Medical Mold

Custom Plastic Parts Medical Injection Mold

Overview Plastic parts for medical injection molding are precision-engineered components designed for use in medical devices. Manufactured using high-quality plastic materials, these parts are created through an injection molding process, ensuring consistency, durability, and reliability. They meet strict industry standards for safety and performance, making them ideal for applications in healthcare, such as diagnostic equipment, […]

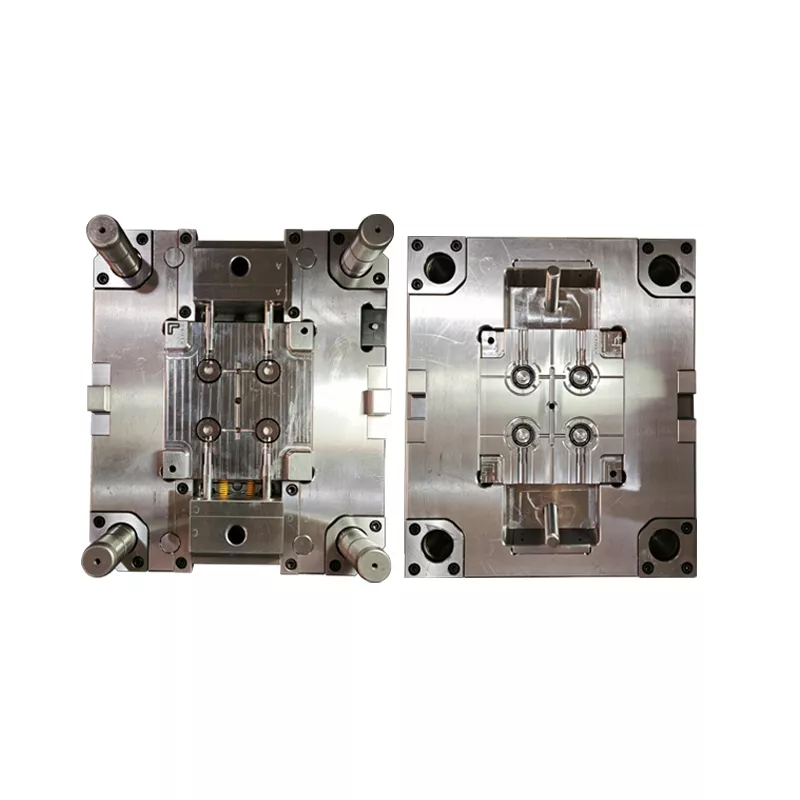

Read MorePlastic Injection Mold Medical Part Mold

Overview Plastic injection molds for medical parts are highly specialized tools designed to produce precision components used in the medical industry. These molds are engineered to create parts with tight tolerances, high durability, and biocompatibility, ensuring they meet strict regulatory standards. The injection molding process involves injecting molten plastic into a custom-designed mold cavity, which […]

