Injection molding has become a cornerstone of modern manufacturing, enabling the production of everything from intricate components no larger than a fingernail to large-scale automotive parts. Its ability to create high-quality plastic components efficiently at scale is unmatched. However, as demand for injection molded products grows across industries, cost control remains a crucial factor. Whether you’re in need of large-volume production or smaller batch runs, selecting the right country for your mold manufacturing can be as important as the product design itself. For businesses looking to balance quality and cost, the choice of manufacturing location is a critical decision.

At Lsrmold, we specialize in providing reliable and cost-effective injection molding services. In this article, we’ll dive into the factors that influence the cost of injection mold-making services across various countries and compare the advantages and challenges of outsourcing to regions like China, India, Mexico, and Southeast Asia.

Key Factors Affecting Injection Mold Manufacturing Costs

Several factors play a role in determining the overall cost of injection molding services. These include:

1. Material Costs

The type of materials used for both molds and plastic resins significantly impacts the cost. While high production volumes can allow manufacturers to negotiate discounts on raw materials, the specific choice of metal for molds and plastic materials plays a pivotal role in determining overall manufacturing expenses.

2. Machine Power and Efficiency

The cost per unit tends to decrease as production volumes increase. This is because optimized processes, better energy efficiency, and shorter production times allow manufacturers to lower overall production costs. Manufacturers who embrace automation and advanced technologies can further enhance efficiency.

