The automotive industry continues to thrive as one of the most dynamic and in-demand sectors globally. Whether you’re driving a car, riding a bike, or boarding a bus, the products of this industry are an integral part of daily life. With this ever-growing demand for vehicles, manufacturers are under constant pressure to produce high-quality parts more efficiently and cost-effectively. This demand has led to the widespread adoption of injection molding—a manufacturing process that is revolutionizing the production of both interior and exterior automotive components.

At LSRmold, we specialize in advanced injection molding technologies designed to meet the stringent requirements of the automotive industry. Let’s explore how these technologies are shaping the future of automotive manufacturing.

What Are Automotive Interior and Exterior Components?

An automobile is a combination of numerous components, broadly categorized into interior and exterior parts. These components not only define the vehicle’s aesthetic appeal but also play a crucial role in its functionality, safety, and durability.

Automotive Interior

Interior parts are located within the vehicle, shaping its inner design and enhancing the user experience. Examples include:

- Dashboards

- Glove compartments

- Car seats

- Rearview mirrors

- Central consoles

These components demand precision engineering to ensure comfort, functionality, and aesthetic appeal.

Automotive Exterior

Exterior components form the outer body of the vehicle, protecting internal systems and defining the car’s style. Common examples include:

- Bumpers

- Side mirrors

- Hoods

- Trunk lids

- Tires

For both categories, manufacturers often rely on materials like plastics, metals, and composites to ensure durability and lightweight construction. Injection molding is a preferred method for creating these parts due to its versatility, efficiency, and ability to produce complex shapes.