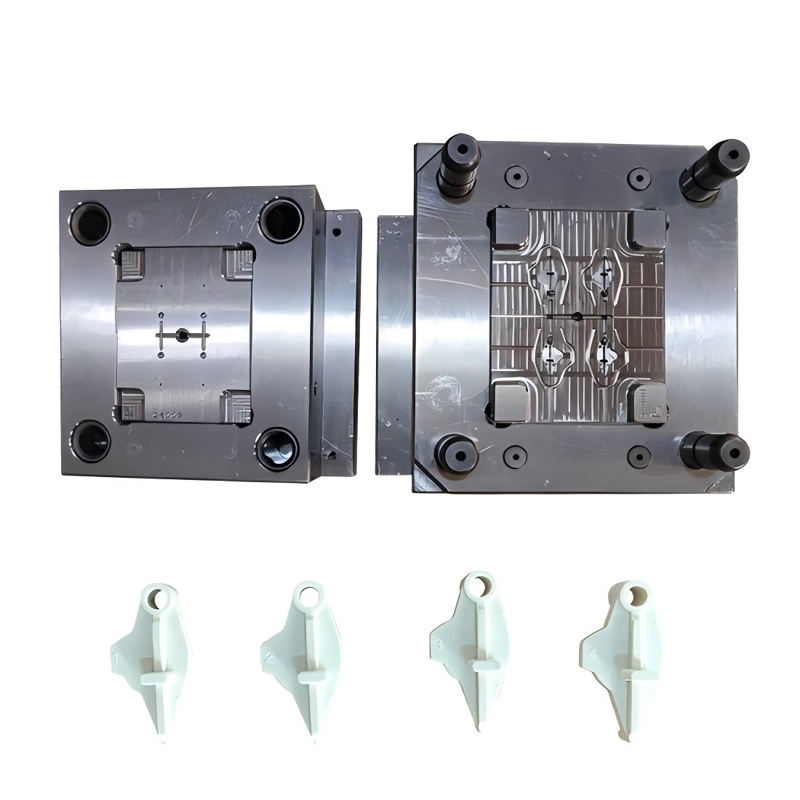

Read MorePlastic Injection Molding Mold for Medical Parts

Our plastic injection molding mold for medical components is engineered for precision and adheres to the highest quality and regulatory standards. Ideal for high-volume production, this mold offers cost-effective manufacturing solutions while accommodating a variety of medical-grade materials. At All-Plastics, we ensure each mold is tailored to meet the specific needs of our clients, guaranteeing […]

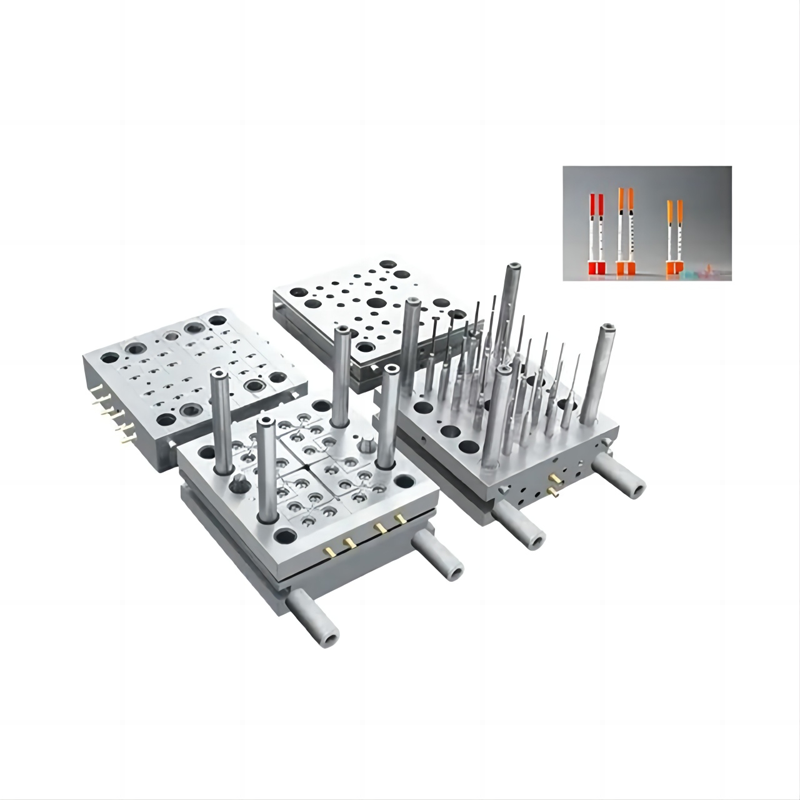

Read MoreFactory Medical Disposable Testing Tube 2K Injection Mold Core

Production Details Product name Medical Disposable Testing Tube 2K Injection Mold Core Mold shaping Plastic Injection molding, Mold base LKM;HASCO;DME,etc Mold material NAK20,S136,P20.718H,738H,45#,etc Mold cavity Single or Multi Tolerance +/-0.001mm Finish Anodized,Polish,Silk-screen,Painting,etc Sprue gate Hot/cold runner;pin-point gate,etc Design software UG,PROE,CAD,SOLIDWORK,etc Product material ABS,PP,PE,POM,PMMA,etc Mold life 100k-500k shots Lead time 25-45 days Transportation By sea, by air or by land as you request Package Standard or as you request OEM/ODM Acceptable Certificate ISO9001:2015,SGS,TS16949 Our Competitive Edge: – Premium Quality Standards – Competitive Pricing Structure – Timely Delivery […]

Read MoreChina Syringe Injection Molding Machine Medical Needle Hub Mould

Customer Service Standards: Pre-sale: – Thorough Confirmation:Discuss and confirm product types and quantities with customers to ensure accuracy. – Attentive Attention:Approach each inquiry with patience, seriousness, and attention to detail. – Lead Time Management:Efficiently arrange production and closely monitor lead times to meet customer expectations. – Careful Inspection:Conduct thorough inspections before delivery to ensure accuracy […]

Read MoreCustom Medical PP Plastic Syringe Barrel Injection Mould

Design and Prototype Development The initial phase of mould creation involves designing the mould. This design specifies the shape, size, and intricate details of the part to be produced. After finalizing the design, a prototype is developed. The prototype serves as a test model to ensure the mould can produce the intended part accurately. Once […]

Read More