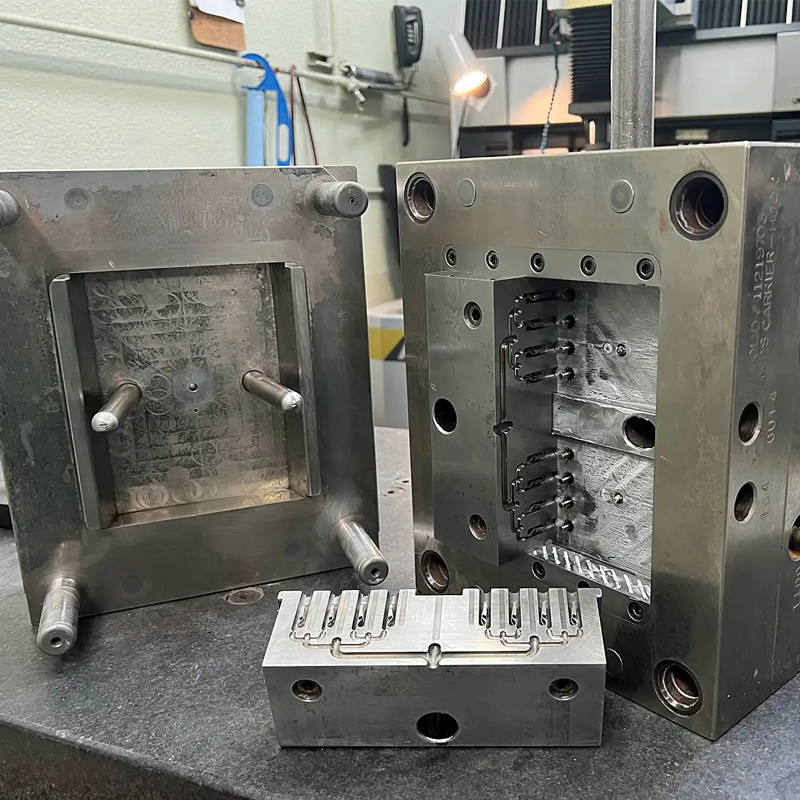

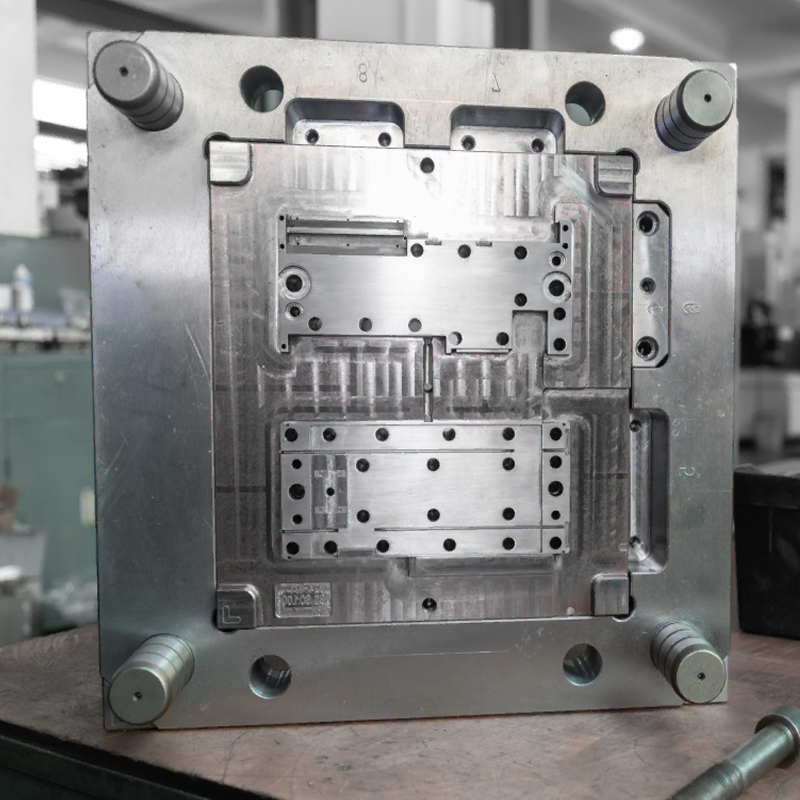

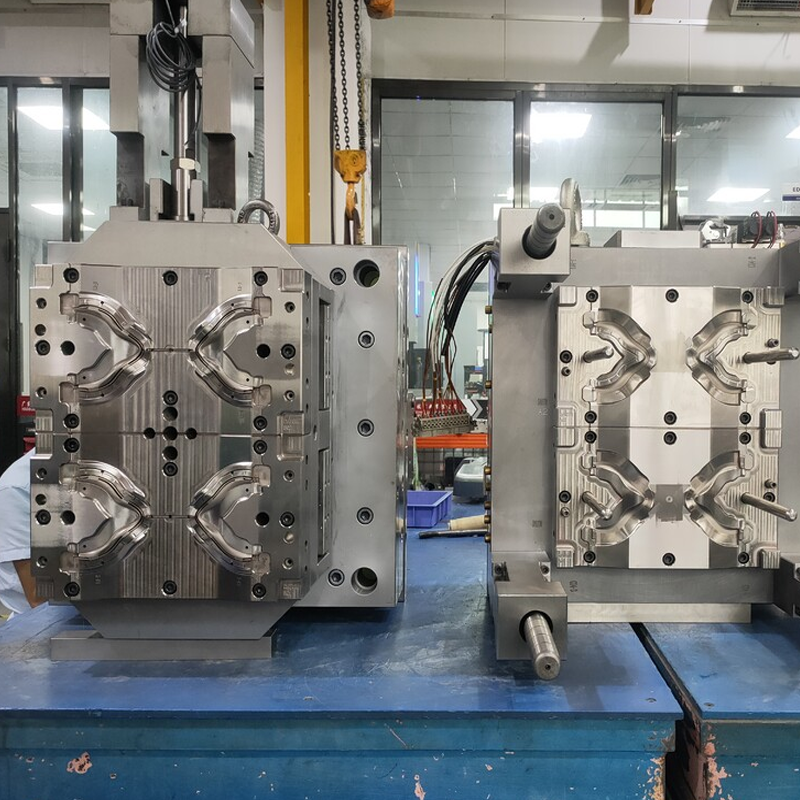

3. Mold Design and Complexity

The more complex the design, the higher the manufacturing cost. Intricate molds require more materials, advanced tooling, and labor. The complexity of the design can thus cause prices to vary widely, even for the same material.

4. Labor Costs

Labor is one of the largest cost components in mold-making. While labor costs tend to vary significantly by region, countries with lower wage rates can offer a substantial cost advantage. This factor often makes or breaks the decision when considering global manufacturing options.

5. Manufacturing Location

Geography influences more than just labor costs. Proximity to suppliers, transportation expenses, and market accessibility all affect the final cost of injection molding services. For instance, North American companies might find Mexico to be a more cost-effective option than other regions due to its proximity.

