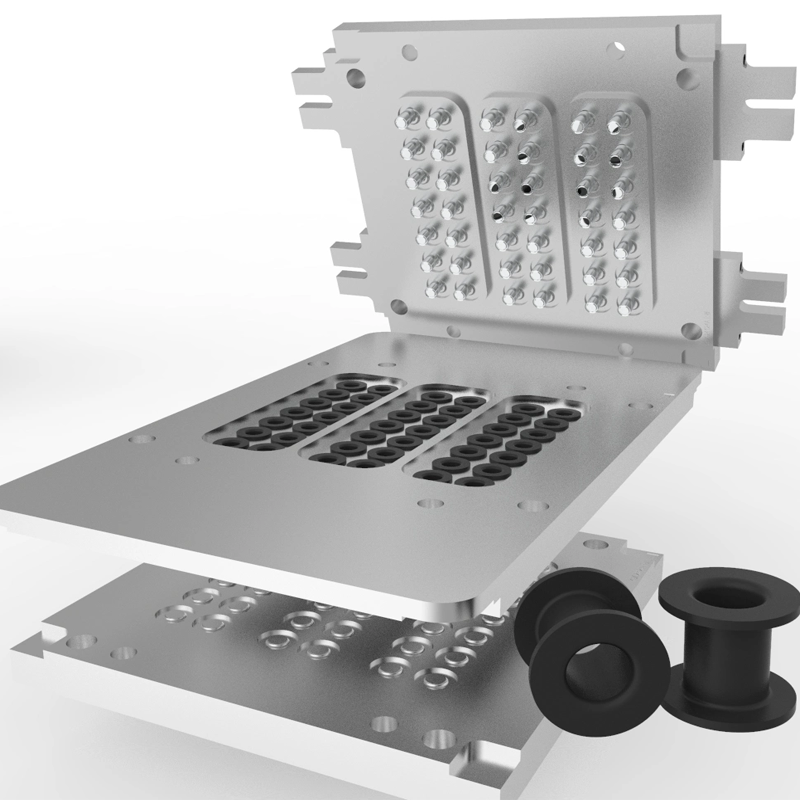

High-Quality Custom Rubber Compression Molds from Chinese Factory

Lsrmold specializes in advanced precision rubber molding techniques, including rubber compression molding, transfer molding, silicone molding, and liquid silicone rubber (LSR) injection molding.

Our in-house tool-making capabilities are designed to reduce production costs while ensuring precise tolerances. We accommodate a range of production needs, from prototype development to large-scale manufacturing runs.

Even in the absence of technical drawings, we are equipped to reverse engineer products directly from samples. Our expertise encompasses the production of molded rubber components with high accuracy, from straightforward designs to intricate and complex shapes, ensuring they meet exact specifications and perform reliably in their intended applications.

Features:

| Attribute | Details |

| Place of Origin | Xiamen |

| Brand | OEM/ODM |

| Technology | Compression Molding |

| Mould Material | Metal |

| Mold Type | Compression / Transfer / Injection |

| Design Software | CAD / PROE / MASTERCAM |

| Mould Life | 50,000 Shots |

| Cavity | Multi Cavity |

| Lead Time | 1-2 Weeks |

| Size | 3D Drawing |

| Payment | Flexible |

Other Features:

- Rapid Mold Design: Our team can quickly design molds within 3 business days after receiving customer drawings.

- Expedited Lead Times: Prototype tooling and sample production are completed within 7 days, and rubber part production molds are delivered in just 14 days.

- Comprehensive Mold Testing: Each mold is rigorously tested to ensure quality before shipment, with the option for customers to view testing videos.

- Variety of Mold Types: We specialize in a range of molds, including compression, injection, transfer, extrusion, and liquid silicone injection.

- Flexible Shipping Options: We provide various shipping methods, including sea, air, and express services like DHL, UPS, FedEx, and TNT, to accommodate your delivery needs.

- Custom Mold Making: We offer OEM/ODM services, allowing us to customize molds according to your specific requirements.

Manufacturing Process:

- Design Phase:

– In this initial stage, we conceptualize and engineer the design for custom rubber tooling and compression molds. Detailed blueprints and specifications are created based on client requirements and product specifications.

- Material Preparation:

– After finalizing the design, we select high-quality materials for mold construction. Durable rubber and metal materials are chosen to ensure precision and longevity in the manufacturing process.

- Tooling Fabrication:

– The fabrication process involves creating the tooling components using techniques such as CNC machining, milling, and turning. These methods shape the mold cavity and core to exact design specifications.

- Mold Assembly:

– The fabricated components are assembled to form the complete mold. This step includes fitting the cavity, core, inserts, and other components with precision to ensure proper functionality.

- Testing and Adjustment:

– Rigorous testing is conducted to evaluate the mold’s performance and accuracy. Sample materials are used in test runs to assess molding quality and make necessary adjustments to optimize functionality.

- Final Inspection and Quality Assurance:

– A final inspection ensures the molds meet quality and precision standards. This includes checking dimensional accuracy, surface finish, and overall integrity of the mold components.

- Delivery and Installation:

– Once testing and inspection are complete, the molds are packaged and delivered to the client. We offer installation support to ensure proper setup and integration into the production process.