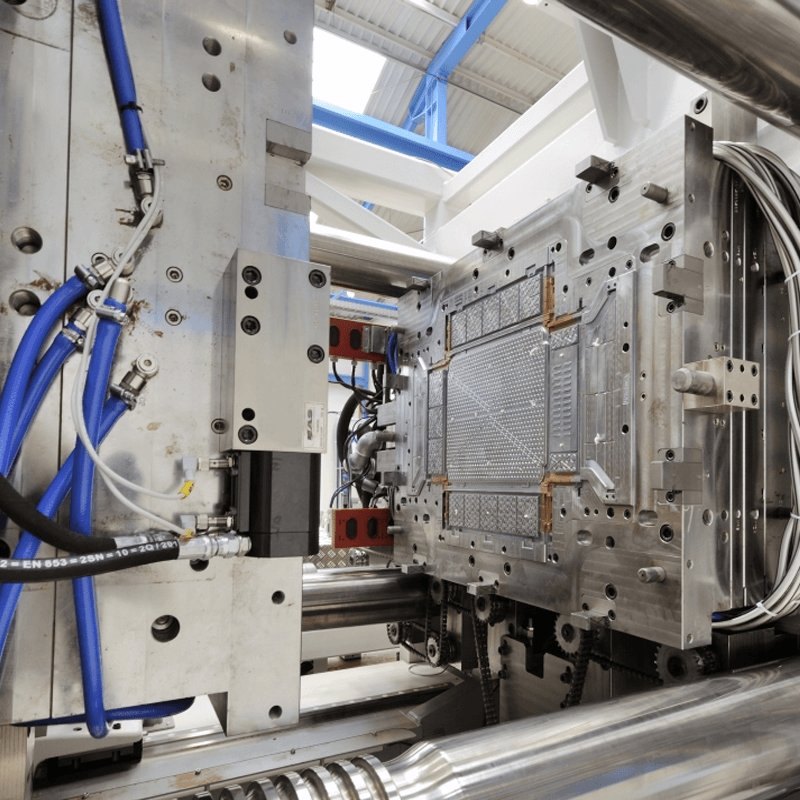

LSR and Plastic Molding & Tooling

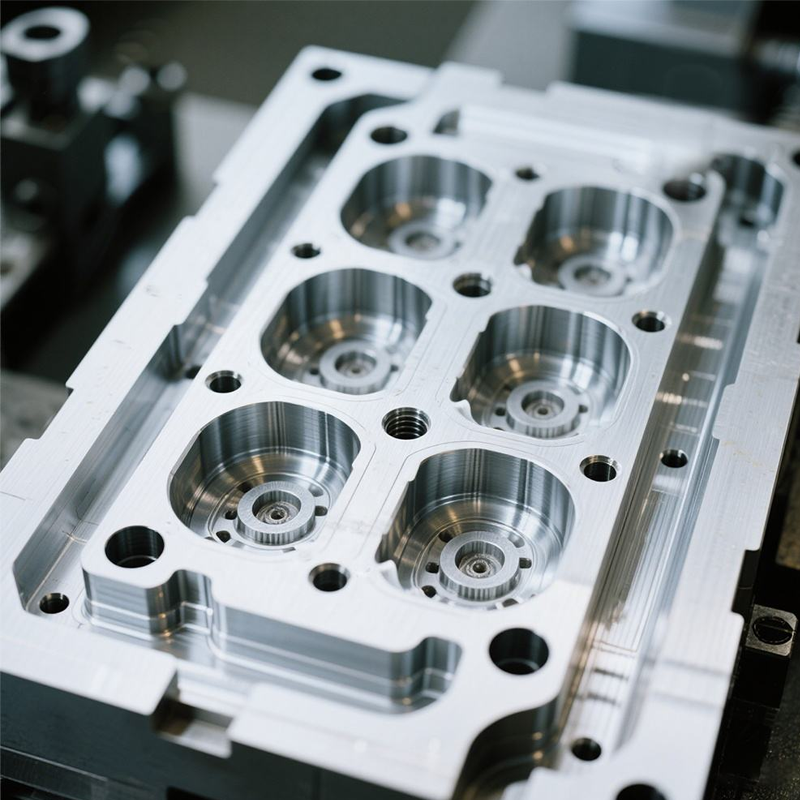

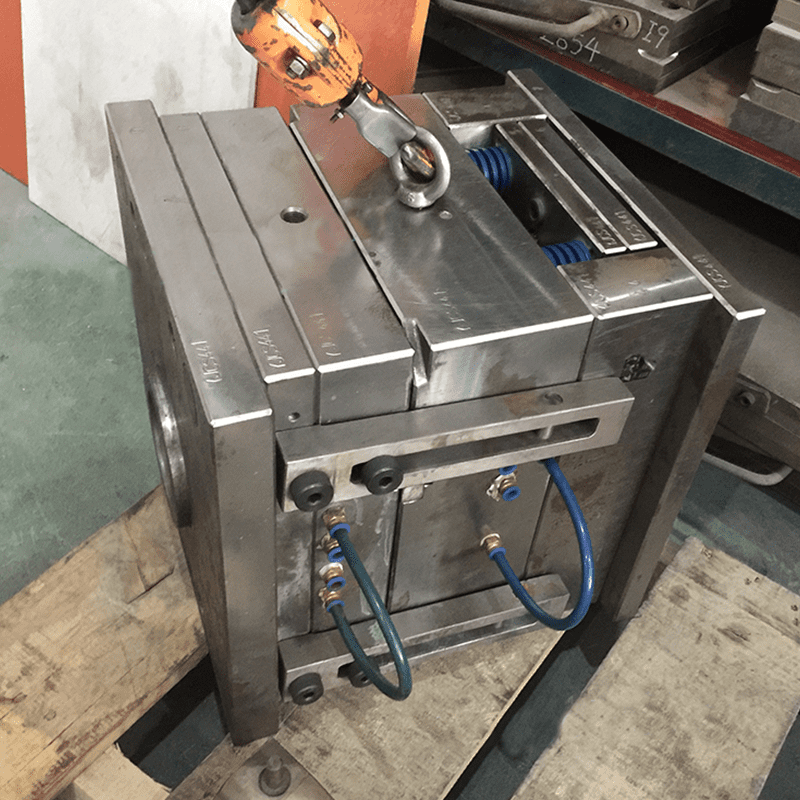

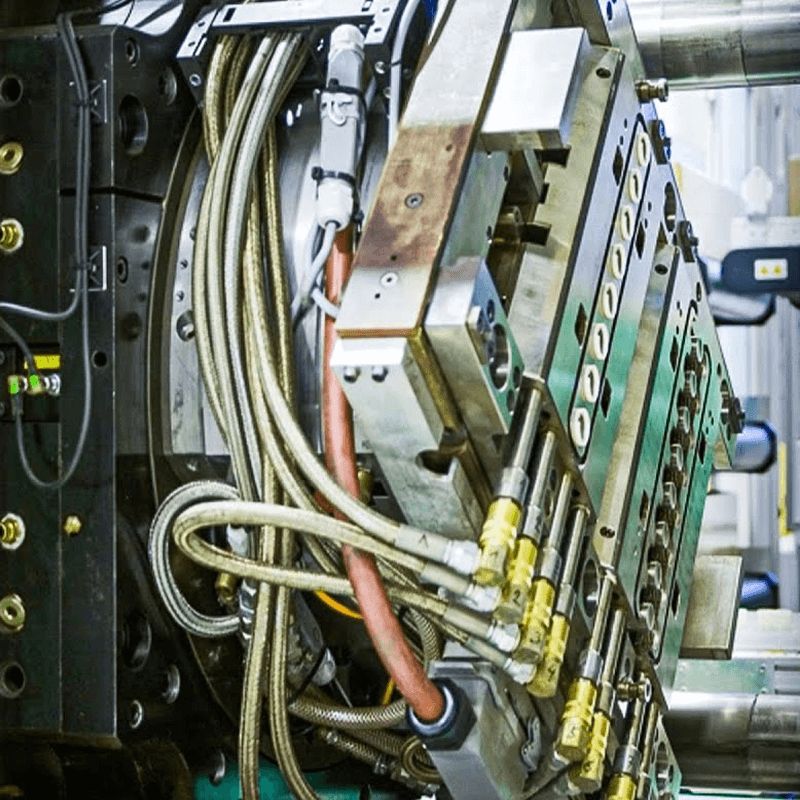

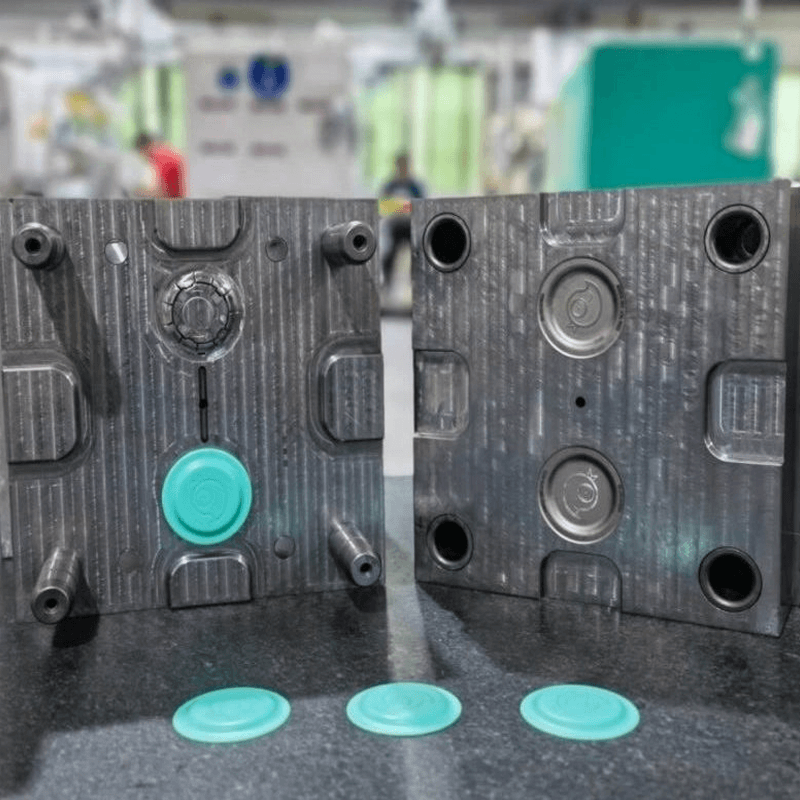

Experience premium, cost-effective custom plastic silicone parts and molds from our expert injection molding company. Every injection mold