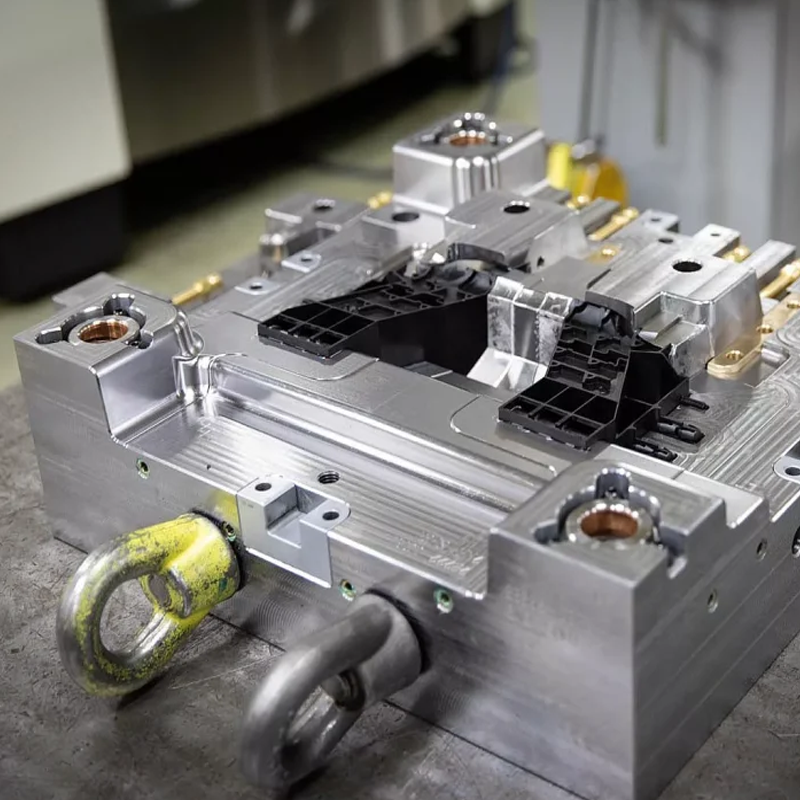

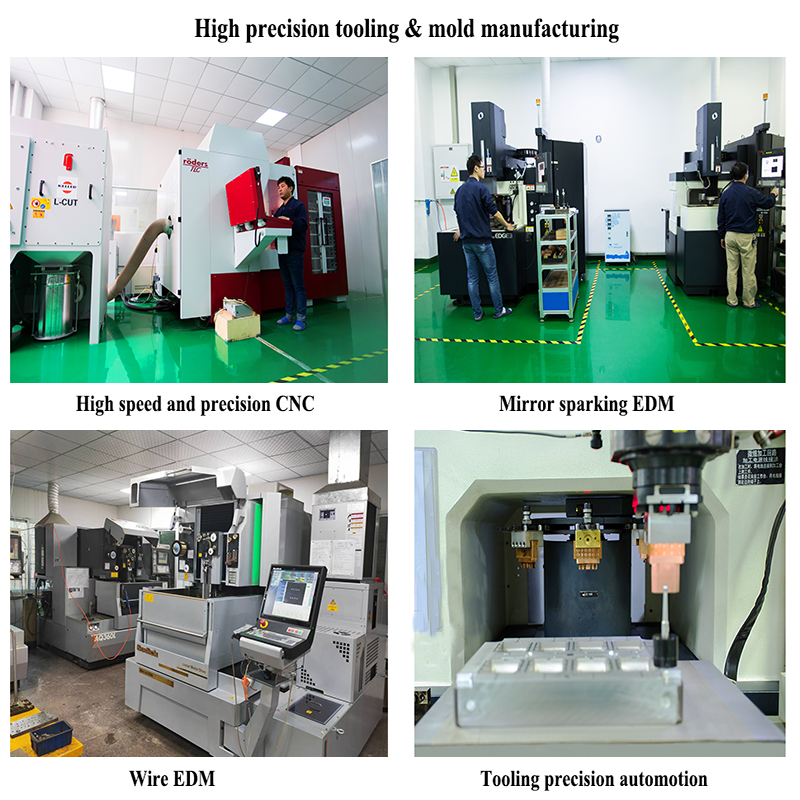

6. Technology and Equipment

Countries with advanced manufacturing technologies can produce high-quality molds more efficiently. The level of automation, precision, and the availability of specialized equipment directly impact the speed and accuracy of the mold-making process, ultimately affecting costs.

