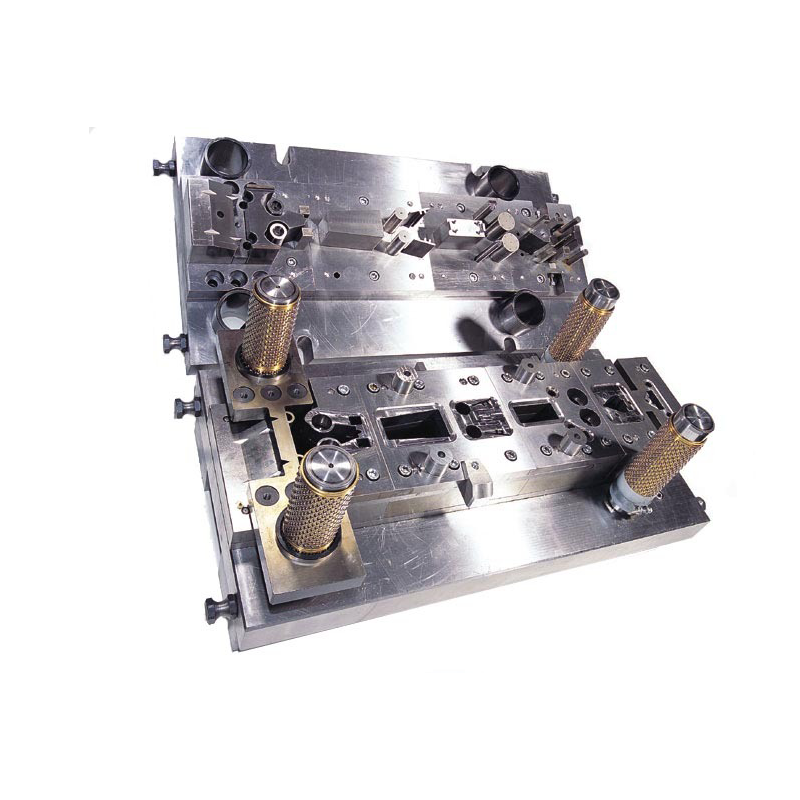

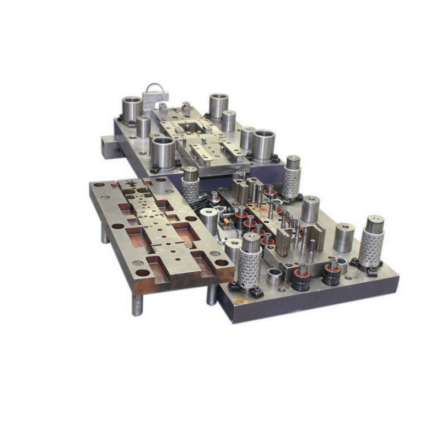

Tool Die and Mould Making is a precision manufacturing process used to create custom tools, dies, and molds for producing high-quality parts in industries like automotive, consumer goods, and electronics. This process involves designing and fabricating tools that can shape, cut, or form materials such as metal, plastic, or rubber. With advanced techniques like CNC machining and injection molding, tool die and mould making ensures high accuracy, durability, and cost efficiency for mass production. It is essential for creating complex components with tight tolerances, providing a foundation for high-performance manufacturing.

Basic Information

Mold Type: Plastic Injection Mold

Mold Material Options:P20, 718, 738, NAK80, S136

Mold Base Standards: HASCO, DME, MISUMI, JIS, LKM, etc.

Mold Runner System:Cold Runner / Hot Runner

Mold Gate Options:Slide Gate, Sub Gate, Pin-point Gate

Cavity:Single or Multi-Cavity

Design Software Supported:UG, PROE, CAD, SOLIDWORKS

Molding Equipment Used:CNC, Wire Cutting, Milling Machine, EDM

Compatible Raw Materials:ABS, PP, PC, PA6, PA66, PVC, POM, PMMA, PS, etc.

Packaging Method:Wooden pallet or carton

OEM Services:Available—please provide 2D/3D files or samples

Lead Time:Approximately 30 days

One-Stop Service for Moulds

– Initial Consultation: Assess client needs and provide expert advice on design, material selection, and tooling requirements.

– Custom Design: Create tailored designs based on client specifications, utilizing advanced CAD and 3D modeling tools.

– Tooling Fabrication: Manufacture precision molds and tooling using high-quality materials and state-of-the-art machinery.

– Prototype Development: Produce and refine prototypes to validate designs and ensure they meet client expectations.

– Comprehensive Testing: Conduct rigorous testing to verify mold performance, including functionality, durability, and accuracy.

– Surface Finishing: Apply various surface treatments such as polishing, coating, and texturing to achieve desired aesthetics and functionality.

– Production Readiness: Prepare molds for mass production, including final adjustments and quality checks.

– Logistics Management: Handle the complete logistics process, including packaging and shipping to ensure timely and safe delivery.

– Installation Support: Provide guidance and assistance with mold installation and setup to integrate seamlessly into client production lines.

– Quality Assurance: Implement stringent quality control measures throughout the process to ensure all products meet industry standards and client specifications.

– After-Sales Service: Offer ongoing support for maintenance, troubleshooting, and modifications to ensure long-term satisfaction and optimal performance.