At LSRmold, we are committed to providing the highest quality and precision when it comes to medical plastic injection molding components. With over 10 years of experience in mold manufacturing, design, and injection molding, our team understands the complexities and stringent requirements of the medical industry. In this blog, we’ll share the key areas where accuracy can be enhanced in the production of medical molding components, from mold design to processing, and how LSRmold ensures top-notch results for every project.

-

The Importance of Precision in Mold Design

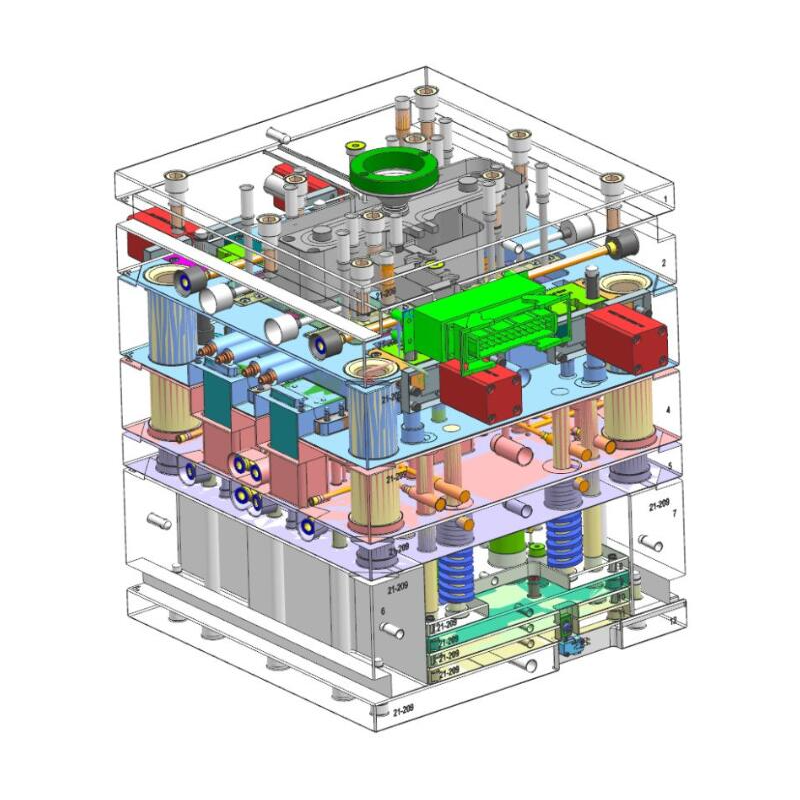

The foundation of accurate medical molding components begins with the mold design. At LSRmold, our experienced mold engineers have an extensive background in mold design and mold technology, ensuring that each mold meets the highest standards of precision. Here are some crucial aspects of mold design that contribute to the accuracy of medical components:

– Understanding of Plastic Materials: Our mold engineers possess in-depth knowledge of various types of plastics and their properties. This allows us to select the best material for each specific application, ensuring that the molded part performs well under medical-grade conditions.

– Familiarity with Manufacturing Processes: We ensure that our mold designs are optimized for the manufacturing processes. This guarantees smooth production and minimizes the risk of defects, ensuring the final product meets precise specifications.

– Advanced Design Skills: With strong skills in creating 3D models and analyzing designs for strength, durability, and efficiency, our engineers are able to design complex molds that deliver the highest level of accuracy and consistency.

– Expert Knowledge of Mold Materials: Selecting the right materials for the mold is essential for ensuring the accuracy and longevity of the mold. Our engineers understand the pros and cons of various mold materials and choose the most appropriate ones for each project.

– Problem-Solving Abilities: We pride ourselves on our ability to identify potential problems in the mold design early in the process and develop creative solutions to ensure the accuracy of the final product.

– Communication and Project Management Skills: Our team collaborates closely with engineers, production staff, and customers to ensure that the mold design aligns with the project’s goals. We also manage multiple projects simultaneously, meeting deadlines without compromising quality.

