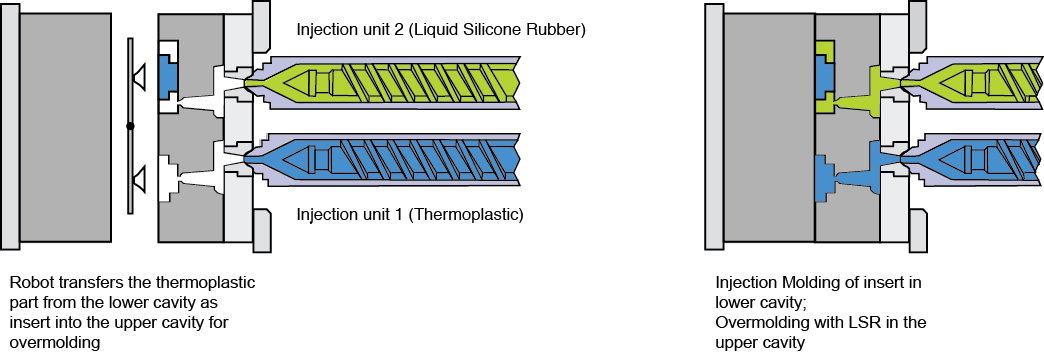

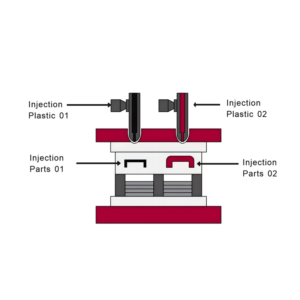

Our expertly engineered 2-shot plastic molding molds are designed to deliver unparalleled quality and precision in multi-material molding processes. Also referred to as dual-shot, double-shot, or multi-shot molding, this technique combines two distinct plastic resins in a single production cycle, significantly enhancing efficiency and ensuring product integrity. This cutting-edge molding process is ideal for producing intricate parts that feature different textures, colors, or materials. Committed to providing tailored solutions, we meticulously craft each mold to meet the highest standards of quality, durability, and performance. From the initial design phase through to final production, our focus is on maximizing efficiency and reliability while ensuring timely delivery and competitive pricing.

Basic Information

Place of Origin:Xiamen, China

Product Material: Steel

Plastic Material :PP, PC, PA, PA6, ABS, PET, PVC, POM, etc.

Gate System :Cold Runner / Hot Runner

Ejection System: Pin / Stripper Plate, etc.

A.B Plate Material: 1.1730 / P20, etc.

Tool Life: Prototype to 1,000,000 shots

Cavity & Core Material :P20 / H13 / NAK80 / S50C / S136 / 738H, etc.

Surface Finish :Polish / Texture / Heat Treatment, etc.

Cavities: Single / Multiple / Family Mold

Lead Time: 3 to 8 weeks

Advantages of Our Mold

- Superior Quality:

– Our molds are manufactured using high-grade materials and state-of-the-art techniques, ensuring exceptional durability, precision, and longevity. Each mold undergoes rigorous quality control checks to meet stringent industry standards.

- Customization:

– We offer highly customizable mold designs tailored to meet specific client requirements. Our team works closely with clients to develop molds that align perfectly with their unique production needs and specifications.

- Advanced Technology:

– Utilizing the latest in CNC machining, laser cutting, and precision engineering, our molds are crafted with unparalleled accuracy. Our advanced technology ensures consistent, high-quality output and reduces production downtime.

- Rapid Prototyping:

– We provide quick turnaround times for prototypes, allowing clients to test and validate their designs swiftly. This accelerates the product development process and brings products to market faster.