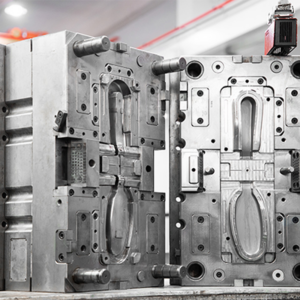

Custom Tooling And Molding Electronics Injection Mold

We specialize in creating custom plastic injection molds and parts.Tooling and Molding Electronics Injection Mold is a critical process in the manufacturing of electronic components. It combines precise mold creation with efficient injection molding techniques to produce high-quality, consistent, and cost-effective parts. This process is indispensable in various industries, from consumer electronics to automotive and medical devices, ensuring the production of reliable and durable components.We offer a full suite of services, from tooling to mass production of parts.

Details:

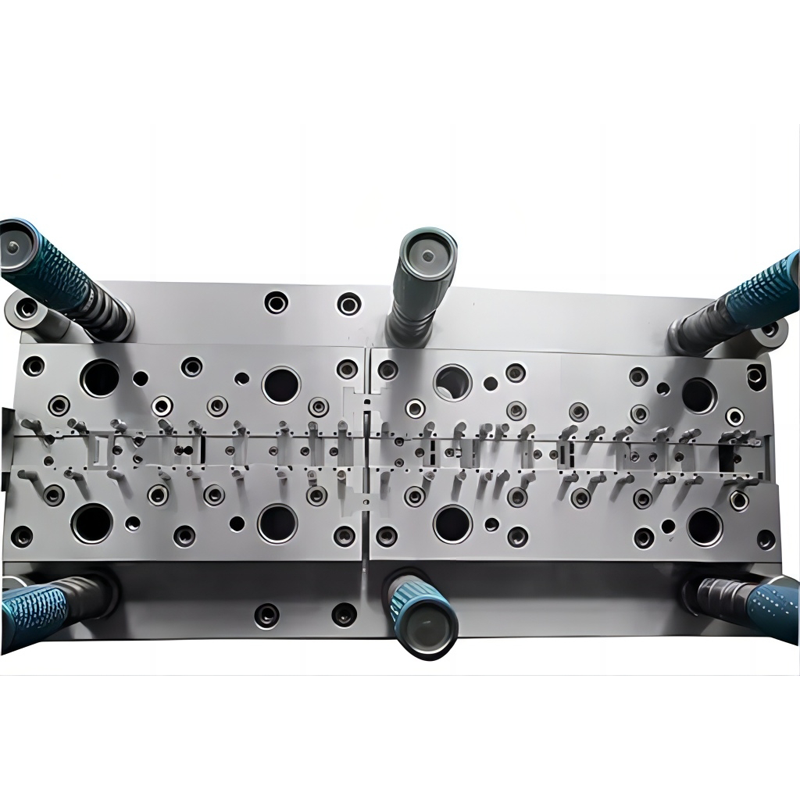

| Mould Type | Electronics Injection Mold |

| Mould Material | P20/718/738/NAK80/S136 |

| Mould Base | HASCO, DME, MISUMI, JIS, LKM, etc |

| Mould Runner | Cold Runner/Hot Runner |

| Mould Gate | Slide Gate/Sub Gate/Pin-point Gate |

| Cavity | Single/Multi Cavity |

| Designing Software | UG/PROE/CAD/SOLIDWORKS |

| Moulding Equipment | CNC, Wire Cutting, Milling Machine, EDM |

| Raw Material | ABS, PP, PC, PA6, PA66, PVC, POM, PMMA, PS, etc |

| Package Way | Wooden Pallet, Carton |

| OEM/ODM | Welcome and please offer 2D/3D file or sample |

| Lead Time | About 20 days |

Key Elements of Precision Injection Molding:

Precision is paramount in every stage of injection mold manufacturing. Here are the key factors that contribute to achieving precision in injection molding:

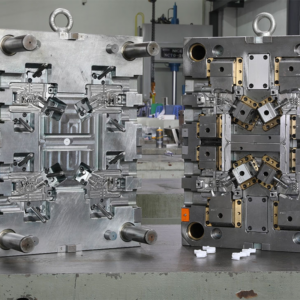

Design Accuracy: The design phase lays the groundwork for a successful mold. Accurate and detailed designs ensure that the final product meets specifications without defects.

Machining Excellence: CNC machining transforms designs into precise mold components. Machinists must execute with precision to maintain design specifications accurately.

Tolerance Management: Tight tolerance control ensures consistent part dimensions and quality. Deviations from specified tolerances can lead to defects.

Surface Quality: The surface finish affects the appearance and quality of molded parts. Achieving smooth, uniform surfaces minimizes defects and ensures proper material flow.

Quality Assurance: Rigorous quality checks throughout the process verify accuracy, functionality, and durability, ensuring high-quality molds.

Material Selection: Choosing the right material is crucial for mold durability and performance. Different materials offer varying hardness, wear resistance, and thermal conductivity.

Continuous Improvement: Continuous refinement of designs and processes through testing and optimization leads to enhanced mold quality and efficiency over time.