and production part is meticulously crafted in-house. Additionally, we offer custom machined parts, backed by our IATF 16949 and ISO 9001 certifications, ensuring the highest standards of quality and precision.

About LSR Mold

Lsr mold is an engineering design firm offering product development services across various industries, including medical devices, consumer electronics, new energy, kitchen bath and industrial equipment.

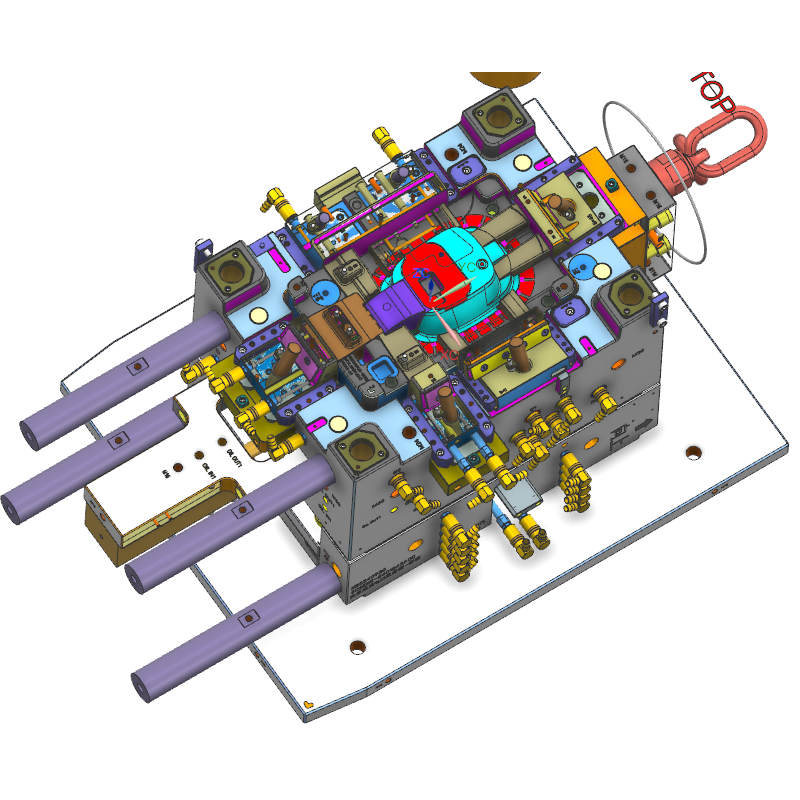

We provide services such as mold & tooling design, mechanical engineering, prototyping, injection molding and manufacturing support. Our collaborative approach to product development ensures that we work closely with clients to meet their specifications and prepare designs for manufacturing(DFM).

