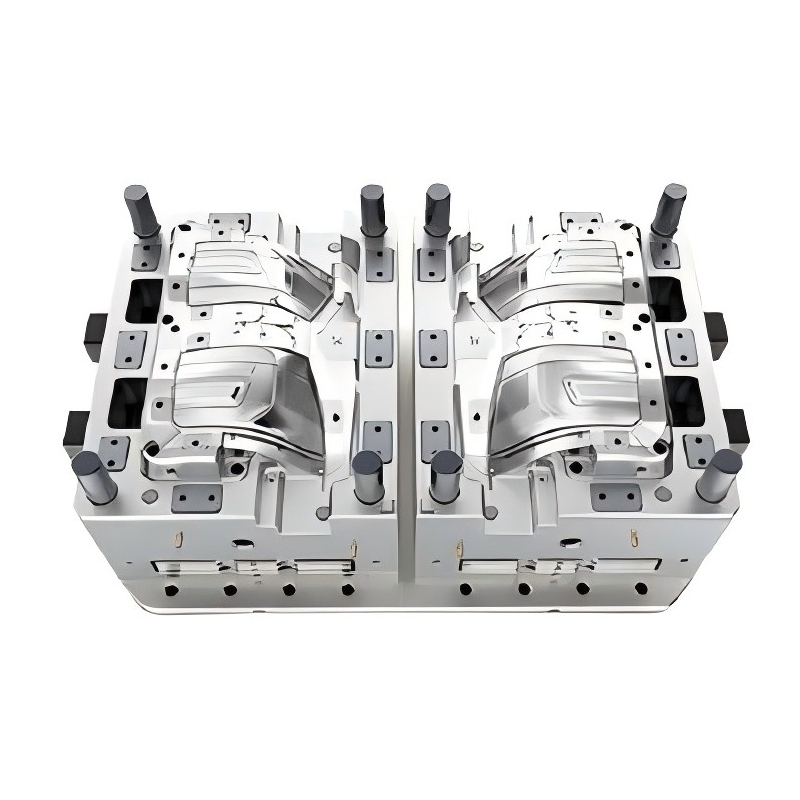

Customization and Capacity

The number of cavities in a mould can be customized based on the customer’s production requirements, ensuring optimal production capacity and efficiency. We provide high-quality moulds tailored to meet the specific needs of our clients, ensuring consistent and reliable performance in the manufacturing of automotive parts.

Our expertise in manufacturing high-precision moulds for plastic car parts and various other products ensures that we deliver solutions that meet the highest standards of quality and performance. Contact us to learn more about our offerings and how we can assist in your manufacturing needs.

Production Timeline

Our standard production timeline for plastic molds is 35-45 days, following a meticulous process to ensure quality and accuracy:

- Sample Submission: Customers provide samples.

- 3D Design: Our designers create a 3D model and send it for customer approval.

- Mold Design: Begin designing the mold.

- Material Procurement: Order the necessary steel.

- CNC Processing: Precision CNC machining.

- Electrosparking: Fine detail work on the mold.

- Mold Assembly: Assembling the completed mold.

- Testing: Conducting test injections.

- Sample Delivery: Sending plastic part samples to clients.

- Packing and Delivery: Final packaging and shipment.

- Customer Feedback: Collecting feedback for continuous improvement.

- New Orders: Process new orders based on feedback and demand.

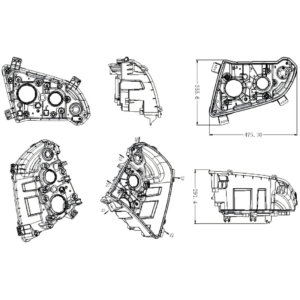

Design and Assembly Services

We provide complete design and assembly services to bring your concepts to reality. Whether you supply samples or 3D models, our expert team is equipped to turn your vision into a finished product. From the initial design phase to final assembly, our end-to-end services ensure a seamless experience.

With extensive experience and diverse capabilities, our factory is the perfect partner for automotive plastic parts injection molding. We are dedicated to delivering high-quality molds and plastic components tailored to your specifications. Reach out to us today to discuss your custom requirements and discover how we can support your production needs.