Leading Countries for Affordable Injection Mold-Making Services

Several countries have emerged as leaders in providing cost-effective and reliable injection mold-making services. These regions offer competitive pricing without compromising on quality, making them ideal destinations for businesses looking to scale production. Here’s a closer look at some of the top choices:

1. China

China has long been a global leader in injection molding, offering unmatched production capacity and cost-efficiency. The country’s rapid industrialization and technological advancements have bolstered its reputation as the go-to destination for mass production. However, as labor costs rise, the price advantage has narrowed. Despite this, China remains an attractive option due to its ability to handle large-scale production efficiently and cost-effectively.

Advantages:

- Unmatched Scale:With over 580,000 mold-making factories, China can handle massive production runs.

- Competitive Pricing:Even with rising costs, China offers competitive prices, especially for large orders.

- Quality Assurance:As China’s manufacturing capabilities improve, so too does its quality control, ensuring reliable products.

Challenges:

- Language and Cultural Barriers:Communication can be challenging for businesses unfamiliar with Chinese language and culture.

- Intellectual Property (IP) Risks:Protecting proprietary designs can be difficult in a foreign market, though NDAs can mitigate this risk.

2. Mexico

Mexico has emerged as a key player in the injection molding industry, particularly for businesses based in North America. Its proximity to the U.S. and Canada offers significant cost advantages, particularly when considering transportation and logistics. As labor costs in China continue to rise, Mexico has become an increasingly attractive option for manufacturers looking for a more cost-effective, geographically close alternative.

Advantages:

- Labor and Transport Savings:Wages in Mexico are competitive, and proximity to North American markets reduces transportation costs.

- Shorter Lead Times:Mexico’s proximity means faster turnaround times compared to Asian suppliers.

- Duty-Free Access:Mexico’s free trade agreements with major global economies, including the USMCA, make it easier and cheaper to trade.

Challenges:

- Capacity Limitations:While Mexico has strong manufacturing capabilities, it doesn’t have the sheer scale of China.

- Quality Standards:Although improving, some manufacturers may not meet the same quality standards found in other regions, especially in high-tech industries.

3. India

India’s lower labor costs, favorable exchange rates, and increasing investment in manufacturing technologies make it an appealing option for injection molding services. Furthermore, the government’s “Make in India” initiative has further incentivized local production.

Advantages:

- Low Labor Costs:India offers some of the most affordable labor rates globally.

- Favorable Policies:Government initiatives like SEZs (Special Economic Zones) encourage investment and make it easier to set up manufacturing operations.

- Technological Advancements:Emerging technologies, such as 3D printing, are reducing costs and enhancing capabilities.

Challenges:

- Infrastructure Limitations:In some areas, India’s infrastructure may not be as developed as other manufacturing hubs, leading to potential delays or logistical challenges.

- Quality Concerns:While quality is improving, there may be a learning curve for new manufacturers.

4. Southeast Asia (Vietnam, Thailand, Indonesia)

Countries in Southeast Asia, particularly Vietnam, Thailand, and Indonesia, are quickly becoming preferred destinations for cost-effective injection molding. These countries benefit from a strong labor force and favorable trade agreements, including the ASEAN Free Trade Area (AFTA).

Advantages:

- Strategic Location:Proximity to China, along with regional trade agreements, makes Southeast Asia an attractive option for businesses looking for competitive pricing.

- Skilled Workforce:Countries like Vietnam and Thailand have a skilled labor force, with a growing focus on quality manufacturing.

- Expanding Manufacturing Capacity:These countries are rapidly expanding their manufacturing capabilities, offering a reliable alternative to China.

Challenges:

- Quality Control Variability:While improving, the quality of production can vary depending on the specific region and factory.

- Infrastructure:Some countries may have infrastructure challenges, particularly in transportation and logistics.

Conclusion

Choosing the best location for your injection mold-making services requires evaluating several factors, from labor and material costs to logistics and technological capabilities. At Lsrmold, we understand the importance of balancing cost and quality when selecting a manufacturing partner. Whether you are considering China, Mexico, India, or Southeast Asia, each region offers distinct advantages. Ultimately, the right choice will depend on your specific needs, including production scale, delivery timelines, and budget constraints.

By carefully assessing these factors and aligning them with your project requirements, you can make an informed decision that supports your business’s long-term goals. Please feel free to contact us at Lsrmold for further insights on how we can help you optimize your injection molding processes, ensuring both cost efficiency and top-notch product quality.