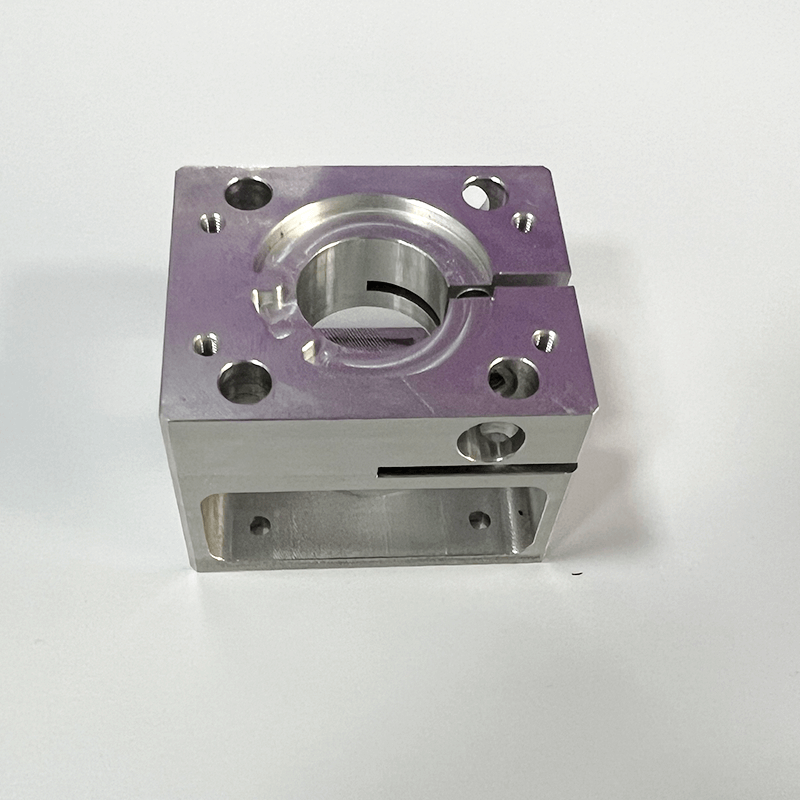

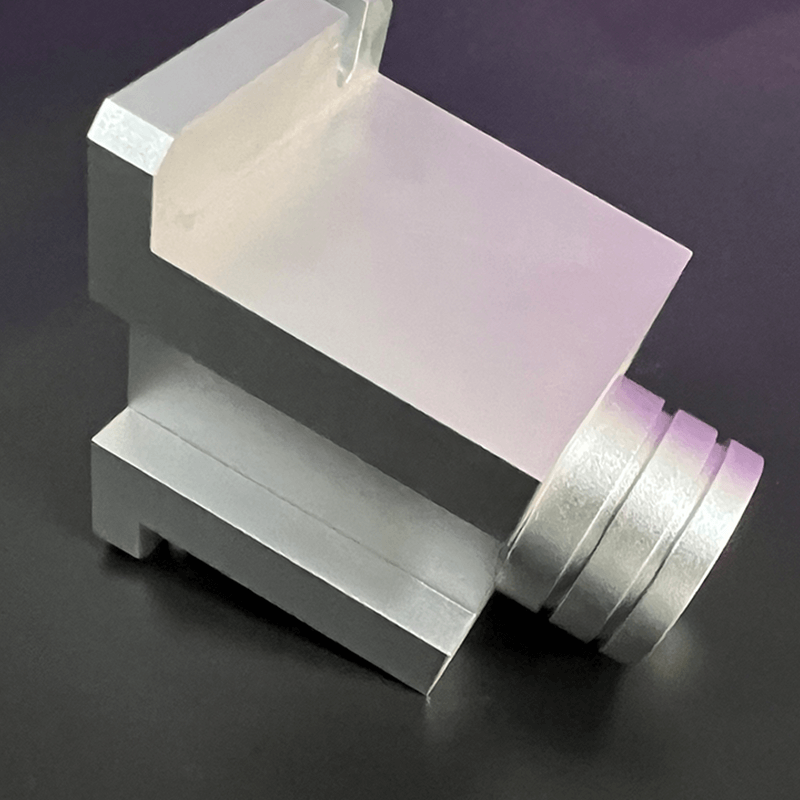

CNC Milling

Reliable on-demand CNC milling services for rapid prototypes and production parts.

