Description:

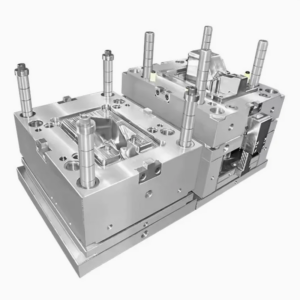

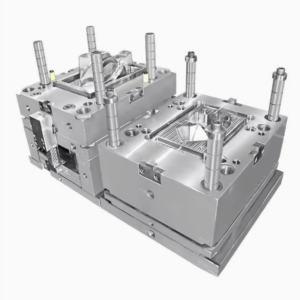

Plastic injection overmolding is a specialized technique used in the manufacturing of electronic devices, home appliances, and other household electronic products. This process involves molding one plastic material over another, creating a seamless integration of two materials to form a single, integrated part. Overmolding adds a soft-touch grip by overlaying a pliable, rubber-like thermoplastic elastomer onto a rigid plastic substrate. This innovative approach not only enhances the aesthetic appeal of products but also offers functional benefits, allowing for the creation of intricate and versatile designs. Plastic injection overmolding mold is widely valued for its ability to improve the ergonomics and durability of various components, providing both structural integrity and a comfortable user interface.

Features:

| Category | Details |

| Application | Automotive, Household Appliances, Furniture, Consumer Goods, Electronics, Hardware, Home Use |

| Runner | Cold Runner |

| Design Software | UG (Unigraphics) |

| Installation | Mobile |

| Certification | TS16949, CE, ISO |

| Standard | HASCO |

| Customization | Customized |

| Quality | High Quality |

| Price Term | FOB, CFR, CIF, DAT, DDP, EXW |

| Mold Life | 100,000 – 5,000,000 Shots |

| QC Machine | 3D Measurement, Profile Projector |

| Mold Standards | DME, HASCO, FVTABA, LKM, and Others |

| Tool Machine | CNC, CNC-Wirecut, EDM, Milling, Grinding |

| Export Country | Worldwide |

| Specification | According to Client’s Drawing or Sample |

| Origin | China |

| Production Capacity | 50 Sets / Month |

Packaging Details:

Packaging for plastic injection overmolding parts in the medical and pharmacy sectors is meticulously designed to ensure the safety and integrity of sensitive components. Custom-designed trays or blister packs made from durable materials like plastic or foam are commonly used. Each part is securely placed within its designated compartment to prevent damage during transit. Additional protective wrapping or cushioning materials may be included for extra security. The packaging is securely sealed to maintain sterility and prevent contamination, adhering to the stringent requirements of the medical and pharmacy industries. This careful packaging ensures that all parts arrive at their destination in perfect condition.

Key Surface Treatments for Plastic Injection Overmolding Molds:

1.Polishing: Creates a smooth, high-gloss finish to enhance the final product’s appearance.

2.Texturing: Adds specific patterns to the mold surface for improved grip and desired aesthetics.

3.Plating: Coats the mold with metals like chromium or nickel to increase durability and corrosion resistance.

4.Nitriding: Introduces nitrogen to harden the mold surface, enhancing wear resistance and mold longevity.

5.Laser Engraving: Etches detailed designs or markings directly onto the mold surface for precise customization.

Factory Show:

We operate a state-of-the-art production facility equipped with a diverse range of advanced machinery to ensure superior manufacturing quality. Our mold-making capabilities include cutting-edge CNC machines, Mirror EDM, EDM, and Slow-speed Wire Cut WC, alongside various auxiliary tools.

In our production lines, we utilize 15 rubber compression molding machines and 2 LSR injection molding machines to achieve precise results. Quality assurance is maintained through the use of 3D projectors, sealing testers, elasticity measurement tools, durometers, and a dedicated quality control team.

Our mechanical equipment inventory features an AutoDryer Line, automatic screen printing machines, 3D measuring instruments, high-speed automatic doming machines, die-cutting machines, and CNC machinery, among others, ensuring comprehensive support throughout the production process.