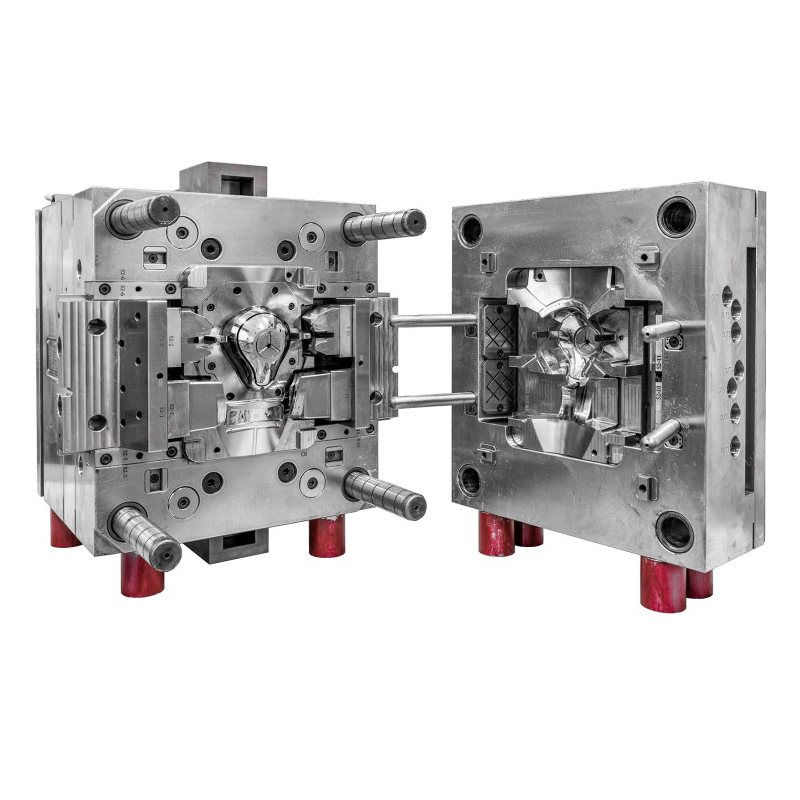

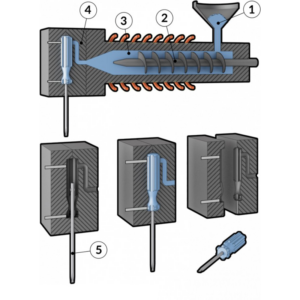

Our plastic overmolding tooling solutions are meticulously designed for precision in multi-material and multi-component applications, ensuring seamless bonding between materials such as thermoplastics and elastomers. Leveraging cutting-edge CNC machining, EDM technology, and specialized surface treatments, we produce tooling that guarantees superior durability and consistent performance. Every tool is subjected to thorough quality checks at each stage of production to ensure reliability and extended lifespan. As an OEM provider, we accommodate custom designs and large-scale production needs. Our plastic overmolding tooling enhances product functionality, shortens assembly time, and elevates visual appeal—all while maintaining a focus on cost-effectiveness and punctual delivery.

One-Stop Service for Molds

– Initial Consultation: Assess client needs and provide expert advice on design, material selection, and tooling requirements.

– Custom Design: Create tailored designs based on client specifications, utilizing advanced CAD and 3D modeling tools.

– Tooling Fabrication: Manufacture precision molds and tooling using high-quality materials and state-of-the-art machinery.

– Prototype Development: Produce and refine prototypes to validate designs and ensure they meet client expectations.

– Comprehensive Testing: Conduct rigorous testing to verify mold performance, including functionality, durability, and accuracy.

– Surface Finishing: Apply various surface treatments such as polishing, coating, and texturing to achieve desired aesthetics and functionality.

– Production Readiness: Prepare molds for mass production, including final adjustments and quality checks.

– Logistics Management: Handle the complete logistics process, including packaging and shipping to ensure timely and safe delivery.

– Installation Support: Provide guidance and assistance with mold installation and setup to integrate seamlessly into client production lines.

– Quality Assurance: Implement stringent quality control measures throughout the process to ensure all products meet industry standards and client specifications.

– After-Sales Service: Offer ongoing support for maintenance, troubleshooting, and modifications to ensure long-term satisfaction and optimal performance.

Advatages of Our Product

- High Dimensional Accuracy: Our molds are designed and manufactured with precise engineering to ensure exact replication of product specifications, reducing the risk of defects and minimizing the need for post-production adjustments.

- Enhanced Durability: Constructed from high-quality steel and treated with advanced surface finishes, our molds are engineered to withstand high-pressure conditions and extensive use, extending their service life and reliability.

- Superior Surface Quality: We offer a range of surface treatments, including polishing and texturing, to achieve optimal finish and functionality. This ensures that the final products exhibit excellent surface quality and consistency.

- Efficient Heat Distribution: Our molds are designed with effective cooling and heating systems, such as optimized runner layouts and temperature control, to enhance production efficiency and maintain uniformity in the final product.

- Versatile Application: Our molds support a wide range of plastic materials and processes, including complex geometries and intricate designs, making them suitable for various industries and applications.