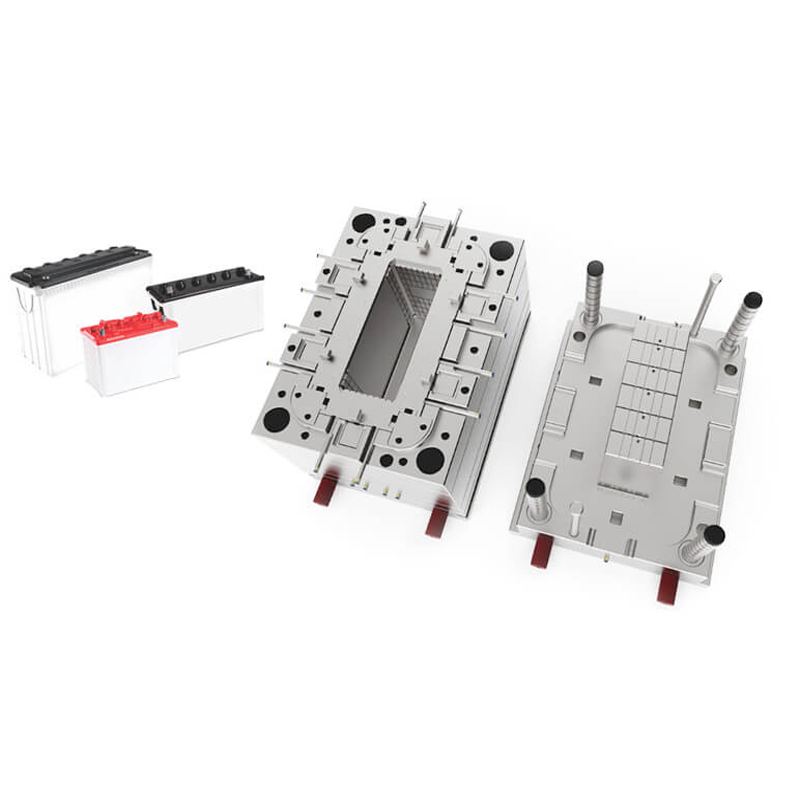

Our advanced plastic injection molds are designed to deliver exceptional quality, meeting stringent customization requirements and enabling high-volume production with rapid prototyping capabilities. The precision-engineered molds are perfect for producing durable, reliable components essential for the latest battery technologies and new energy systems. With a focus on high performance and flexibility, our plastic injection mold solutions ensure efficient production processes, from tailored prototypes to extensive manufacturing runs.

Features:

| Attribute | Value |

| Mould Type | Plastic Injection Mold |

| Mould Material | P20/718/738/NAK80/S136 |

| Mould Base | HASCO, DME, MISUMI, JIS, LKM etc |

| Mould Runner | Cold Runner/ Hot Runner |

| Mould Gate | Slide Gate/Sub Gate/Pin-point Gate |

| Cavity | Single / Multi Cavity |

| Designing Software | UG/PROE/CAD/SOLIDWORKS |

| Moulding equipment | CNC, Wire Cutting, Milling Machine, EDM |

| Raw-material | ABS, PP, PC, PA6, PA66, PVC, POM, PMMA, PS etc |

| Package way | Wooden pallet, carton |

| OEM | Welcome and please offer 2D/3D file or sample |

| Lead time | About 30 days |

Advantages of Our Mold/Mould/Tooling:

-

Superior Quality:

– Our molds are manufactured using high-grade materials and state-of-the-art techniques, ensuring exceptional durability, precision, and longevity. Each mold undergoes rigorous quality control checks to meet stringent industry standards.

-

Customization:

– We offer highly customizable mold designs tailored to meet specific client requirements. Our team works closely with clients to develop molds that align perfectly with their unique production needs and specifications.

-

Advanced Technology:

– Utilizing the latest in CNC machining, laser cutting, and precision engineering, our molds are crafted with unparalleled accuracy. Our advanced technology ensures consistent, high-quality output and reduces production downtime.

-

Rapid Prototyping:

– We provide quick turnaround times for prototypes, allowing clients to test and validate their designs swiftly. This accelerates the product development process and brings products to market faster.

Surface Treatment Options:

-

Polishing:

This process refines the mold’s surface finish, reducing friction and enhancing both aesthetics and functionality, resulting in high-quality, defect-free components.

-

Texturing:

Texturing applies intricate patterns to the mold surface, creating unique finishes such as leather-like textures and fine grooves, enhancing visual appeal and functionality.

-

Hard Chrome Plating:

This treatment increases the mold’s hardness and wear resistance, particularly beneficial for high-friction applications, ensuring longer tool life and consistent product quality.

-

Nitriding:

Nitriding diffuses nitrogen into the mold’s surface, forming a hard, wear-resistant layer essential for high-stress applications, significantly improving durability and performance.

