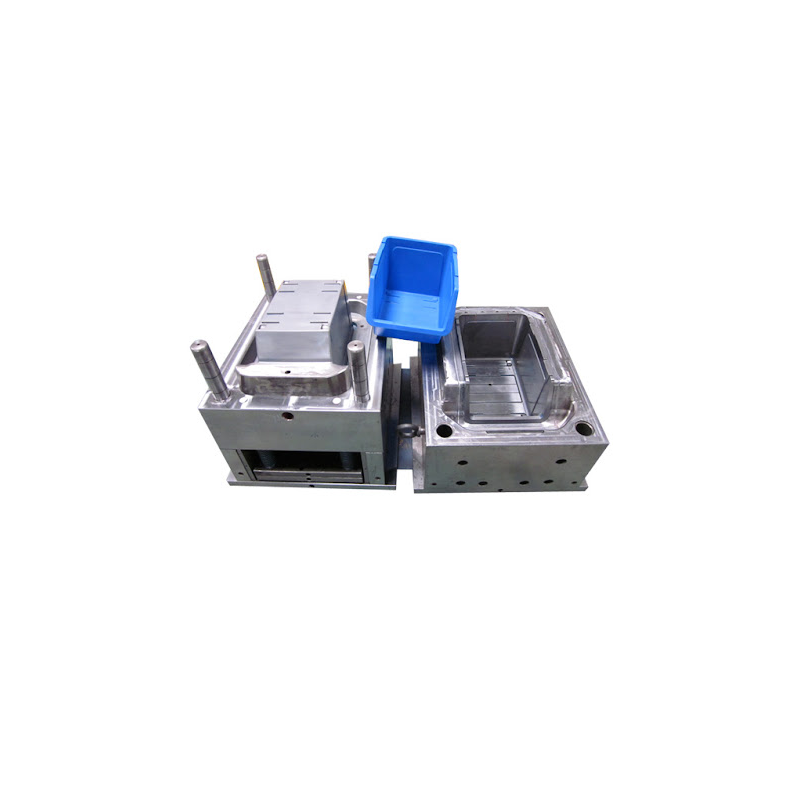

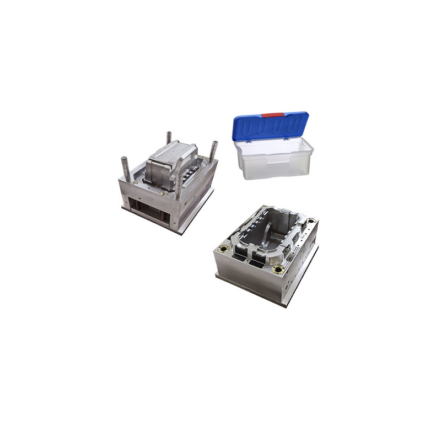

Tool box mould is a custom-designed mold used to manufacture durable and functional tool boxes, typically made from plastic or other sturdy materials. This mould is engineered to shape and form the tool box into its desired size and design, ensuring precise dimensions, smooth finishes, and strong structural integrity. Tool box moulds are widely used in industries such as automotive, hardware, and home improvement, where high-quality, rugged storage solutions are essential. Made from durable steel or aluminum, these molds are designed for long-lasting use and efficient mass production, providing consistent results and reducing manufacturing costs. A well-designed tool box mould ensures that the final product meets both aesthetic and functional requirements, offering practical storage with reliable performance.

Customization Service for Molds

– Design Consultation:Collaborate with clients to understand specific design requirements and preferences.

– Technical Drawings:Create detailed technical drawings and specifications based on client input.

– Material Selection:Assist in choosing appropriate materials for both the mold and the final product to ensure optimal performance.

– Tooling Development:Develop custom tooling and molds tailored to meet precise specifications and production needs.

– Prototype Production:Produce prototypes to validate design, functionality, and material choices before full-scale production.

– Mold Fabrication:Utilize advanced manufacturing techniques to create high-quality, durable molds.

– Surface Finishing:Apply various surface treatments, including polishing, coating, and texturing, to meet aesthetic and functional requirements.

– Testing and Validation:Conduct rigorous testing of molds to ensure they meet quality standards and performance expectations.

– Adjustments and Iterations: Make necessary adjustments and refinements based on prototype testing and client feedback.

– Production Support:Provide ongoing support throughout the production process, including troubleshooting and maintenance.

– Quality Assurance: Implement stringent quality control measures to ensure the molds meet industry standards and client specifications.

– Delivery and Installation:Manage logistics for timely delivery and offer installation support to ensure seamless integration into the production line.

Surface Treatment

- Polishing:

This process refines the mold’s surface finish, reducing friction and improving both appearance and performance. A well-polished mold leads to high-quality, defect-free products with superior surface smoothness.

- Texturing:

Texturing involves applying intricate patterns or designs to the mold surface. It’s ideal for creating unique finishes on the final product, such as leather-like textures or fine grooves, enhancing both functionality and visual appeal.

- Hard Chrome Plating:

Hard chrome plating enhances the hardness and wear resistance of the mold. It’s particularly effective for molds subjected to high friction, ensuring prolonged tool life and consistent product quality.

- Nitriding:

Nitriding diffuses nitrogen into the steel surface of the mold, forming a hard, wear-resistant layer. This treatment is essential for molds used in high-stress applications, enhancing their durability and performance.

- Titanium Nitride (TiN) Coating:

TiN coating provides a gold-colored, hard surface that enhances wear resistance, reduces friction, and improves mold release properties, making it ideal for high-volume production runs.

- Nickel Plating:

Nickel plating offers excellent corrosion resistance, protecting the mold from chemical or environmental exposure, particularly useful for molds operating in harsh conditions.

- Electroless Nickel Plating:

This uniform coating provides enhanced hardness, wear resistance, and corrosion protection without the need for an electric current. It ensures long-lasting mold performance, even in challenging environments.

- Anodizing:

Commonly used for aluminum molds, anodizing provides a durable, corrosion-resistant surface, allowing for color customization and enhanced aesthetic quality for easy identification.

- Black Oxide Coating:

Black oxide coating improves the mold’s corrosion resistance and appearance by creating a uniform black finish. It also reduces light reflection, beneficial for certain production environments.

- PVD (Physical Vapor Deposition) Coating:

PVD applies thin, durable layers of materials such as titanium, chromium, or zirconium to the mold surface, significantly increasing wear resistance, reducing friction, and improving mold longevity.

- Matt Finish:

A matt finish reduces surface gloss, creating a non-reflective surface ideal for products requiring a subdued, textured look. This finish can enhance the overall appearance and tactile quality of the molded part.

- VDI (Verein Deutscher Ingenieure) Textures:

VDI textures are standardized surface finishes commonly used in plastic injection molding. These textures range from fine to coarse and are essential for creating desired finishes on the final product.

- SPI (Society of the Plastics Industry) Finishes:

SPI surface finishes are industry-standard grades for plastic injection molds, ranging from mirror-like finishes to rough textures. Each grade offers distinct advantages based on the application and product requirements.

- Ball Burnishing:

Ball burnishing is a surface treatment that involves the mechanical smoothing of the mold surface through the application of steel balls under pressure. This process increases the surface hardness, enhances corrosion resistance, and provides a highly polished, defect-free finish.