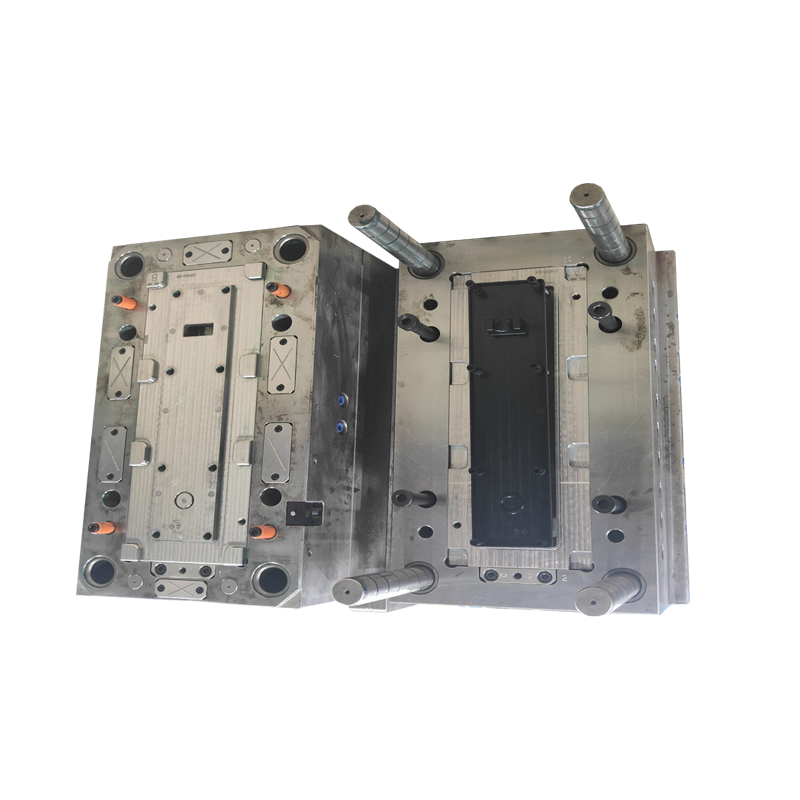

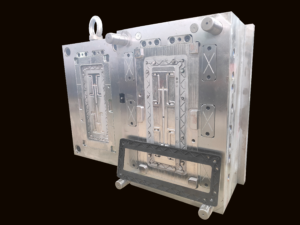

High-Quality Custom Bathroom Faucet Switches Mold from Chinese Manufacturer

Overview:

Our precision mold for bathroom faucet switches is engineered with cutting-edge injection molding technology. This advanced mold ensures the production of durable, high-precision switches designed for efficiency and water conservation. By emphasizing consistency and eco-friendly manufacturing, we produce top-quality bathroom faucet switches that meet rigorous performance standards.

Features:

| Item | Description |

| Runner | Cold Runner |

| Steel Hardness | HRC38~42 |

| Mould Cavity | Single Cavity |

| Mould Installation | Manual |

| Molding Surface Treatment | Polishing |

| Mould Life | 100,000 to 300,000 Times |

| Plastic Product Material | PPS |

| Production Process | Injection Molding |

| Warranty Period | 1 Year or 100,000 Shots (Includes Free Parts or Service for Mold Issues within Warranty Period) |

| Mould Precision | ±0.01mm |

| Ejection System | Motor/Hydraulic Cylinder/Stripping Plate/Angle Pin, etc. |

| Cooling System | Water Cooling or Beryllium Bronze Cooling, etc. |

| Optional Plastic Materials | ABS, PPS, GPPS, HIPS, AS, MS, PMMA, PC, PA6, PA66, PA+GF, PVC, PP, PE, TPE, TPU, TPR, LCP, PBT, PETG, PC/ABS, POM, PPE, PPO, etc. |

| Mould Base | Standard Mould Base, LKM, HASCO, DME, etc. |

| Fast Mold Design | Within 1-3 Working Days after Receiving Customer’s Drawings |

