Design and Prototype Development

The initial phase of mould creation involves designing the mould. This design specifies the shape, size, and intricate details of the part to be produced. After finalizing the design, a prototype is developed. The prototype serves as a test model to ensure the mould can produce the intended part accurately. Once the prototype meets all standards and requirements, the mould manufacturing process begins.

intended part accurately. Once the prototype meets all standards and requirements, the mould manufacturing process begins.

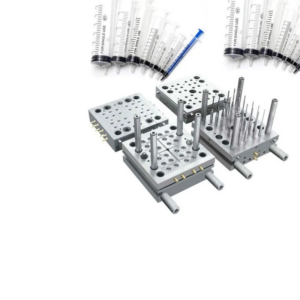

Mould Manufacturing Processes

Moulds can be created using various techniques, including casting, injection moulding, and extrusion. These methods involve the use of specialized machinery and tools. The mould is then used to produce the desired parts through a process that may involve drilling, lathing, and pressing. The manufactured parts undergo assembly and rigorous testing to ensure they meet the specified quality and performance standards.

Variety of Moulded Products

We also specialize in a wide range of related mould products, including:

- Soap Case on Shower Stand Moulds: Designed for creating durable and aesthetically pleasing soap cases.

- Sliding Cover Moulds: Ideal for manufacturing sliding covers with precise fitting and smooth operation.

- Friction Pad Moulds: Used to produce high-quality friction pads for various automotive applications.

- Fasten Nut Moulds: Essential for creating robust and reliable fastening nuts.

- Marbles Moulds: Used for the production of decorative and functional marbles.

- Non-Slip Mat Moulds: For manufacturing mats that provide excellent grip and safety.

- Decoration Ring Moulding: Perfect for creating decorative rings with intricate designs.

- Decoration Cover of Suspension Base Moulds: Specialized for making covers that enhance the look of suspension bases.

- Sprayer Body Injection Moulds: Used in the production of durable and efficient sprayer bodies.

Advanced Injection Molding Techniques

Our manufacturing facility specializes in advanced injection molding techniques, offering top-notch precision and efficiency. Utilizing S136 steel for the mold core and 45# steel for the mold base, our injection molding process ensures durability and reliability. With a single cavity design, our production capability reaches up to 50 sets per month, delivering consistent quality and performance with each run.