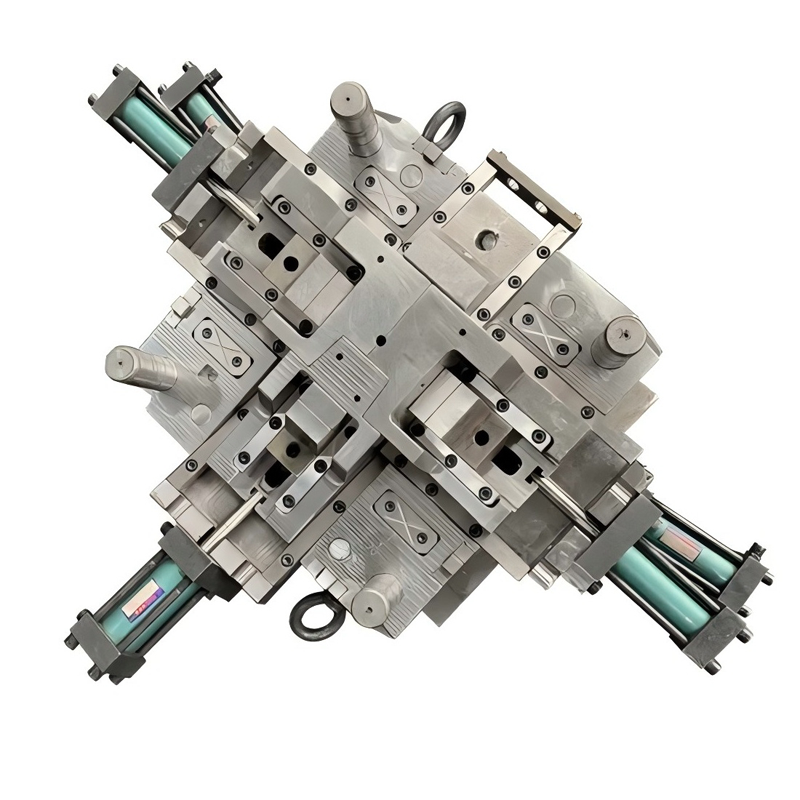

Our innovative plastic insert molding solutions for battery equipment and new energy applications are engineered for precision and reliability. Designed to meet strict customization demands, our advanced molds facilitate high-volume production while offering rapid prototyping capabilities. Ideal for creating durable, high-performance components for cutting-edge battery technologies , these molds ensure efficient, scalable manufacturing. Whether you need tailored prototypes or large production runs, our plastic insert molding technology delivers exceptional quality, flexibility, and performance to meet the evolving needs of the energy sector.

Basic Information

Mold Type: Plastic Injection Mold

Mold Material Options:P20, 718, 738, NAK80, S136

Mold Base Standards: HASCO, DME, MISUMI, JIS, LKM, etc.

Mold Runner System:Cold Runner / Hot Runner

Mold Gate Options:Slide Gate, Sub Gate, Pin-point Gate

Cavity:Single or Multi-Cavity

Design Software Supported:UG, PROE, CAD, SOLIDWORKS

Molding Equipment Used:CNC, Wire Cutting, Milling Machine, EDM

Compatible Raw Materials:ABS, PP, PC, PA6, PA66, PVC, POM, PMMA, PS, etc.

Packaging Method:Wooden pallet or carton

OEM Services:Available—please provide 2D/3D files or samples

Lead Time:Approximately 30 days

Advantages of Our Mold

- Superior Quality:

– Our molds are manufactured using high-grade materials and state-of-the-art techniques, ensuring exceptional durability, precision, and longevity. Each mold undergoes rigorous quality control checks to meet stringent industry standards.

- Customization:

– We offer highly customizable mold designs tailored to meet specific client requirements. Our team works closely with clients to develop molds that align perfectly with their unique production needs and specifications.

- Advanced Technology:

– Utilizing the latest in CNC machining, laser cutting, and precision engineering, our molds are crafted with unparalleled accuracy. Our advanced technology ensures consistent, high-quality output and reduces production downtime.

- Rapid Prototyping:

– We provide quick turnaround times for prototypes, allowing clients to test and validate their designs swiftly. This accelerates the product development process and brings products to market faster.

- Cost-Effective Solutions:

– By optimizing our production processes and utilizing efficient manufacturing techniques, we offer cost-effective mold solutions without compromising on quality. Our competitive pricing ensures value for money for our clients.

- Eco-Friendly Materials:

– We prioritize the use of eco-friendly materials and sustainable manufacturing practices. Our commitment to environmental responsibility ensures that our molds have a minimal impact on the environment.