-

Premier Manufacturer of Custom Silicone and Plastic Molds

Our ISO 9001 and IATF 16949 certified facility excels in the production of high-quality custom silicone and plastic molds. As an industry leader, we are committed to delivering superior OEM services, addressing the unique challenges faced by entrepreneurs. Whether your product is new, patent-pending, or in the prototype stage, we offer tailored solutions to meet your specific needs.

-

Expertise Across Multiple Industries

Our extensive experience spans various industries, including medical devices, consumer electronics, automotive components, industrial custom parts, and kitchen and bathroom supplies. We customize our solutions to meet the distinct requirements of each sector.

-

Fast Quotation and Order Tracking

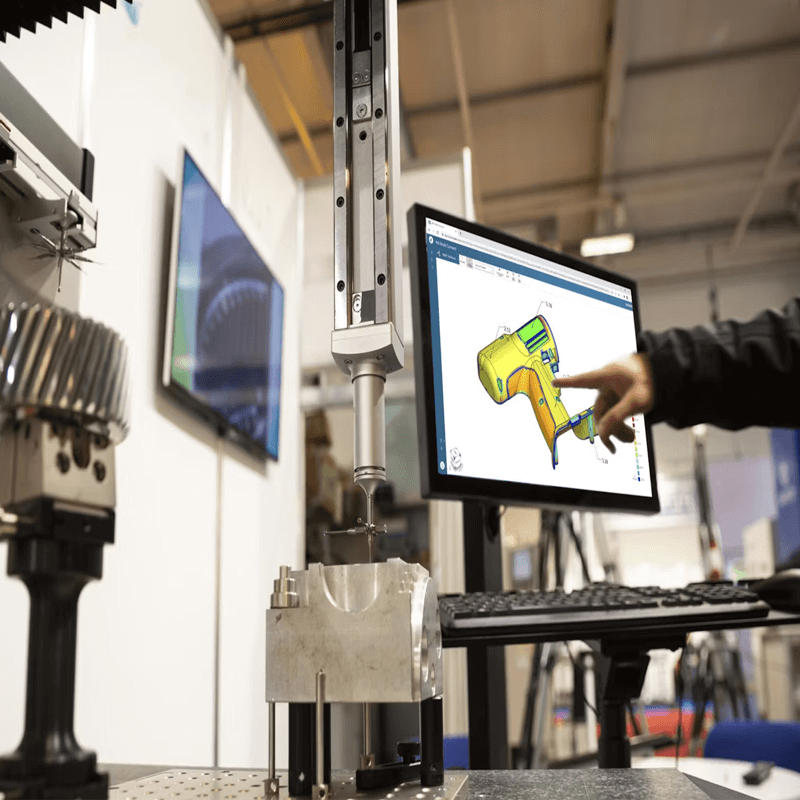

Our user-friendly quotation platform offers immediate DFM feedback, competitive pricing, and accurate lead times. Simply upload your CAD files for an instant quote. Our efficient order management and tracking system provides continuous updates throughout the production process, ensuring transparency and timely delivery.

