Injection Molding Mold

Plastic Insert Mold

Our plastic insert molding molds are expertly crafted to address complex manufacturing challenges, delivering enhanced strength and durability by seamlessly integrating components. We offer tailored solutions with advanced techniques like multi-material molding and precise insert placement, ensuring a flawless bond and superior performance. Each mold is designed with meticulous precision and optimized for long-term durability. […]

Read MorePlastic 2-shot Molding Mold

Our expertly engineered 2-shot plastic molding molds are designed to deliver unparalleled quality and precision in multi-material molding processes. Also referred to as dual-shot, double-shot, or multi-shot molding, this technique combines two distinct plastic resins in a single production cycle, significantly enhancing efficiency and ensuring product integrity. This cutting-edge molding process is ideal for producing […]

Read MoreCustom Plastic Injection Molding Mold

Our precision-engineered plastic injection molding molds are designed to meet the specific requirements of each client. With advanced technical expertise, we produce molds that deliver superior performance, durability, and versatility across a wide range of industries. We are dedicated to offering customized solutions, ensuring every mold is manufactured with the highest level of precision and […]

Read MoreCustom Thermoset Tooling

Our expert craftsmen utilize high-speed mills to ensure the precise dimensional accuracy essential for Thermoset molding. With over 20 years of experience in Thermoset tooling, we consistently deliver flash-free tools that are production-ready. Our team possesses deep expertise in selecting specialty steel, determining optimal heater and sensor placement, and applying suitable coatings to enhance tool […]

Read MorePlastic Injection Mold for Auto Parts

Details: – Place of Origin:Xiamen, China – Service:OEM – Product Material:Steel – Shaping Mode:Plastic Injection Mould – Injection Material:ABS, PP, PS, PE, PVC, PA6, PA66, etc. – Mould Material:P20, 718, 738, NAK80, S136, 2738, 2316 – Mold Base:LKM, HASCO, DME, or Chinese Standard – Tolerance:0.003mm – 0.01mm – Drawing Format:STEP, STP, IGS, X-T, STL, CAD, […]

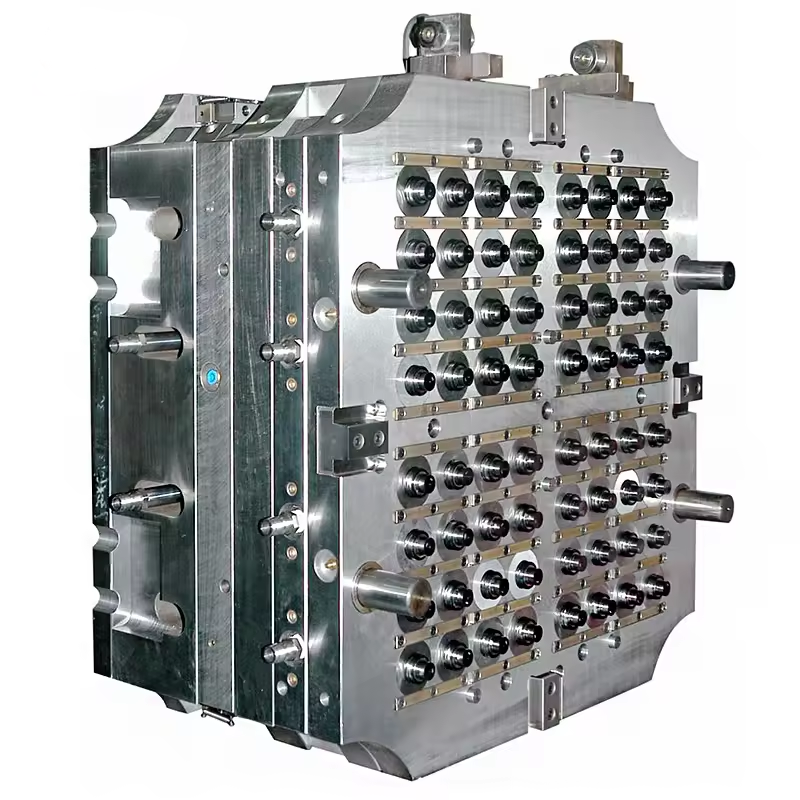

Read MoreFamily Injection Molds Manufacturer

Custom Plastic Injection Molding provides an excellent method for creating specialized plastic components. For clients seeking large-scale production or sets of related parts, using family molds or multi-cavity molds can lead to considerable savings in both time and cost. Family mold and multi-cavity injection molding are both effective techniques for producing multiple parts at once. […]

Read MoreCustom Plastic Injection Molding Mould

Precision Plastic Moulding Expertise With extensive experience in producing a wide range of precision plastic mouldings, we specialize in several key areas: – Insert & Outsert Mouldings: Expertise in manufacturing components such as plugs, moulded terminals, thumb nuts, and electrical connectors. – Intricate & Micro Precision Mouldings: Proficiency in creating highly detailed and extremely small […]