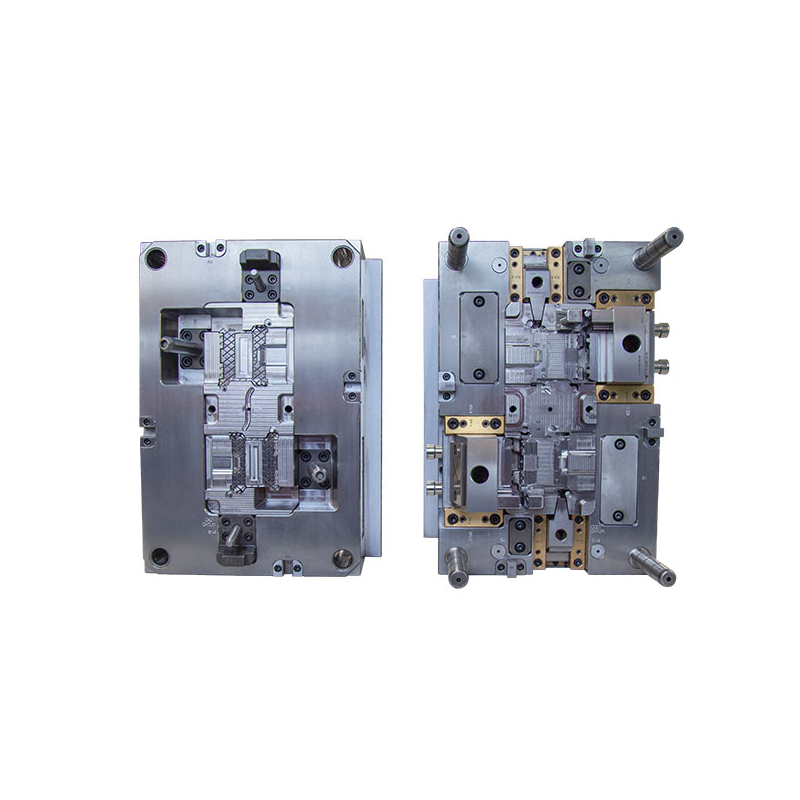

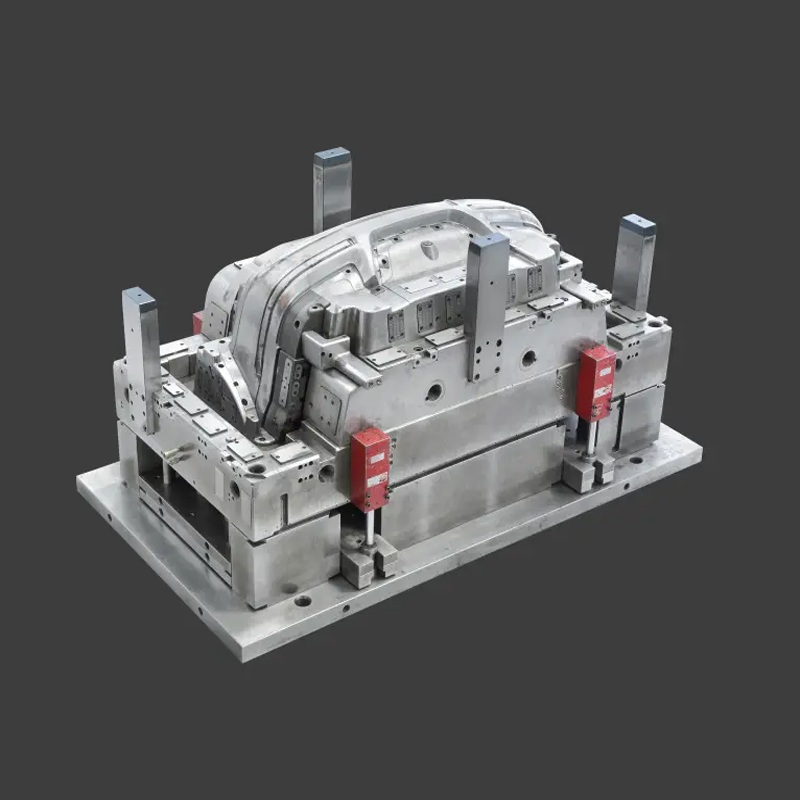

The Role of Injection Molding in Automotive Manufacturing

Injection molding is a highly efficient production process that involves injecting molten material into a mold cavity to create parts with intricate designs. While traditionally associated with plastics, injection molding is now used across various industries, including automotive, due to its ability to deliver high-quality results at scale.

For automotive interior and exterior parts, injection molding offers unparalleled benefits:

- Precision:Ensures accurate dimensions and flawless finishes.

- Cost-efficiency:Enables mass production at reduced costs.

- Material versatility:Compatible with a wide range of materials, including high-strength thermoplastics.

