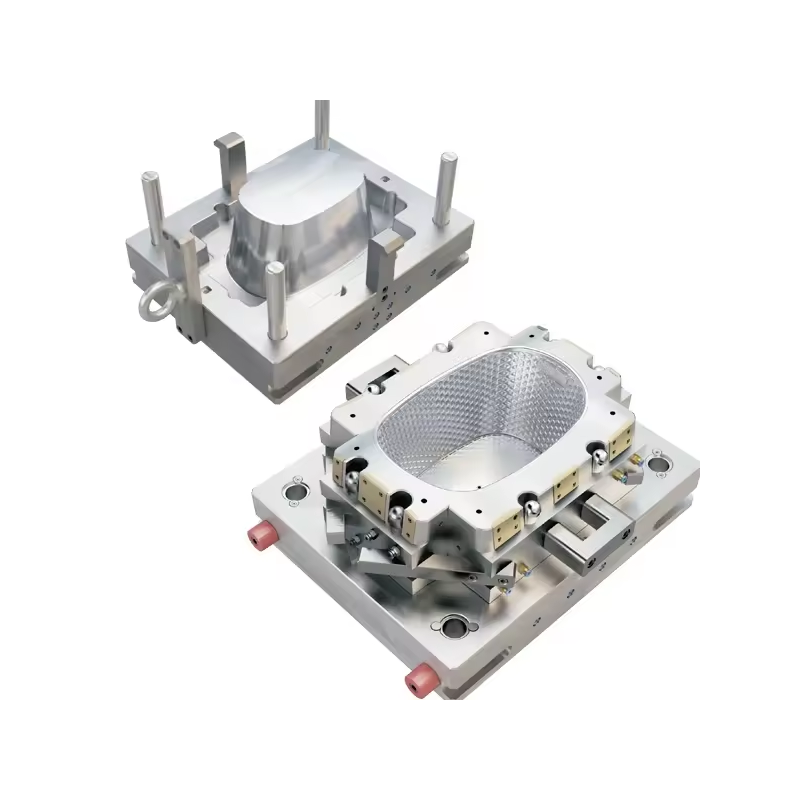

Overview:

Our square hollow molds are engineered to consistently produce uniform hole sizes with no deviation. They offer customizable dimensions to accommodate specific requirements, including tailored female sizes. Additionally, our molds can be integrated into advanced mechanisms to facilitate efficient hollowing processes, which streamlines basket production. This optimization not only minimizes product wastage but also enhances overall mold output. By incorporating our molds into your production line, you can achieve greater precision and efficiency, ultimately improving your manufacturing performance.

Characteristics:

| Shaping Mode | Plastic Injection Mold |

| Model Number | Silicone Vegetables Fruit Basket Mold |

| Runner Type | Cold/Hot Runner |

| Installation Type | Fixed |

| Certification | ISO |

| Customization | Available |

| Mold Life | 500,000 to 1,000,000 Shots |

| Transport Packaging | Wooden Box |

| Specification | Customization |

| Trademark | OEM |

| Place of Origin | Xiamen, China |

| Production Capacity | 50 Sets per Month |

| Plastic Material | ABS, PP, PC, PVC, POM, TPU, PC, PEEK, HOPE, NYLON, Silicone Rubber, etc. |

| Mold base | LKM, HASCO, DME, self-control etc. |

| Surface Finish | Polishing/smooth, Texture/frosted, Printing, Painting, Plating |

| Our Equipment | High speed CNC, standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic injection Molding Machine from 30-1400T available. |

| Main Fields | Security equipment, Intelligent instrument, Consumer electronics, Medical device, Home appliance, Automotive parts, Kitchen equipment, Robots, etc. |

The Selection Of Material Steps:

We offer a wide range of materials, and you can be involved in the selection process. How would you prefer to choose?

- Define Mold Requirements: Determine application, size, shape, complexity, and volume needs.

- Material Properties Assessment: Evaluate strength, hardness, thermal, and corrosion resistance properties.

- Material Options: Choose from tool steels, alloys, stainless steels, or aluminum.

- Manufacturing Process Compatibility: Ensure machinability and suitable heat treatment capabilities.

- Cost and Availability: Balance material costs with performance and supply constraints.

- Quality Assurance: Conduct testing and verify compliance with standards.

- Final Selection and Approval: Test prototype, validate performance, and secure final approval.

The Production Process of Molds:

Next is our manufacturing process, which we handle with great care and professionalism.

- Evaluate design feasibility and challenges.

- Create precise designs with CAD.

- Choose materials based on requirements.

- Cut and shape mold parts precisely.

- Perform intricate, precise cuts.

- Achieve detailed shapes and tolerances.

- Refine surfaces for smooth finishes.

- Fit components into complete structure.

- Add features or impressions to molds.

- Verify mold accuracy and performance.

- Produce molds in large quantities.

- Remove debris and contaminants thoroughly.

- Securely package molds for transport.

Excellent After-Sales Service:

- Ongoing Support: Continuous assistance for issues.

- Maintenance Services: Regular upkeep for optimal performance.

- Troubleshooting: Expert help for resolving problems.

- Modifications: Adjustments for changing requirements.

- Customer Feedback: Enhance service based on feedback.

We ensure your customization process is seamless from start to finish.