Obtain top-quality custom milled components from a variety of high-grade metals and plastics at competitive prices.

Lsrmold provides cost-effective milling solutions for single parts, prototype batches, or full production orders.

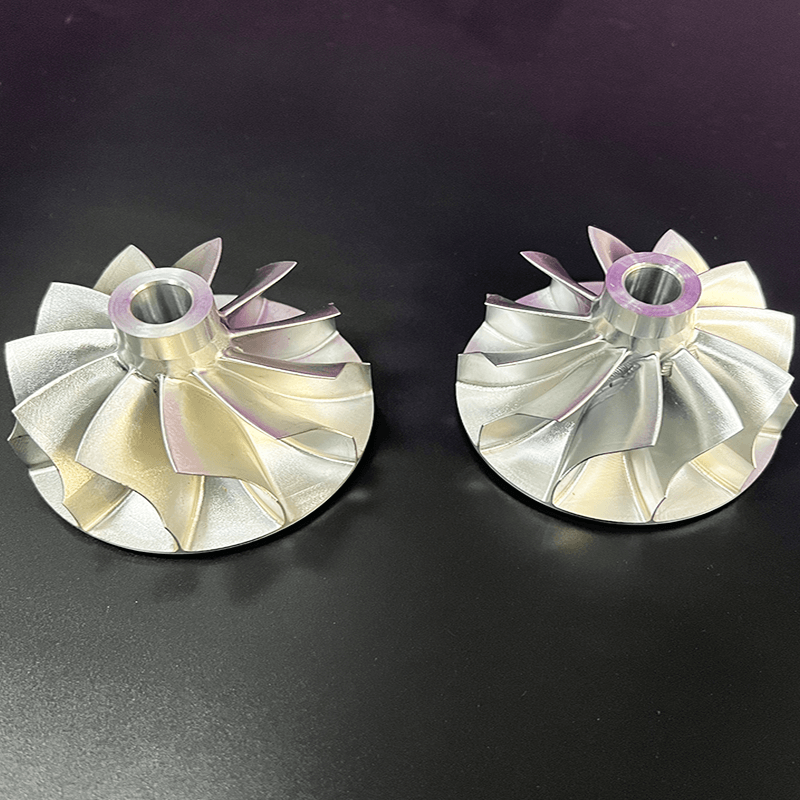

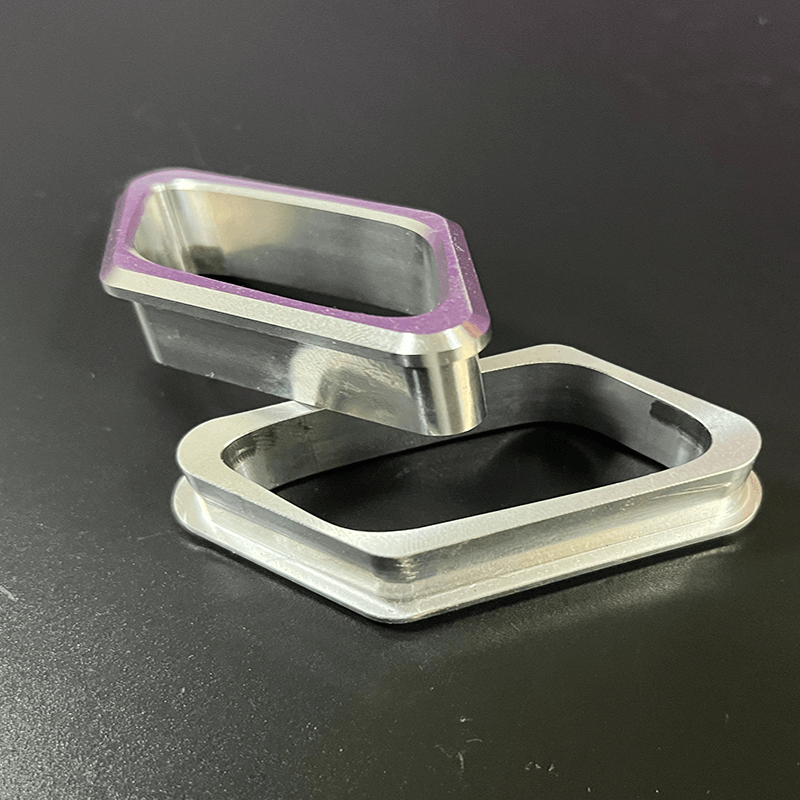

Our CNC milling process efficiently delivers custom prototypes and end-use production parts in as little as one day. Leveraging both 3-axis and 5-axis indexed milling technology, we manufacture components from over 30 engineering-grade plastics and metals. For high-volume production, we provide competitive pricing, first article inspection (FAI) reporting, material certifications, and finishing options like anodizing and chromate plating.

CNC mills are sophisticated automated cutting machines equipped with rotating spindle heads that precisely remove unwanted material. These machines come in various sizes and axis configurations, making them versatile for cutting hard metals as well as materials like plastic, aluminum, stainless steel, and titanium.

At Lsrmold, we ensure seamless execution of your CNC milling projects through our in-house machining capabilities and a comprehensive supplier network, allowing you to focus on bringing your product to market. For dependable CNC milling services, Lsrmold is your trusted partner.

Why Choose Lsrmold for CNC Machining Services?

State-of-the-Art Equipment and Materials

At Lsrmold, we leverage advanced 5-axis CNC machining centers to produce high-precision molds from a broad spectrum of materials, including aluminum, brass, nickel, and various grades of steel, including stainless steel. Our cutting-edge software ensures optimal performance and accuracy in every mold we create.

Demonstrated Expertise

Our reputation for excellence is built on a solid foundation of experience and proven results. We handle every stage of the CNC machining process—from initial product design and material selection to prototype development and final production. Our portfolio of successful projects is a testament to our capability and reliability.

Rigorous Material Testing and Quality Assurance

We prioritize rigorous testing of raw materials, subjecting them to comprehensive chemical and physical analysis using advanced scientific equipment. This meticulous approach to material quality control, coupled with Certificates of Compliance upon request, ensures that each mold meets the highest standards. In-process inspections further guarantee that every part is produced precisely to your design specifications.