Advanced Injection Molding Technologies for Automotive Parts

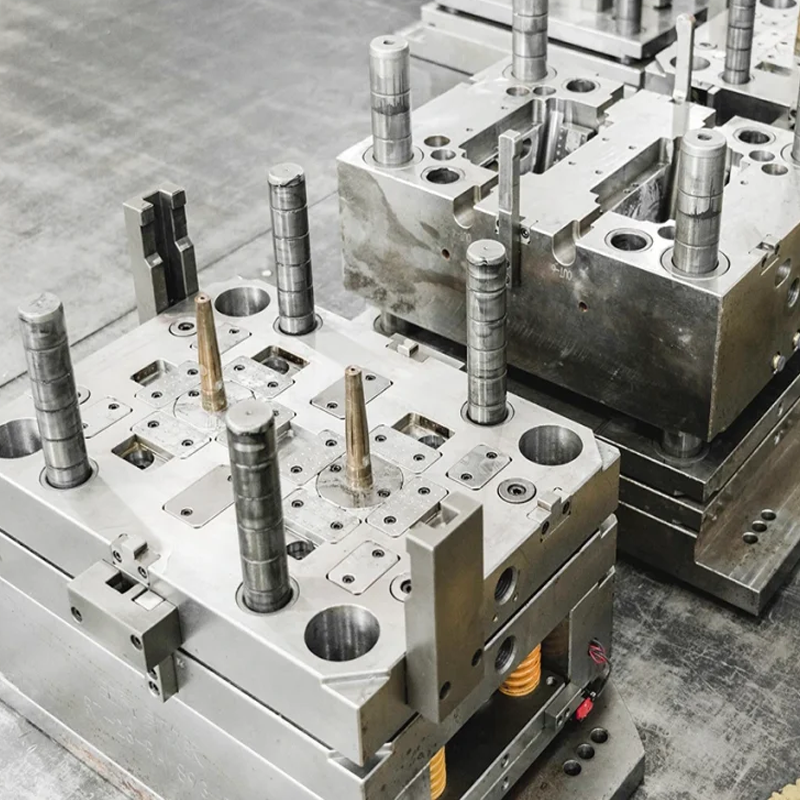

To meet the evolving demands of the automotive sector, advanced injection molding technologies have been developed. At LSRmold, we employ cutting-edge methods to enhance the quality, efficiency, and aesthetics of automotive components.

1. Sequence Valve Hot Runner Control Technology (SVG)

Sequence Valve Hot Runner Control Technology, or SVG, is a state-of-the-art cascade-type hot runner system. This technology ensures precise control over the injection process, reducing common defects such as weld lines and shrink marks.

- Improved Aesthetics:SVG technology eliminates unsightly appearance flaws, ensuring smooth and flawless surfaces for both interior and exterior parts.

- Enhanced Efficiency:By optimizing the flow length and reducing molding pressure, SVG improves production efficiency while maintaining product integrity.

- Applications:Ideal for intricate trim components, such as dashboards and door panels, where visual and structural perfection is critical.

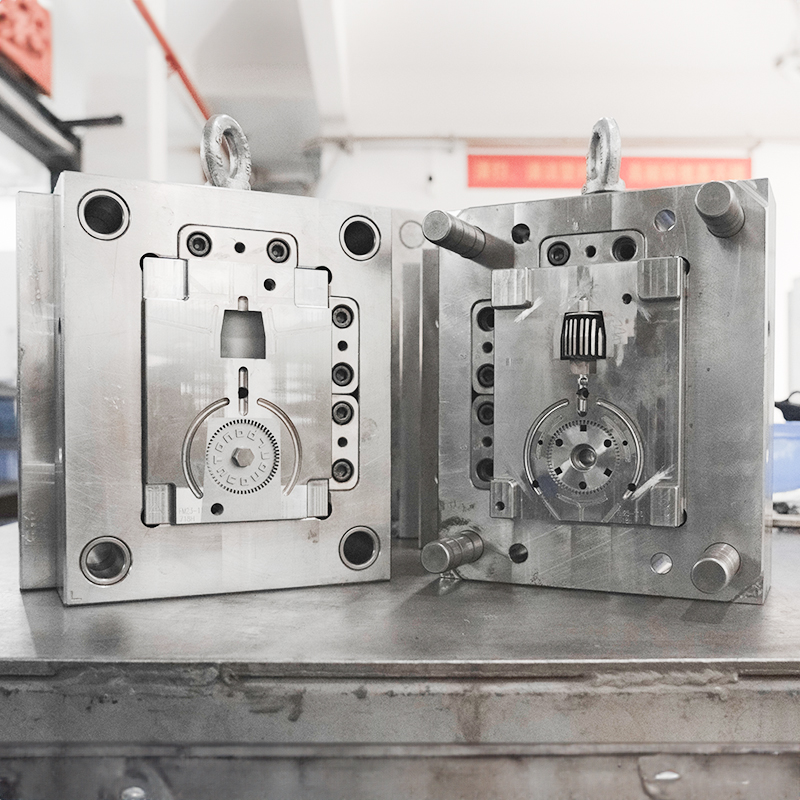

2. Low-Pressure Double-Layer Injection Mold Technology

Low-pressure double-layer injection molding is another breakthrough technology that combines precision with aesthetics. This method involves a lower injection pressure, which allows for the integration of a soft cloth layer into the mold.

