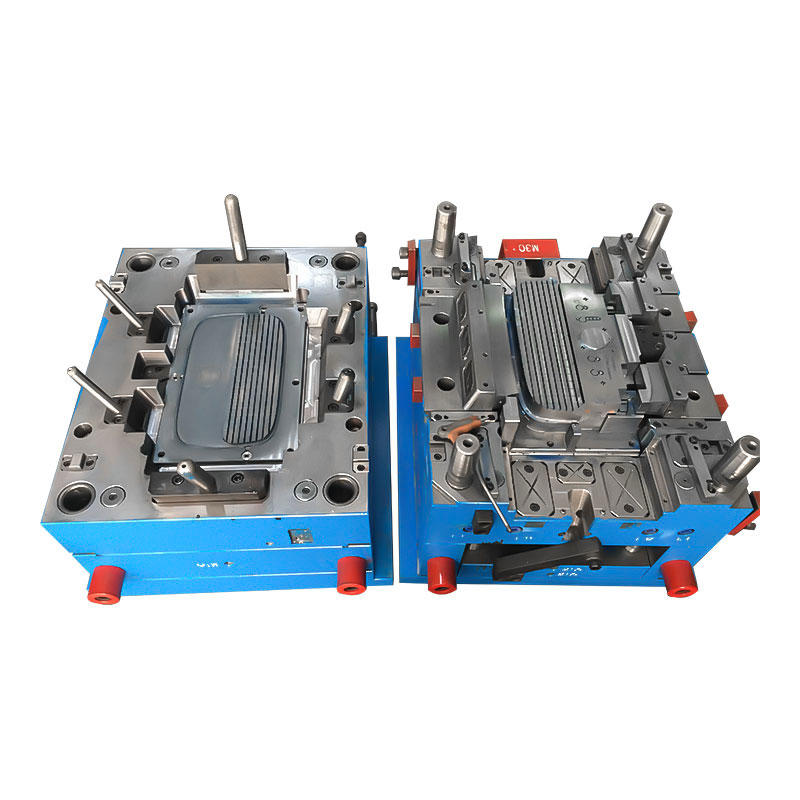

The Household Appliance Housing Mold is a specialized tool designed for the production of durable and precisely engineered plastic housings for various household appliances. Crafted from high-quality materials, this mold ensures consistent and accurate manufacturing of complex shapes and intricate details, meeting the exact specifications required for modern appliances.With a focus on longevity and efficiency, the mold is engineered to withstand high-volume production runs while maintaining excellent dimensional stability and surface finish. Whether for small kitchen gadgets or larger home devices, the Household Appliance Housing Mold offers superior quality, helping manufacturers produce aesthetically pleasing and reliable products.

Comprehensive Manufacturing Solutions:

From our advanced facility in Xiamen, China,we provide cutting-edge precision engineering technology and a comprehensive array of services for our esteemed clientele. Our offerings include:

1.Injection Molding Prototype Design

2.Rapid Prototyping

3.Mold Tool Design

4.Tool Fabrication

5.Injection Molding

6.Assembly and Secondary Processing

7.Ultrasonic Welding

8.Painting Services

9.Printing Services

Customization Service for Molds

– Design Consultation:Collaborate with clients to understand specific design requirements and preferences.

– Technical Drawings:Create detailed technical drawings and specifications based on client input.

– Material Selection:Assist in choosing appropriate materials for both the mold and the final product to ensure optimal performance.

– Tooling Development:Develop custom tooling and molds tailored to meet precise specifications and production needs.

– Prototype Production:Produce prototypes to validate design, functionality, and material choices before full-scale production.

– Mold Fabrication:Utilize advanced manufacturing techniques to create high-quality, durable molds.

– Surface Finishing:Apply various surface treatments, including polishing, coating, and texturing, to meet aesthetic and functional requirements.

– Testing and Validation:Conduct rigorous testing of molds to ensure they meet quality standards and performance expectations.

– Adjustments and Iterations: Make necessary adjustments and refinements based on prototype testing and client feedback.

– Production Support:Provide ongoing support throughout the production process, including troubleshooting and maintenance.

– Quality Assurance: Implement stringent quality control measures to ensure the molds meet industry standards and client specifications.

– Delivery and Installation:Manage logistics for timely delivery and offer installation support to ensure seamless integration into the production line.