Precision Plastic Moulding Expertise

With extensive experience in producing a wide range of precision plastic mouldings, we specialize in several key areas:

– Insert & Outsert Mouldings: Expertise in manufacturing components such as plugs, moulded terminals, thumb nuts, and electrical connectors.

– Intricate & Micro Precision Mouldings: Proficiency in creating highly detailed and extremely small parts, including hearing aid components, speedometer parts, and medical devices.

– Threaded Precision Injection Mouldings: Skilled in producing precision-engineered components like instrument gears, layshafts, and ratchet wheels.

– Tinted, Coloured & Clear Plastic Mouldings: Capable of delivering high-quality mouldings for backlit instrument dials, emergency lighting, and vehicle light covers, with options for tinted, coloured, or clear finishes.

– Two-Part Overmoulding & Thermoplastic Rubber Mouldings: Specialized in overmoulding and thermoplastic rubber mouldings, such as soft grip handles, cable strain reliefs, and protective rubber sleeves.

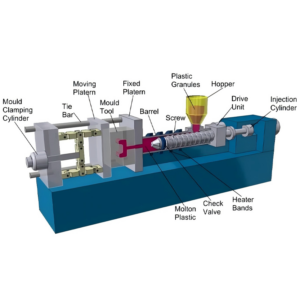

Mould Manufacturing Process

– Inquiry Reception

– Receive customer inquiries promptly.

– Quotation and Details

– Provide price offers or detailed information within 16 hours.

– Drawing Submission

– Customers provide 2D/3D drawings and additional mold details.

– Order Confirmation

– Confirm order details including quality, price, material, delivery time, payment terms, etc.

– Production Preparation

– Prepare for production according to client’s requirements.

– Mold Detail Confirmation

– Clients confirm the specific details of the mold.

– Surface Shaping

– Perform operations such as drilling holes, high-speed carving, wire cutting, EDM, etc.

– Sample Testing

– Arrange for test mold production and send samples to customers for evaluation.

– Feedback and Adjustments

– If clients are not satisfied with the samples, provide feedback for adjustments.

– Repair and Finishing

– Conduct repairs, polishing, and texture application as necessary.

– Sample Approval

– Send revised samples until customers’ confirmation is obtained.

– Delivery

– Arrange delivery by sea, air, etc., as per customer preference.

Color Expertise

We specialize in providing tinted, colored, and clear plastic mouldings, with a focus on delivering high-quality color solutions at competitive prices. Whether for short or long production runs, our expertise ensures vibrant, consistent, and precise color matching tailored to your specific needs. Explore our color solutions to learn more about how we can enhance your products with our expert services.