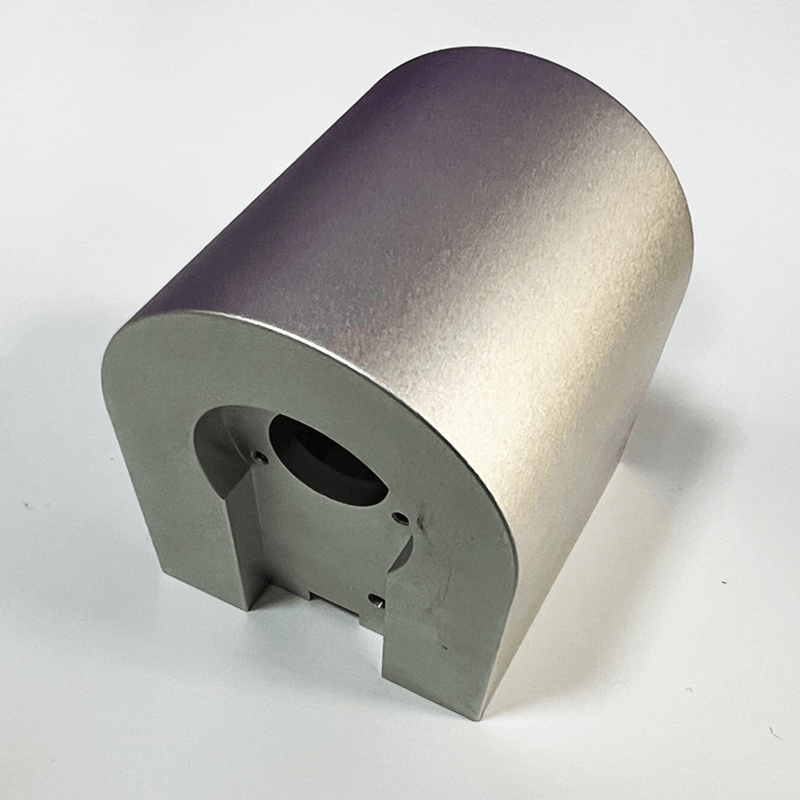

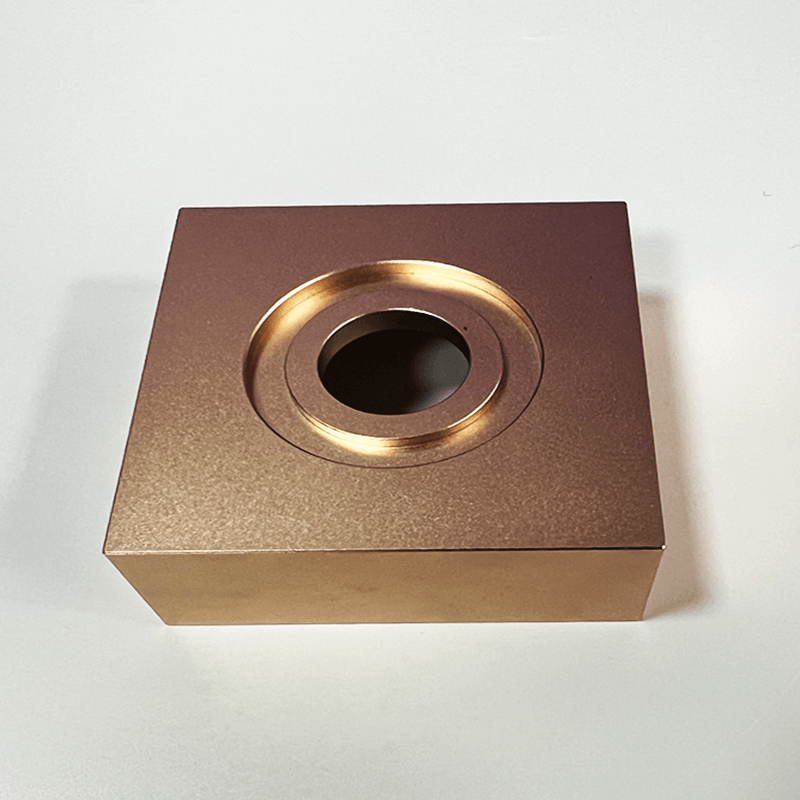

Extensive Finishing Capabilities

To ensure that every CNC machined mold meets your exact requirements, we offer a full suite of finishing services. From bead blasting and polishing to anodizing, plating, laser etching, and painting, we provide the finishing touches needed to enhance both the functionality and aesthetics of your mold.

Advantages of CNC Milling Services for Mold Developers

Our CNC milling services offer numerous advantages for mold development, making them ideal for both rapid prototyping and volume production. Here’s what you can expect:

- Quick removal of large amounts of metal and engineering-grade plastic resins.

- High accuracy and repeatability.

- Excellent for creating complex geometries.

- Versatility in applications.

- Suitable for a wide range of substrates.

- Scalable production volumes from one to 100,000 units.

- Low investment in tooling and preparation costs.

- Fast turnaround times.

- Full-strength parts ready for immediate use.

- Exceptional surface finishes.

- Easy customization.

Incorporating these benefits with mold production, our CNC milling services ensure high-quality and efficient manufacturing processes.