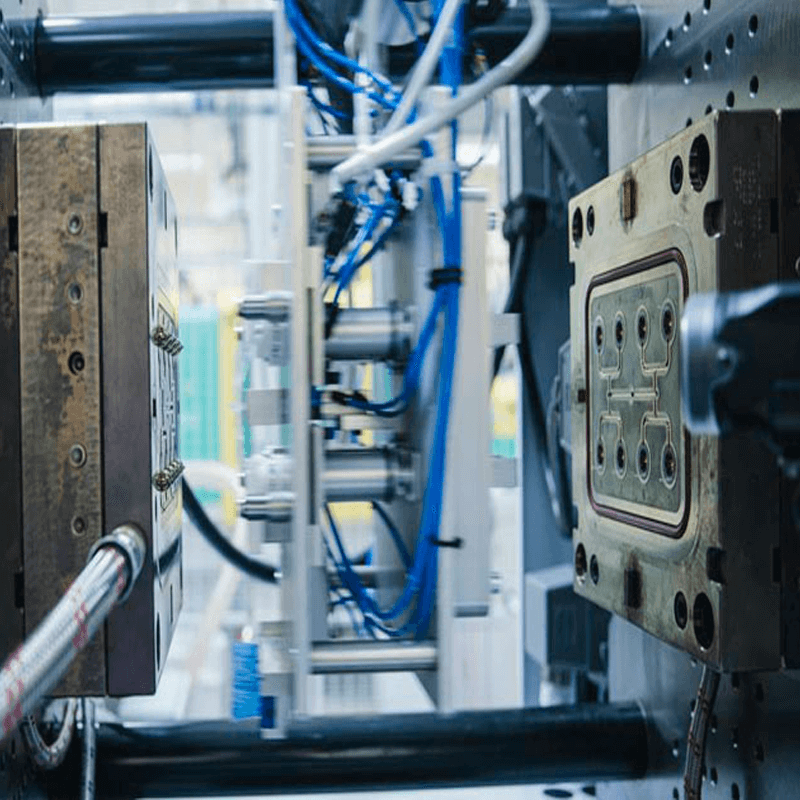

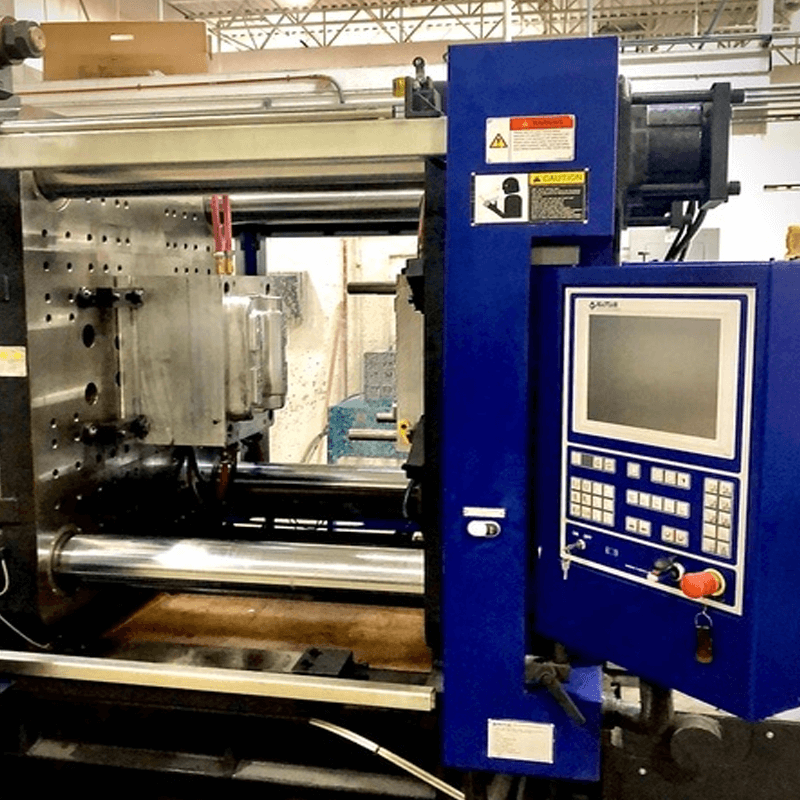

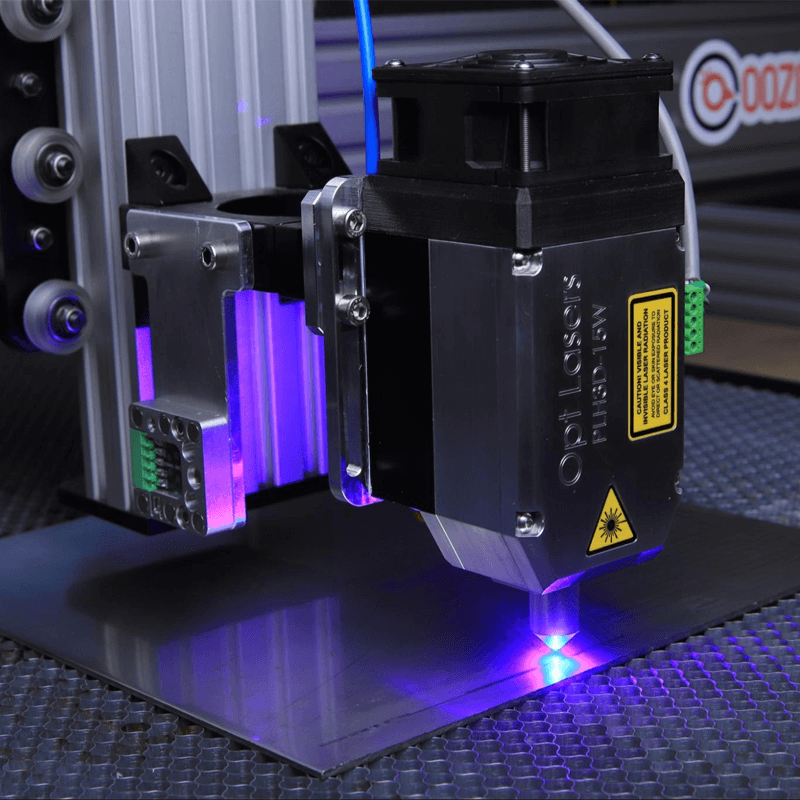

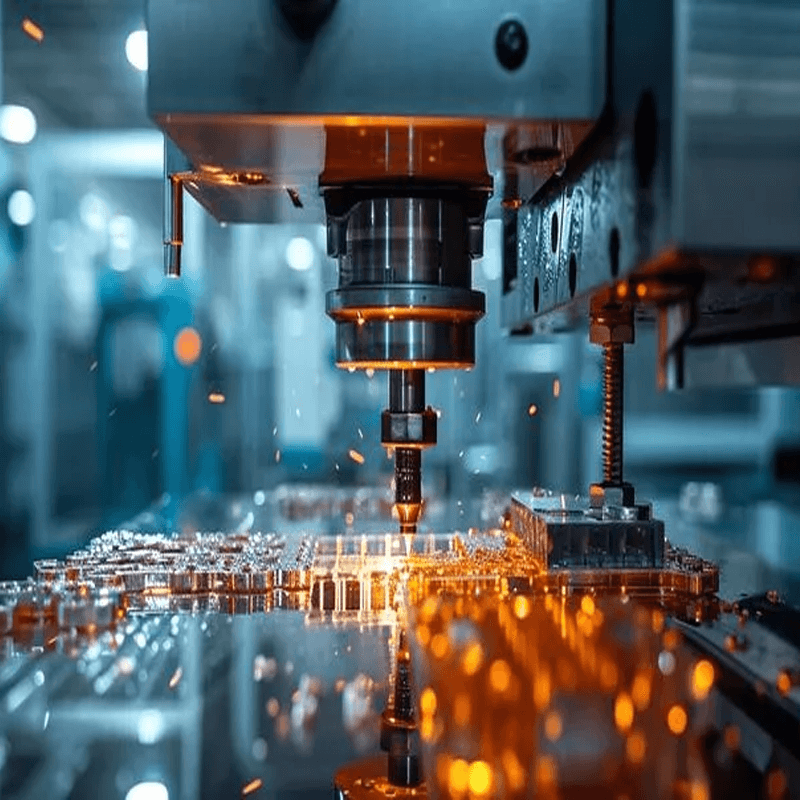

State-Of-The-Art Technology

One-Stop Service for Mold Development

Collaboration and Design

The process begins with close collaboration with the client, starting from a simple description or sketch.

Prototyping

Once the design is finalized and approved by the client, we proceed with the prototyping phase.

Production

After the prototype is approved, we move the product into mass production.

Sustainability

We maintain and support the user interface throughout the product lifecycle, ensuring that the originally designed products continue to receive support.

Step1: Send 3D Drawing or Samples

Lsrmold accepts these file types:

•ProE (prt)

•IGES (igs)

•STEP (stp)

•Parasolid (x_t or x_b)

Your can send us your samples, too.

Step2: Receive DFM and Quotation

Once receiving your Drawing or samples. We’ll send you the design for manufacturability (DFM) and the quotation.

Step3: Start to Manufacturing

After your approval of DFM and Confirm the order , we will begin to manufacturing:

•CNC Machining

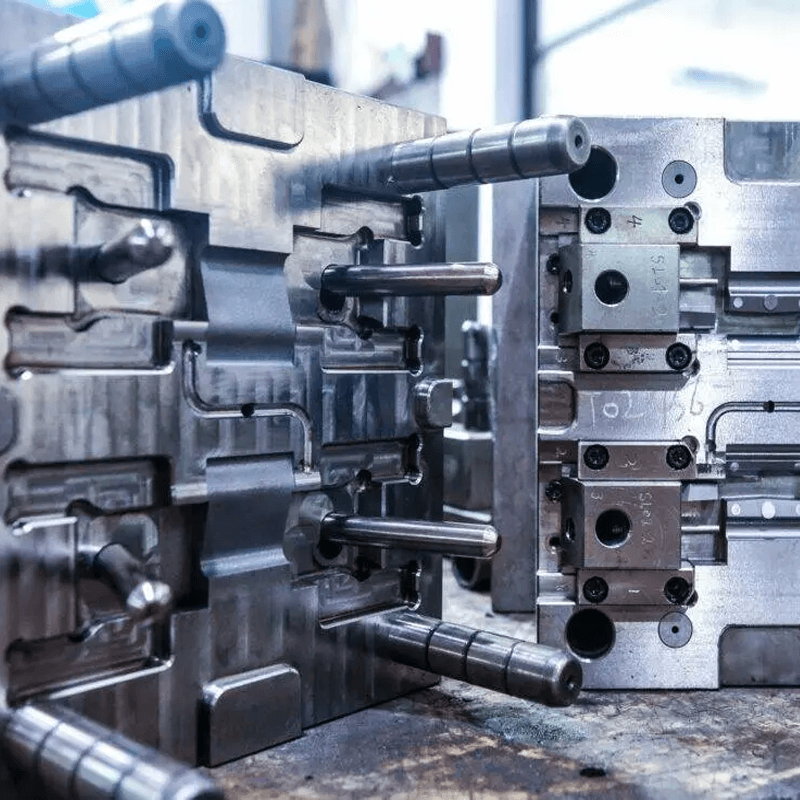

•Mold Making

•Molding process

•Rapid Prototyping

Step4: T0 & P0 samples approval

We will send the samples for your checking and confirmation,

•FAI

•TDS/MSDS

•Rohs

Step5: Packing and Transporting Goods

After you check and confirm the T0 & P0 samples , we will ship the molds or product by:

FedEx, UPS, DHL, TNT, by the ocean, or you can ask your own freight forwarder to pick up the goods.

CONTACT US: sales@lsrmold.com

Your Trusted Partner for Plastic Injection Molded Products

Lsrmold produces high volume, quality-consistent custom plastic injection molded products. We are aware of today's time compressed market requirements and ever changing supply demands. We remain adaptable, meeting the needs of our customers.

Precision Custom Compression Molding Tooling Mould for Consumer Electronics Parts Manufacturer

Description: We design and manufacture precision custom compression molding tooling for durable consumer electronics parts. Our molds produce high-quality silicone rubber components like seals, gaskets, and grips with exceptional consistency. […]

Read MoreOEM Injection Mold Tooling for Consumer Plastic Shell Cover Suppliers

Description: We provide professional OEM injection mold tooling for high-volume production of consumer plastic shell covers. Our molds ensure precise replication of complex designs, excellent surface finishes, and consistent quality […]

Read MoreCustom High Standard Overmolding Mold Tooling for Rice Cooker Panels Manufacturer

Overview This Custom High Standard Overmolding Mold Tooling is engineered for producing integrated rice cooker control panels with soft-touch keypads. It precisely bonds rigid substrates (PC/ABS) to TPE/silicone, ensuring waterproof […]

Read MoreCustomized Injection Mold Tooling for Plastic Baby Bath Tub Manufacturer

Overview Our customized injection mold tooling for plastic baby bath tubs is engineered for safety, precision, and high-volume production. Utilizing food-grade materials like PP and TPE, our molds guarantee smooth, […]

Read MoreCustom High Precision Silicone Compression Mold Tooling for Cylinder Bellows

Overview Our custom tooling molds precision compression molds for durable silicone cylinder bellows. Engineered from premium steels with CNC and EDM machining, they ensure exacting concentricity and wall thickness. We […]

Read MoreCustom SKD61/S136/H13 Tooling Molds for Electronics Home Appliances Manufacturer

Overview: Our Custom SKD61/S136/H13 Tooling Molds for Electronics & Home Appliances are engineered for high-volume precision injection molding of intricate plastic components. Utilizing premium mold steels like SKD61 for heat […]