- Superior Aesthetics:The added soft cloth layer enhances the tactile feel and appearance of interior components like car seats and central consoles.

- Durability:This method improves the longevity of parts while maintaining their decorative appeal.

- Applications:Commonly used for interior trim elements that require a sleek, sophisticated look.

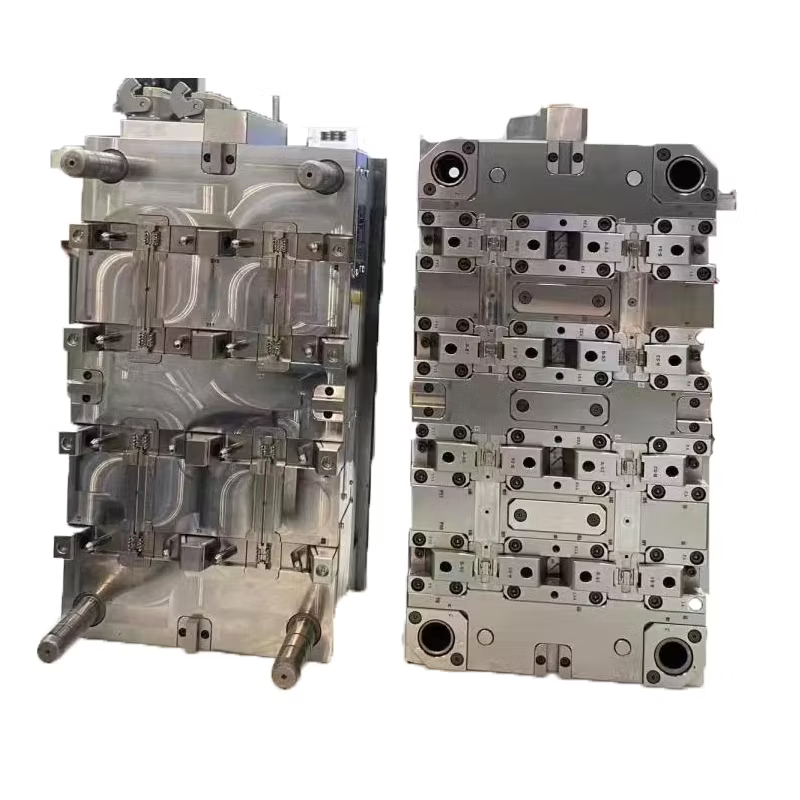

3. Car Bumper Internal Parting Injection Mold Technology

This advanced technology is specifically designed for manufacturing complex bumper components. Unlike traditional external parting methods, internal parting injection molding provides superior results:

- Hidden Seams:Internal parting conceals the parting lines, ensuring a seamless and visually appealing finish.

- Structural Integrity:The process supports intricate designs while maintaining the strength of the part.

- Applications:Widely used for high-end vehicles, where aesthetics and performance are paramount.

Why Choose LSRmold for Automotive Injection Molding?

At LSRmold, we understand the unique challenges faced by the automotive industry. Our expertise in advanced injection molding technologies enables us to deliver high-quality solutions tailored to your needs. Here’s why we are the preferred partner for automotive manufacturers:

- State-of-the-Art Facilities:Equipped with the latest machinery and tools for precision manufacturing.

- Skilled Expertise:A team of professionals dedicated to ensuring every product meets the highest standards.

- Custom Solutions:Tailored injection molding services to meet your specific design and functional requirements.

- Quality Assurance:ISO9001-certified processes that ensure consistency and reliability in every part we produce.

Let’s Collaborate!

The automotive industry is advancing rapidly, and staying ahead requires innovative manufacturing solutions. Whether you’re looking to enhance the aesthetics of interior components or improve the durability of exterior parts, LSRmold has the expertise to bring your vision to life.

Ready to elevate your automotive parts production? Contact us today to learn more about our advanced injection molding technologies. Let’s create something extraordinary together!