If you are a corporate buyer or engineer tasked with sourcing complex plastic or metal components, managing custom part orders, or finding a reliable manufacturing partner for injection molding or CNC machining, the process might be more challenging than anticipated. The landscape of custom manufacturing is diverse, and selecting the right supplier can significantly impact the success of your projects. In this blog, we will delve into essential considerations and criteria for choosing a suitable injection molding or CNC machining company, ensuring that your sourcing decisions align with both current and future project demands.

The Importance of Establishing Long-Term Expectations

The journey to finding the right manufacturing partner should begin with a comprehensive understanding of your long-term business model and what you expect from your custom part supplier. It’s crucial to articulate your needs not only for the present projects but also for anticipated future demands. The specifics of each manufacturing project can vary widely, influencing sourcing decisions significantly.

Key considerations include production batch sizes, in-house manufacturing capabilities, and quality assurance processes. Not all injection molding and CNC machining companies offer the same production capabilities or adhere to the same quality standards. For instance, some suppliers may excel in high-volume production but lack the agility required for smaller runs. Others might offer comprehensive in-house manufacturing but have limited quality assurance measures. Establishing clear expectations can facilitate informed decision-making, ensuring a trouble-free product launch.

Criteria for Choosing the Right Custom Part Manufacturer

To identify the most suitable custom plastic injection molding or CNC machining supplier, you should consider several critical factors:

-

Industry-Specific Knowledge

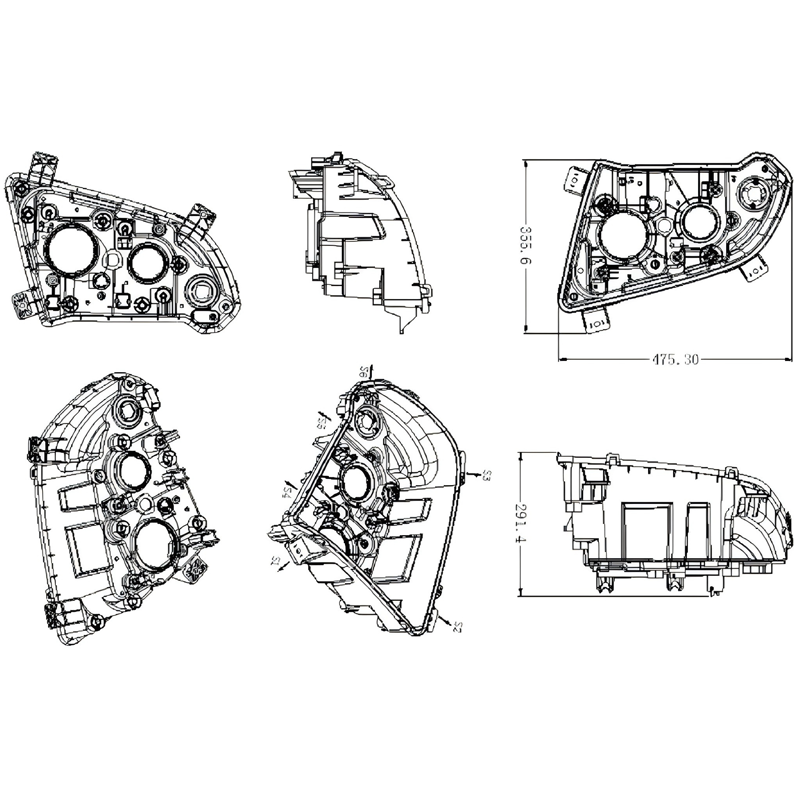

A supplier’s experience in your specific industry or niche is paramount. They should demonstrate a proven track record of producing the type of components you require and be well-versed in the unique demands of your sector. Each industry often has distinct supply chain expectations regarding quality, project management, payment terms, and regulatory compliance. A partner with industry-specific expertise can better anticipate challenges and deliver solutions tailored to your needs.

-

Technical Expertise

Technical prowess across all processing facets is essential for a successful manufacturing partnership. Whether you need injection molding or CNC machining, your supplier should address manufacturing feasibility concerns, tooling requirements, and any specialized processing needs dictated by the materials you choose. This expertise ensures that the parts produced meet your specifications and perform reliably in their intended applications.