Here’s a streamlined version of the production process for plastic injection molds for auto battery boxes:

Production Process Overview

-

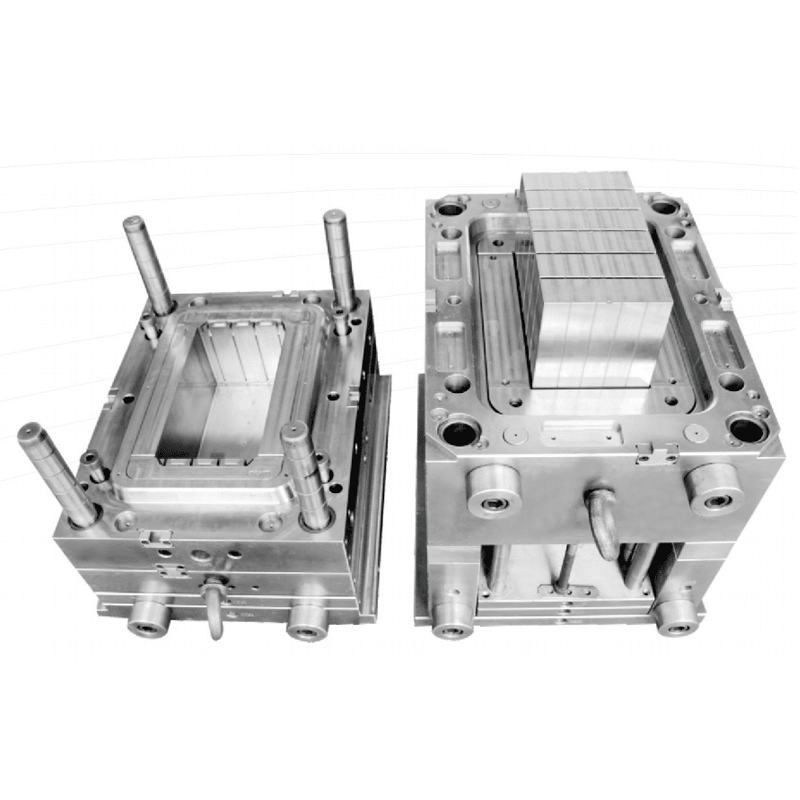

Design and Engineering

– Concept Development: Create initial design concepts based on customer requirements.

– 3D Modeling: Use CAD software for detailed mold design and visualization.

– Mold Flow Analysis: Simulate plastic flow to identify potential issues.

-

Material Selection

– Choose Materials: Select high-quality steel or aluminum (e.g., P20, H13, S136) for durability and heat resistance.

-

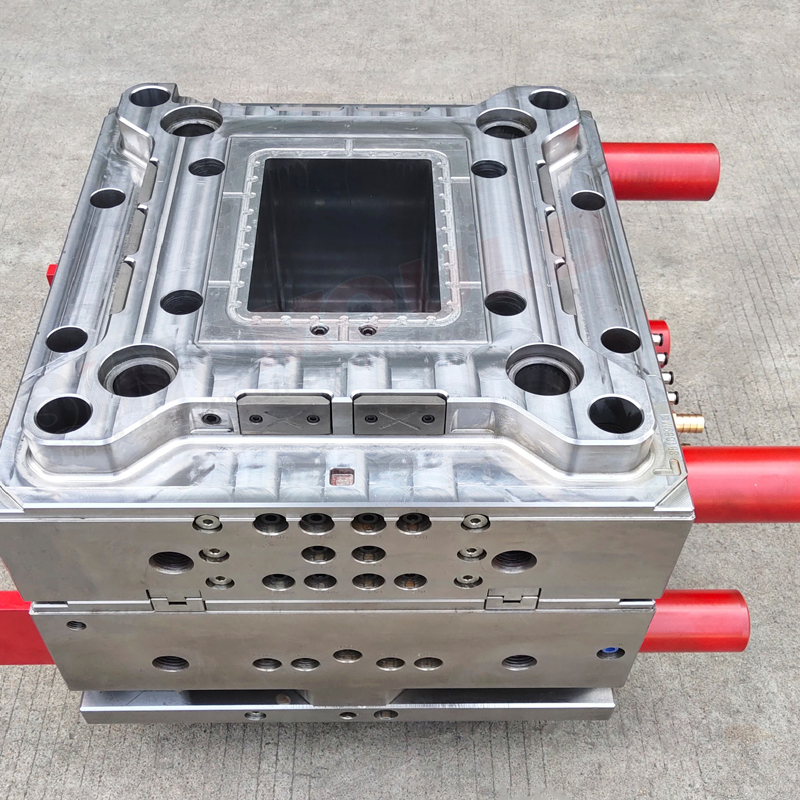

Machining

– CNC Machining: Machine mold components for high precision.

– Electrode Manufacturing: Produce electrodes for EDM when necessary.

-

Assembly

– Mold Assembly: Assemble machined components with precise alignment.

– Cooling Channel Integration: Install cooling channels for temperature regulation.

-

Testing and Validation

– First Article Inspection: Conduct a test run to produce initial samples and evaluate against specifications.

– Quality Control Checks: Perform checks to ensure mold meets standards.

-

Production

– Injection Molding: Use the validated mold for mass production of battery boxes.

– Cycle Time Optimization: Monitor the process for efficient production.

-

Post-Processing

– Finishing Operations: Apply trimming, polishing, or texturing as needed.

– Final Quality Assurance: Conduct a final inspection before delivery.

- Packaging and Delivery

– Packaging: Securely package finished products for transport.

– Logistics Coordination: Plan for timely delivery to customers.

Factory Show:

We maintain a robust array of facilities and equipment to guarantee top-tier production quality. Our mold-making operations are outfitted with cutting-edge machinery, including CNC machining centers, mirror EDM machines, traditional EDM units, slow-speed wire cut systems, and various auxiliary tools. Furthermore, our production lines incorporate 15 rubber compression machines and 2 liquid silicone rubber (LSR) injection molding machines. To uphold our stringent quality standards, we implement rigorous monitoring and testing protocols throughout the manufacturing process.