Production Details

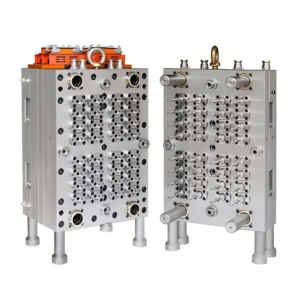

| Product name | Medical Disposable Testing Tube 2K Injection Mold Core |

| Mold shaping | Plastic Injection molding, |

| Mold base | LKM;HASCO;DME,etc |

| Mold material | NAK20,S136,P20.718H,738H,45#,etc |

| Mold cavity | Single or Multi |

| Tolerance | +/-0.001mm |

| Finish | Anodized,Polish,Silk-screen,Painting,etc |

| Sprue gate | Hot/cold runner;pin-point gate,etc |

| Design software | UG,PROE,CAD,SOLIDWORK,etc |

| Product material | ABS,PP,PE,POM,PMMA,etc |

| Mold life | 100k-500k shots |

| Lead time | 25-45 days |

| Transportation | By sea, by air or by land as you request |

| Package | Standard or as you request |

| OEM/ODM | Acceptable |

| Certificate | ISO9001:2015,SGS,TS16949 |

Our Competitive Edge:

– Premium Quality Standards

– Competitive Pricing Structure

– Timely Delivery Commitment

– Exceptional Post-Sale Support

– Stringent Quality Assurance

– Automation Implemented Across All Moulds

Comprehensive Plastic Mold Design Process

Designing a plastic mold involves multiple critical stages to ensure the final product meets all specifications and quality standards. Here’s an overview of our detailed process:

1.Initial Product Design

- Understanding Requirements: We start by thoroughly understanding the dimensions, shape, and functionality requirements of the plastic part to be molded.

- Specification Analysis: This involves a detailed analysis of the part’s specifications to guide the subsequent stages of mold design.

2.Structuring the Mold

- Mold Type Selection: Depending on the product’s requirements, we select the appropriate mold type—whether it’s a two-plate, three-plate, or hot runner mold.

- Design Elements: Key elements such as the parting line, gating system, and ejection system are meticulously designed to ensure smooth operation.

3.Cavity and Core Creation

- Draft Angles and Tolerances: Draft angles are incorporated, and surface finishes are specified to ensure easy ejection of parts.

- Precision Engineering: Tolerances are carefully controlled to facilitate proper plastic flow and product consistency.

4.Runner and Gate System

- Efficient Flow Design: The runner system is designed to deliver molten plastic efficiently from the injection machine to the mold cavity.

- Gate Placement: Gate location and size are optimized to control the plastic flow into the mold accurately.

5.Cooling System Integration

- Temperature Control: Cooling channels or inserts are integrated to manage the temperature and solidification of the plastic.

- Cycle Time Minimization: The cooling system is designed to ensure uniform cooling, reducing cycle times and improving productivity.

6.Venting and Air Management

- Proper Venting: Adequate venting is incorporated to allow air and gases to escape during injection.

- Air Trap Prevention: Air traps are strategically designed to prevent air from being trapped within the mold cavity.

7.Material Selection for Molds

- Choosing the Right Material: Mold materials are selected based on the type of plastic being molded, production volume, and cost-effectiveness. Common choices include high-grade steel and aluminum.

8.Manufacturing Considerations

- Machining and EDM: The manufacturing process includes precise machining and electrical discharge machining (EDM) to achieve the desired mold features.

- Polishing and Finishing: Final polishing ensures the mold meets the required surface finish and dimensional accuracy.

9.Testing and Validation

- Prototype Testing: Once the mold is completed, it undergoes rigorous testing to ensure it produces parts that meet all specifications.

- Adjustments: Any necessary adjustments are made based on the test results to perfect the mold design.