Description:

High Precision Plastic Injection Molds for Shower Faucet Applications are engineered to produce durable, leak-proof components for modern plumbing systems. Made from high-grade tool steels (e.g., P20, H13) or aluminum alloys, these molds utilize advanced CNC machining, EDM texturing, and rigorous QC protocols to ensure micron-level accuracy. Our factory specializes in custom designs tailored to complex geometries and material requirements (e.g., POM, PA66, or glass-fiber-reinforced thermoplastics), backed by ISO 9001:2015 certification and compliance with ASME BPE standards for sanitary applications. Offering one-stop service from prototyping to mass production, we integrate automated IMM machines, mold-flow analysis software, and post-molding inspections to guarantee flawless performance. Ideal for OEMs seeking corrosion-resistant, high-tolerance faucet parts with fast turnaround.

Basic Information:

- Mold Type: Plastic Injection Mold

- Mold Material Options: P20, 718, 738, NAK80, S136

- Mold Base Standards: HASCO, DME, MISUMI, JIS, LKM, etc.

- Mold Runner System: Cold Runner / Hot Runner

- Mold Gate Options: Slide Gate, Sub Gate, Pin-point Gate

- Cavity: Single or Multi-Cavity

- Design Software Supported: UG, PROE, CAD, SOLIDWORKS

- Molding Equipment Used: CNC, Wire Cutting, Milling Machine, EDM

- Compatible Raw Materials: ABS, PP, PC, PA6, PA66, PVC, POM, PMMA, PS, etc.

- Packaging Method: Wooden Pallet or Carton

- OEM Services: Available — Please provide 2D/3D files or samples

- Lead Time: Approximately 30 days

Surface Coating Options:

- TiN (Titanium Nitride) Coating: Enhances wear resistance and reduces friction via PVD deposition; ideal for high-temperature, abrasive environments.

- DLC (Diamond-Like Carbon) Coating: Provides ultra-low friction, corrosion resistance, and anti-adhesion properties for extended mold life in humid conditions.

- Hard Chrome Plating: Delivers superior corrosion resistance and uniform surface hardness (up to 70 HRC) for molds exposed to harsh detergents or water.

- PVD (Physical Vapor Deposition) Multilayer Coatings: Combines materials like CrN or AlCrN for balanced hardness, thermal stability, and release performance in complex geometries.

Benefits of Our Mold:

- Superior Durability and Extended Mold Lifespan

- Outstanding Precision and Smooth Surface Finish

- Efficient Maintenance and User-Friendly Operation

- Crafted from High-Quality Steel Materials

Quality Assurance:

Quality Assurance for high-precision plastic injection mold suppliers (shower faucet applications) ensures compliance with strict tolerances (±0.005mm), durability, and material safety. This includes verifying tool steel (P20, H13) or aluminum alloy quality via XRF spectrometers and Rockwell hardness testers, dimensional accuracy checks using CMM machines and optical comparators, and surface finish audits per SPI standards with profilometers. Molds undergo thermal cycling, pressure testing (1,500+ PSI), and fatigue simulations to guarantee performance. Certifications like ISO 9001:2015, ASME BPE, and RoHS/REACH are mandatory, supported by mold-flow analysis software (e.g., Moldflow®) and automated vision systems for defect detection. Full traceability (PPAP/DFMEA documentation) and material safety reports are provided to meet OEM requirements.

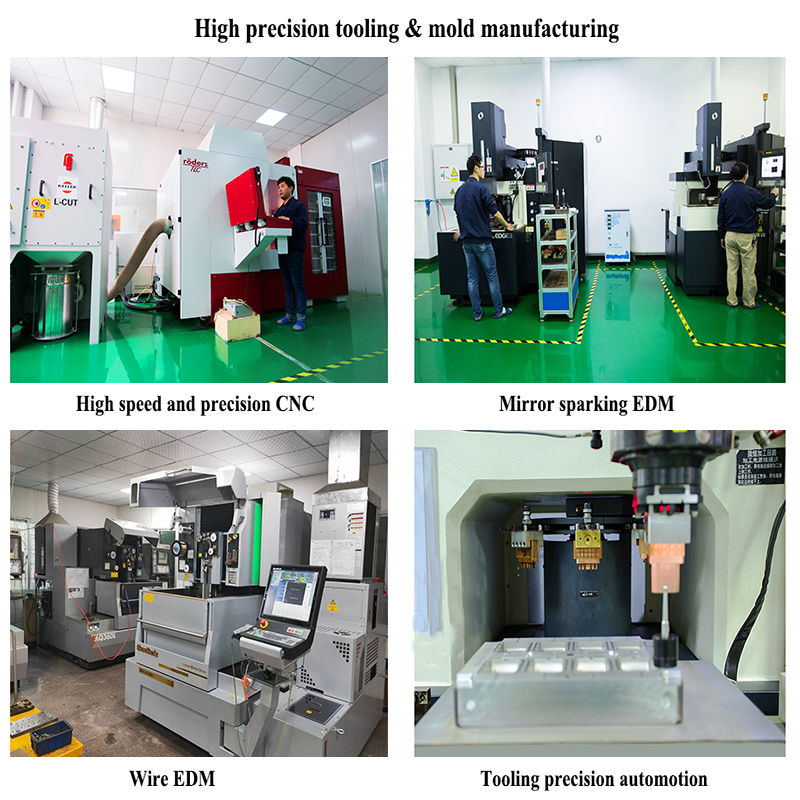

Factory Show:

Our advanced manufacturing facility is equipped with cutting-edge technologies, including CNC machining, Mirror EDM, EDM, and Slow-Speed Wire Cut (WC), ensuring the highest precision in mold production. We operate a fleet of 15 rubber compression molding machines and 2 LSR injection molding machines, optimizing both production capacity and efficiency.

To maintain the highest quality standards, we utilize state-of-the-art tools, such as 3D projectors, sealing testers, durometers, and elasticity measurement devices, all managed by our certified quality control team. Our operations adhere to ISO 9001 and IATF 16949 certifications, guaranteeing consistent quality and reliability.

In addition, we incorporate automated systems like AutoDryers, high-speed doming machines, and die-cutting machines to further enhance production accuracy and efficiency, reinforcing our commitment to delivering superior products with optimal performance.