OEM Services for Molds

– Custom Design: Develop bespoke designs based on client specifications, including detailed technical drawings and 3D models.

– Material Selection: Assist clients in choosing the right materials for both the mold and the end product to ensure durability and performance.

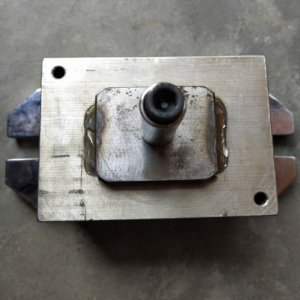

– Tooling Development: Design and manufacture custom tooling and molds tailored to specific production needs and technical requirements.

– Prototype Creation: Produce prototypes for client review to verify design accuracy and functionality before proceeding with mass production.

– Precision Machining: Utilize advanced machining techniques, including CNC and EDM, to create high-precision molds.

– Surface Treatment: Apply various surface finishes, such as polishing, coating, and texturing, to meet aesthetic and functional specifications.

– Testing and Validation: Conduct thorough testing of molds to ensure they meet performance standards and client requirements.

– Iterative Refinements: Make necessary adjustments based on testing results and client feedback to optimize mold performance.

– Production Support: Provide ongoing support throughout the production process, including troubleshooting and adjustments.

– Quality Assurance: Implement rigorous quality control procedures to ensure all molds meet industry standards and client specifications.

– Logistics and Delivery: Manage the delivery process to ensure timely and secure shipment of molds to client facilities.

– After-Sales Support: Offer comprehensive after-sales support, including maintenance and modifications, to ensure continued satisfaction and performance.

Machine Overview:

–EDM (Electrical Discharge Machining):Utilized for precision shaping and machining of materials using electrical discharges.

-Band Saw Machine:Employed for cutting various materials with accuracy and efficiency.

-Lathe Machine:Used for shaping and machining cylindrical workpieces with precision.

-Milling Machine:Ideal for precise shaping and cutting of solid materials using rotary cutters.

-3D Printer:Enables the production of three-dimensional objects layer by layer using additive manufacturing techniques.

-Grinding Machine:Utilized for grinding and polishing materials to achieve precise dimensions and surface finishes.

-CNC Lathe Drilling Machine:Combines lathe and drilling capabilities with computer numerical control for high-precision machining operations.

Our Dedicated Team:

Our team consists of highly skilled professionals with deep expertise in injection mold tooling, design, and automation. We emphasize ongoing skill enhancement and knowledge growth to provide the best solutions for our clients, employing the latest manufacturing techniques.