-

Mold Processing: The Key to High-Precision Results

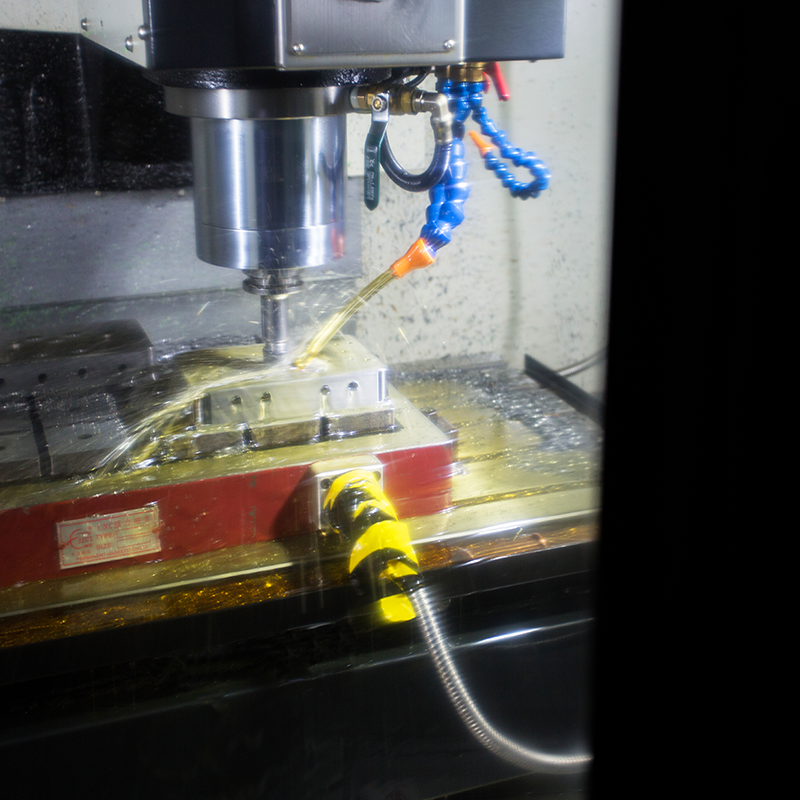

Once the mold design is finalized, it’s time for mold processing—the critical step in ensuring the precision of medical plastic injection molding components. At LSRmold, we use state-of-the-art equipment and techniques to guarantee that our molds are built to the highest standards of accuracy:

– High-Speed CNC Machines: In April 2022, LSRmold upgraded its equipment by acquiring four advanced CNC machines (NXV 600A) from Taiwan. These machines play a crucial role in machining the components of molds, such as cavities, cores, inserts, and mold base components, ensuring high precision.