Custom CNC Machining Materials

| Aluminum | Bronze/Brass | Copper | Plastics | Steel / Titanium / Zinc |

| Aluminum 5052 | Brass C360 | EPT Copper C110 | ABS | Alloy Steel 4130, 4140 |

| Aluminum 7075 & 7075-T6 | Brass 260 | Copper 101 | Acetal [Delrin] | ASTM A36 |

| Aluminum 6063-T5 | C932 M07 Bearing Bronze | Acrylic | Stainless Steel 15-5, 17-4, 18-8, 303 | |

| Aluminum 7050-T7451 | G-10 Garolite | Stainless Steel 303, 304, 316/316L | ||

| Aluminum MIC-6 | Nylon 6/6 | Stainless Steel 416, 420 | ||

| Aluminum 6061-T6 | PEEK | Steel, Low Carbon | ||

| Aluminum 2024-T3 | Polycarbonate | Steel A36 | ||

| PTFE [Teflon] | Titanium Grade 2, Titanium 6Al-4V, Zinc Sheet Alloy 500 | |||

| Polypropylene | ||||

| Ultra-High Molecular Weight Polyethylene |

We offer a wide range of additional alloys and tempers upon request, sourced to meet your specific mould requirements. If your desired alloy or material is not listed on our platform, simply select "Other" and specify the material.

For custom CNC milled parts, including both metal and plastic options, we provide instant online quotes. If the material stock you need is not available, choose "Other" under the material drop-down menu on the quote page. Submit your request for an expert engineering review by specifying features, tolerances, inspection needs, and quantities required. Our services ensure that your mold production meets the highest standards of quality and precision.

CNC Milling Tolerances

At Lsrmold, we provide a comprehensive range of CNC machining tolerances tailored to your specific design needs, including GD&T callouts. Depending on your mold’s geometry and material selection, we can handle standard thread sizes, create custom threads, and achieve tolerances as precise as ±0.001”. For CNC milled metals, our standard tolerances adhere to ISO 2768-m, while for plastics, we follow ISO 2768-c.

| Description | General Tolerance or Standard |

| Maximum Part Size | Milled parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). |

| Distance Dimensions | For features of size (Length, width, height, diameter) and location (position, concentricity, symmetry) +/- 0.005”. |

| Orientation and Form Dimensions | 0-12″ +/- 0.005″, Angularity 1/2 degree. For 24″ and beyond please consult RJCmold’s Manufacturing Standards. |

| Precision Tolerances | RJCmold can manufacture and inspect to tight tolerances per your drawing specifications including GD&T callouts. |

| Minimum Feature Size | 0.020” (0.50 mm). This may vary depending on part geometry and chosen material. |

| Threads and Tapped Holes | RJCmold can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review. |

| Surface Finish | The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote. |

| Edge Condition | Sharp edges will be broken and deburred by default. Critical edges that must be left sharp should be noted and specified on a print. |

Surface Finishes for CNC Milling

Enhance the aesthetic and functional qualities of your custom CNC-milled molds with our premium surface finishing options. These finishes not only address visual imperfections but also add rigidity, protection, and increased durability to your molds.

Anodizing

Anodizing enhances corrosion resistance, increases wear resistance and hardness, and protects metal surfaces. Commonly applied to mechanical parts, aerospace components, and automotive parts.

Materials: Aluminum.

Bead Blasting

Bead blasting provides a smooth, matte finish suitable for visual applications. This process is often used as a preliminary step before additional surface treatments.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel.

Powder Coating

Powder coating offers a robust finish applied as a free-flowing, dry powder. Unlike traditional liquid paints, it is electrostatically applied and then cured with heat or UV light, providing a durable and consistent coating.

Materials: Aluminum, Stainless Steel, Steel.

Electroplating

Electroplating can serve functional, decorative, or corrosion-resistant purposes. This process is frequently utilized in industries like automotive, where chrome-plating is common for steel components.

Materials: Aluminum, Steel, Stainless Steel.

Polishing

Polishing achieves a high-gloss finish either through physical rubbing or chemical processes, resulting in a smooth surface with significant reflectivity, while reducing diffuse reflection in some materials.

Materials: Aluminum, Brass, Stainless Steel, Steel.

Brushing

Brushing involves using abrasive belts to create distinct surface textures, often for aesthetic purposes.

Materials: ABS, Aluminum, Brass, Stainless Steel, Steel.

With a diverse array of CNC finishing services available and our commitment to quality through rigorous inspection processes, you can be assured of receiving top-notch parts every time. Upon receiving your 3D CAD file, our experienced customer service engineers will evaluate your mold for manufacturability, ensuring it meets both your design specifications and budgetary constraints. Contact us today for a complimentary quote!