| Mould Testing | All Moulds are Well Tested before Shipment, Video Testing Available |

| Mould Lead Time | Plastic Moulds: 3-4 Weeks after Mold Design Confirmation |

| Minimum Order | Small Orders Accepted |

| Mould Making Service | OEM/ODM Service Available |

| Mould Safe Packing | Strong Wooden Pallets to Avoid Damages during Transportation |

| Quality System | ISO9001, SGS, TS16949 |

| Specification | Depends on Clients’ Requirements |

| Origin | Xiamen, China |

Services Provided:

We offer a comprehensive suite of services, including:

– Mold Fabrication: Precision mold creation tailored to specific requirements.

– Plastic Injection Molding: High-quality production with advanced molding techniques.

– Aluminum/Zinc Die Casting: Robust die-casting solutions for durable components.

– CNC Machining: Accurate and efficient machining using state-of-the-art CNC technology.

– Sheet Metal Fabrication: Custom metal fabrication with precise cutting and forming.

– Surface Finishing: Professional surface treatments for enhanced aesthetics and performance.

– Assembly and Packaging: Complete assembly services and customized packaging solutions.

Quality Assurance:

– Lifetime Support: Comprehensive lifetime support is provided for all injection molds.

– 24/7 Responsiveness: Inquiries and feedback are addressed promptly within 24 hours.

– Mold Steel Warranty: Steel quality is guaranteed throughout its lifespan, with warranties for 100,000 shots for 40HRC steel and 1,000,000 shots for 45HRC steel.

– Precision Prototypes: CNC-machined prototypes are crafted to exact specifications and undergo 100% dimensional verification before shipping.

– Documentation: Our engineering team supplies material certifications, dimension reports, and design checklists with each mold shipment.

Production Process for Molds/Moulds/Tooling:

- Design for Manufacturability (DFM) Analysis

– Generate a detailed DFM report to evaluate design feasibility, identify potential manufacturing issues, and optimize moldability and cost-efficiency.

- Mold Design

– Develop precise mold designs using advanced CAD software, defining mold geometry, cavity layout, and essential features in alignment with product specifications.

- Material Selection

– Select high-grade materials such as steel alloys or specialized polymers based on product requirements and intended application to ensure durability and performance.

- CNC Machining

– Employ CNC (Computer Numerical Control) technology to accurately cut and shape mold components, ensuring high precision and consistency.

- Laser Cutting

– Utilize laser cutting for detailed and intricate cuts in mold components, providing high precision and clean edges crucial for complex mold designs.

- Wire EDM Cutting

– Apply Wire EDM (Electrical Discharge Machining) for cutting fine details and complex shapes in mold components, essential for achieving high precision and fine tolerances.

- Grinding

– Perform grinding to refine mold surfaces and achieve smooth finishes, enhancing accuracy and removing residual machining marks.

- Mold Assembly

– Assemble all mold components, including cavities, cores, and inserts, into a complete mold structure, ensuring precise fitting and functionality.

- Stamping

– Implement stamping processes to add specific features, logos, text, or other surface details to the mold as required.

- Sample Inspection

– Conduct thorough inspections of sample molds to ensure they meet design specifications and quality standards, testing for functionality, accuracy, and overall performance.

- Mass Production

– Once samples are approved, commence mass production, ensuring consistency and high quality across all units.

- Cleaning

– Clean molds meticulously to remove any debris or contaminants from the manufacturing process, maintaining quality and ensuring optimal performance.

- Packaging

– Securely package completed molds to prevent damage during transport, using protective materials and proper labeling for safe and accurate delivery.

- Delivery

– Coordinate the logistics for timely and secure delivery of molds to the client’s location, ensuring safe transportation.

- After-Sales Support

– Offer comprehensive after-sales service, including maintenance, troubleshooting, and adjustments to ensure continued mold performance and client satisfaction.