-

Available Capacity

Monitoring manufacturing capacity is a vital metric for any reputable custom part manufacturer. A supplier with too much excess capacity might face financial challenges, resulting in inconsistent pricing and unreliable order fulfillment. Conversely, a company operating at full capacity may struggle to meet new order demands, leading to delays. Assessing a manufacturer’s available capacity is critical to ensure timely delivery and reliable performance.

-

Quality Assurance

Quality control is a non-negotiable aspect of any manufacturing partnership. Seek companies with rigorous quality assurance processes that ensure the production of high-quality parts. While ISO certifications are a valuable indicator of quality, it’s essential to inquire about the specific quality control procedures and in-house inspection methods employed by the manufacturer. A robust planning and quality assurance process is indicative of a reliable manufacturing partner.

-

In-House Capabilities

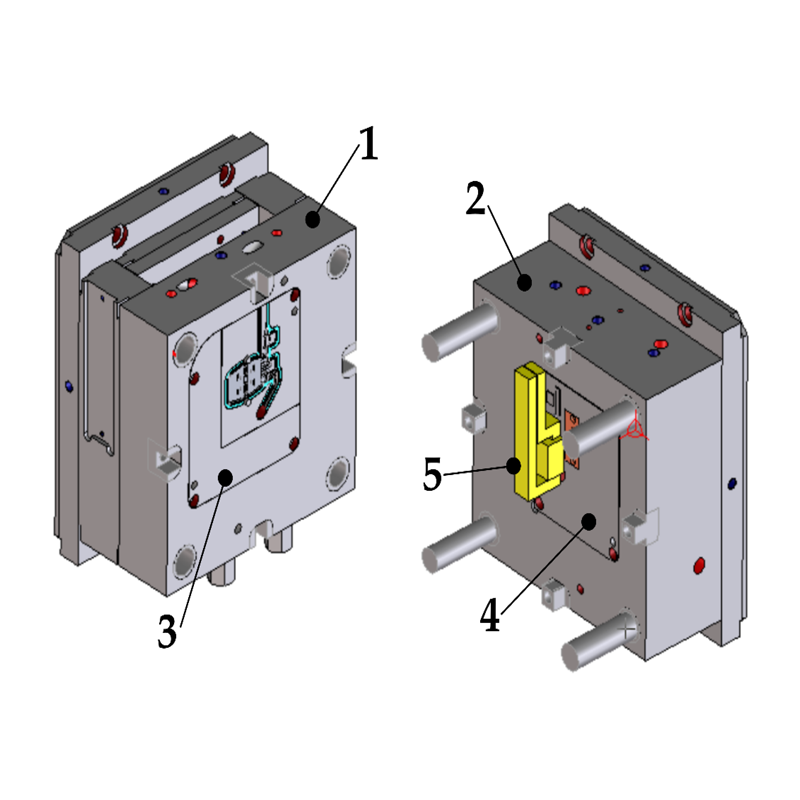

Ideally, your chosen company should offer a full suite of services without the need for outsourcing. For plastic injection molded parts, look for suppliers that provide in-house mold making. This integration ensures that the quality of your tooling and parts is consistent and managed under one roof. Additionally, the presence of modern machinery, equipment, and in-house Coordinate Measuring Machine (CMM) inspections can further bolster confidence in a manufacturer’s capabilities.

-

Relationship Building

Before finalizing any sourcing decision, take the time to develop a rapport with the team you’ll be working with. Custom manufacturing can present various challenges, and the differences between high-quality manufacturers and low-cost suppliers can be stark. A strong working relationship with your supplier can facilitate effective communication, quick problem resolution, and a smoother project flow.

Source Your Parts with LSRmold

With the right injection molding or CNC machining partner, you can enjoy reduced lead times and exceptional product quality. If you’re in search of a dependable custom part supplier, consider LSRmold. Established in 1998, we are a full-service manufacturer based in the United States, specializing in a wide range of capabilities. We can handle both low- and high-volume production orders, employing 6S lean manufacturing methods to minimize waste and enhance customer value.

Conclusion

In summary, selecting the most suitable injection molding or CNC machining supplier is a multifaceted process that requires careful consideration of various factors. By establishing clear long-term expectations, evaluating industry-specific knowledge, technical expertise, available capacity, quality assurance processes, and in-house capabilities, you can make informed decisions that align with your project requirements. At LSRmold, we are committed to providing high-quality manufacturing solutions tailored to meet the diverse needs of our clients. Reach out to us today to discuss how we can support your custom part manufacturing endeavors.