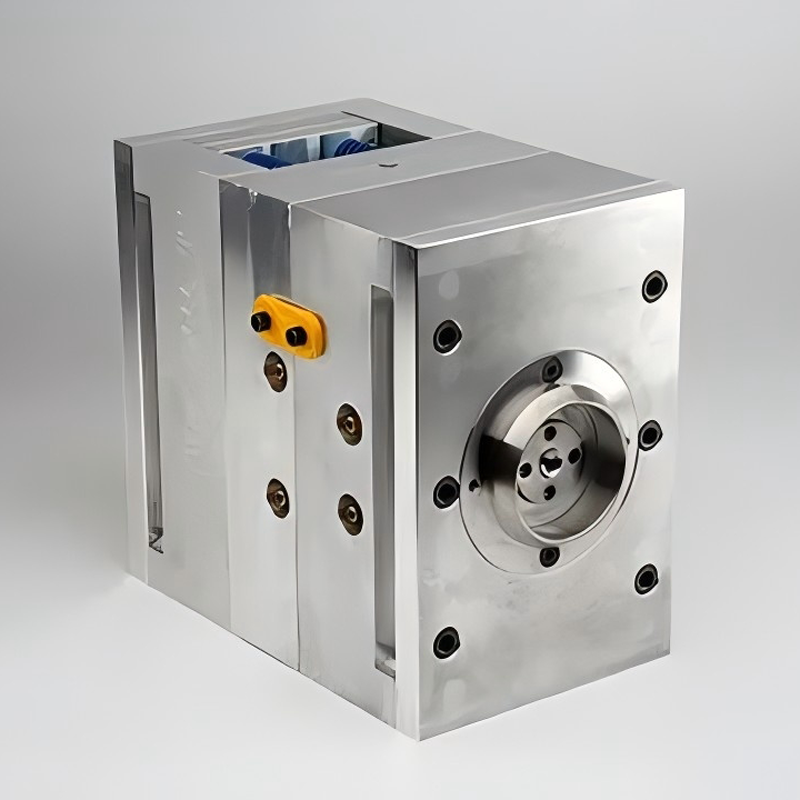

Read MoreCustom Blow Hdpe Bottle Mould For Injection Moulding

Advanced Injection Molding Techniques Our manufacturing facility specializes in advanced injection molding techniques, offering top-notch precision and efficiency. Utilizing S136 steel for the mold core and 45# steel for the mold base, our injection molding process ensures durability and reliability. With a single cavity design, our production capability reaches up to 50 sets per month, […]

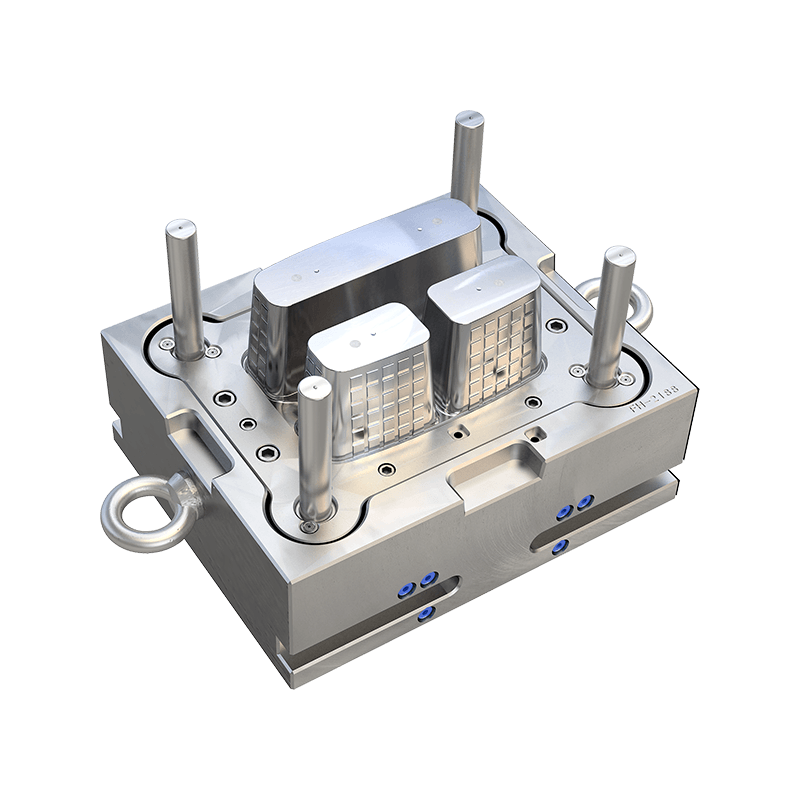

Read MoreCustom Plastic Housing Products Injection Mold For Dustbin

Advanced Manufacturing Techniques Our plastic housing molds are created using sophisticated plastic injection technology. This ensures high precision and durability in every product we supply. Comprehensive Plastic Mold Design Process Designing a plastic mold involves multiple critical stages to ensure the final product meets all specifications and quality standards. Here’s an overview of our detailed process: […]

Read MoreCustom Plastic Molding Injection Hot Steel PVC Surface Software Design Mould

Mold Packaging & Shipping: Antirust coating applied to core and cavity surfaces. Butter coating applied to mold surfaces. Mold wrapped in plastic membrane. Mold placed into wooden case. Spare parts and all data sheets (2D/3D drawings and revised drawings) included. Wear parts such as springs, ejector pins, cooling connectors, eye bolts will be packed together […]

Read More- « Previous

- 1

- 2

- 3

- 4

- Next »