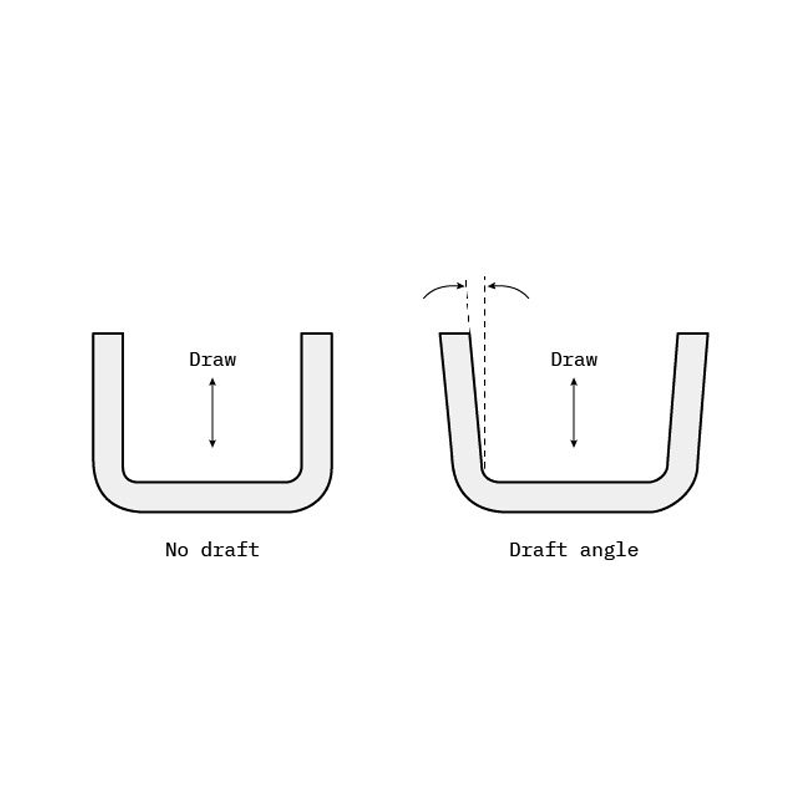

When designing injection-molded components, one detail consistently separates efficient, scalable production from costly manufacturing headaches: the draft angle. At LSRmold, we’ve supported thousands of injection-molding projects across consumer goods, automotive, medical, and industrial sectors. One pattern is unmistakable—designs with proper draft angles mold cleanly, run faster, and create far fewer complications. Designs without them? They […]