

Tolerance Management: Tight tolerance control ensures consistent part dimensions and quality. Deviations from specified tolerances can lead to defects.

Surface Quality: The surface finish affects the appearance and quality of molded parts. Achieving smooth, uniform surfaces minimizes defects and ensures proper material flow.

Quality Assurance: Rigorous quality checks throughout the process verify accuracy, functionality, and durability, ensuring high-quality molds.

Material Selection: Choosing the right material is crucial for mold durability and performance. Different materials offer varying hardness, wear resistance, and thermal conductivity.

Continuous Improvement: Continuous refinement of designs and processes through testing and optimization leads to enhanced mold quality and efficiency over time.

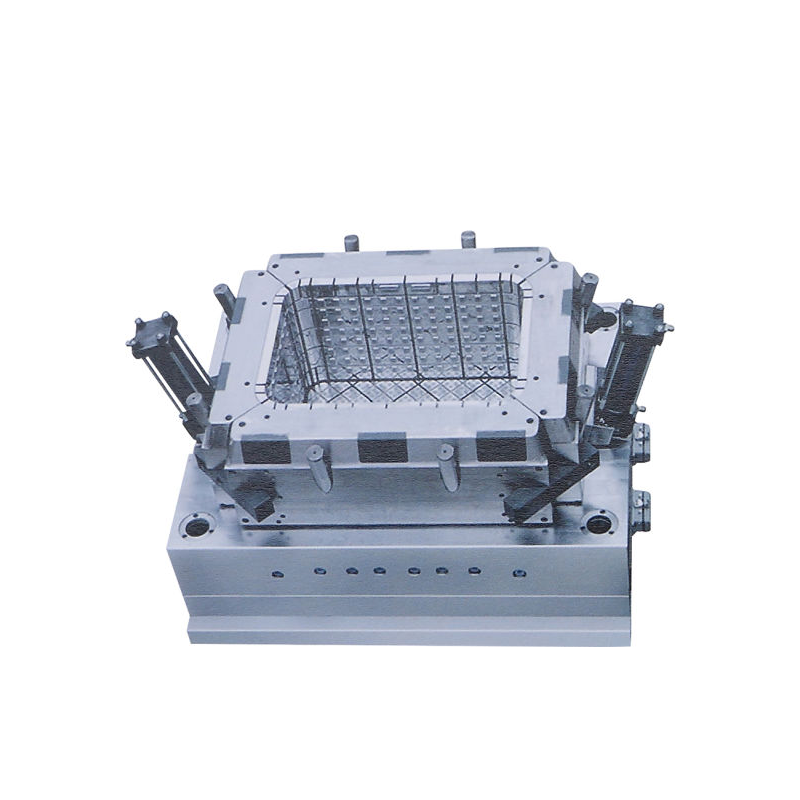

Mold Manufacturing Process:

- Product and Mold Design: Initial design phase where the product and mold are conceptualized and planned.

- Packaging: Preparation and packaging of components for the manufacturing process.

- Steel Preparation: Selection and preparation of steel for mold creation.

- Mold Testing: Conducting trials to ensure mold functionality and accuracy.

- Deep Hole Drilling: Precision drilling to create deep holes required in the mold structure.

- Assembly: Putting together various mold components.

- CNC Machining: Utilizing CNC machines for precise cutting and shaping of mold parts.

- Polishing: Final polishing to ensure a smooth finish and proper functionality of the mold.

Comprehensive Services:

We offer a complete solution from initial concept to finished product, transforming paper sketches into functional parts.

- Versatile molds for various plastic products

- Rapid prototyping capabilities

- Secure and expedited delivery

- High-quality products at competitive prices

- OEM support

- Exceptional service quality

- Welcoming custom designs and meeting customer specifications

- Extensive experience in mold production and design with a rigorous management system

- Outstanding after-sales support