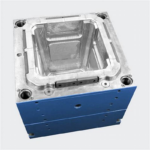

Overview:

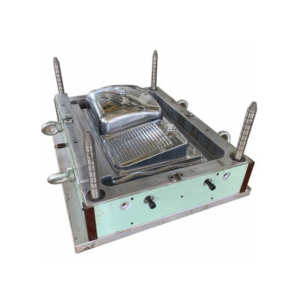

Overview:

Creating a high-quality kitchen sink is crucial, and its production process is inherently complex. Fortunately, our factory simplifies this process through extensive experience and expertise. With many years in sink manufacturing, our skilled technicians ensure rigorous quality control throughout production, even when dealing with large-scale molding projects.

Our molds are designed to be as durable as, if not more durable than, other types of molds, guaranteeing a long service life and reliable performance. In addition, we offer tailored customization services. We can design molds specifically for your product lines, aligning closely with your expectations for new products. This customization not only meets your precise design requirements but also enhances your production efficiency.

Characteristics:

| Shaping Mode | Plastic Injection Mold |

| Model Number | Household Kitchen Sink Molding |

| Runner Type | Cold/Hot Runner |

| Installation Type | Fixed |

| Certification | ISO |

| Customization | Available |

| Mold Life | 500,000 to 1,000,000 Shots |

| Transport Packaging | Wooden Box |

| Specification | Customization |

| Trademark | OEM |

| Place of Origin | Xiamen, China |

| Production Capacity | 50 Sets per Month |

| Plastic Material | ABS, PP, PC, PVC, POM, TPU, PC, PEEK, HOPE, NYLON, Silicone Rubber, etc. |

| Mold base | LKM, HASCO, DME, self-control etc. |

| Surface Finish | Polishing/smooth, Texture/frosted, Printing, Painting, Plating |

| Our Equipment | High speed CNC, standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic injection Molding Machine from 30-1400T available. |

| Main Fields | Security equipment, Intelligent instrument, Consumer electronics, Medical device, Home appliance, Automotive parts, Kitchen equipment, Robots, etc. |

Manufacturing Process:

- Design for Manufacturability (DFM) Report: Evaluate design feasibility.

- Mold Design: Create detailed CAD designs.

- Material Selection: Choose suitable construction materials.

- CNC Machining : Precisely cut mold components.

- Laser Cutting: Make precise, clean cuts.

- Wire Cutting: Cut intricate details precisely.

- Grinding: Refine and smooth surfaces.

- Assemble Mold: Assemble mold components accurately.

- Stamping: Add features and impressions.

- Sample Inspection: Verify mold design specifications.

- Mass Production: Produce molds in bulk.

- Cleaning: Remove manufacturing debris.

- Packing: Securely package molds.

- Delivery: Manage timely, secure transport.

- After-Sales Service: Provide ongoing support.

We ensure that every process is executed with perfection, attention to detail, and thorough inspection to guarantee the quality of your goods.