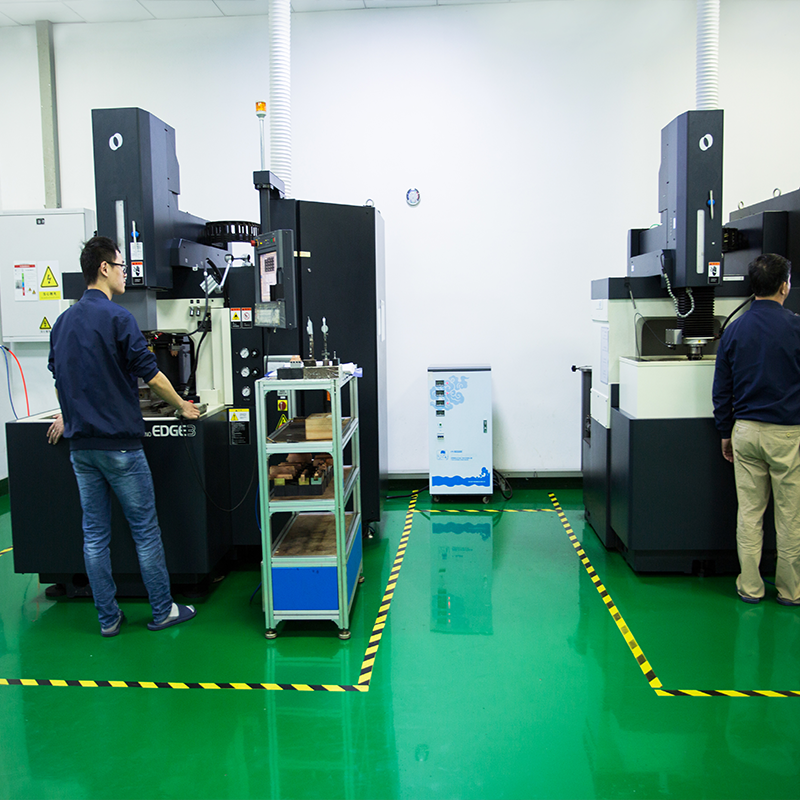

– Electrical Discharge Machining (EDM): EDM is a highly accurate technique used in mold manufacturing. LSRmold uses two high-performance DM1470M-CNCEDM machines to increase both the efficiency and precision of the mold-making process. We also use copper electrodes that are meticulously measured using Coordinate Measuring Machines (CMM). Only those electrodes that pass inspection are used in the manufacturing process.

– Wire Electrical Discharge Machining (WEDM): Our WEDM process, using low-speed wire machines, enhances the accuracy of mold components. This technique is particularly effective for machining inserts, ejector pin holes, lifter holes, and other intricate features of the mold.

– High-Quality Mold Bases: To ensure the final product meets the required accuracy, LSRmold uses high-quality mold bases from reputable brands. While this may incur higher costs, the investment guarantees mold precision and, ultimately, higher-quality medical components.

– Experienced Mold Makers: Mold-making is a specialized skill, and we are proud to have a team of highly experienced mold makers. Over 60% of our mold makers have more than 10 years of experience, giving them the expertise to handle complex and demanding mold structures. This experience is critical in minimizing risks and ensuring the mold runs smoothly during production.

– Measurement Precision: At LSRmold, we use CMM technology to measure all mold components with an accuracy of 0.01mm. This ensures that every component is within tolerance, helping to prevent errors and ensuring the mold delivers precise results.

-

Injection Molding Technology: Ensuring Consistent Accuracy

The injection molding process itself plays a significant role in the final accuracy of the medical components. At LSRmold, we invest heavily in the latest technology and employ experienced engineers to manage the injection molding process. Here’s how we achieve high accuracy in this crucial step:

– Modern Injection Molding Machines: In 2021, we expanded our capabilities by purchasing 20 new injection molding machines. These machines, combined with our skilled engineers, help us meet the unique demands of various industries, including medical molding. Our engineers have over 20 years of experience, enabling them to expertly control key factors like mold temperature, injection pressure, and cooling time to produce consistent, high-quality parts.

– Efficient Process Control: Our injection molding engineers are adept at matching raw materials to the appropriate molding process. This includes drying the material, controlling the mold temperature, and ensuring that the injection pressure is optimized for each part. These precise controls minimize defects such as sink marks, warping, and dimensional inconsistencies.

– Automated Production: Once the mold has been tested and fine-tuned, LSRmold employs automated systems, such as robots for picking up parts, to ensure consistent and efficient production. This also reduces the potential for human error and improves overall accuracy.

– Data-Driven Quality Control: After successful mold testing, our team records critical molding data and prepares quality control documents, including Standard Operating Procedures (SOP), Statistical Process Control (SPC), and other metrics. These documents are used for future mass production, ensuring that every batch of medical components meets the required quality standards.

-

Continuous Commitment to Quality and Innovation

At LSRmold, we don’t just meet industry standards—we aim to exceed them. We are dedicated to continuously improving our processes, expanding our knowledge, and investing in new technologies. This commitment ensures that we remain at the forefront of mold manufacturing, able to meet the ever-growing demands of the medical industry.

Our team stays up-to-date with the latest advancements in mold design, materials, and manufacturing techniques to maintain our competitive edge. We also regularly train our engineers and mold makers to ensure that they have the skills necessary to handle complex medical molding projects.

Contact Us for Your Medical Plastic Injection Molding Needs

We understand how crucial accuracy is in the medical industry, and at LSRmold, we are here to help you achieve the highest quality standards in your medical plastic injection molding components. If you have any questions or would like to discuss your next project, don’t hesitate to contact us. Our team is always ready to provide professional insights and work closely with you to meet your specific needs.Thank you for choosing LSRmold—where precision meets excellence.