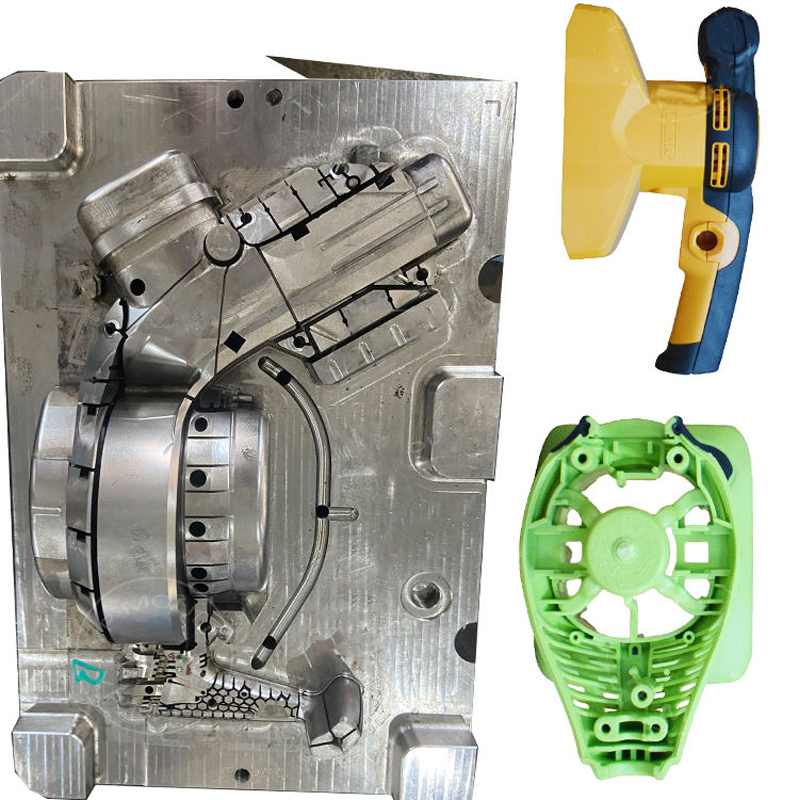

Read MoreCustom Plastic Injection Tooling Mold for Overmolding Electric Tools Suppliers

Overview Our Custom Plastic Injection Tooling for Overmolding Electric Tools is engineered to produce durable, ergonomic components like handles, grips, and housings. Utilizing advanced CNC and EDM machining, our molds […]

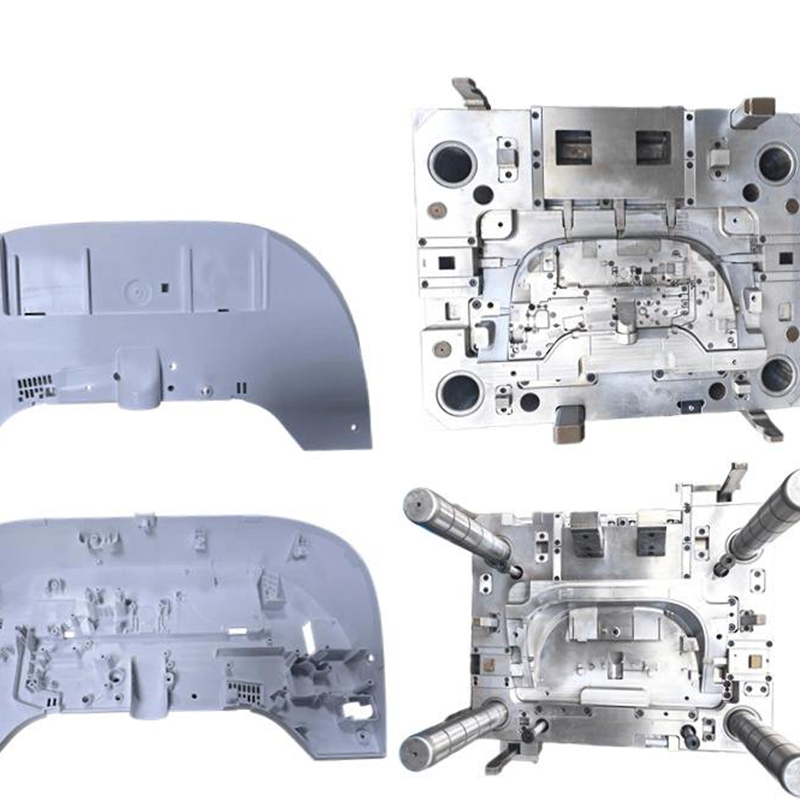

Read MoreCustom Precision Plastic Bathroom Cover Injection Mold Tooling for Sanitary Ware Household Factory

Overview The Custom Precision Plastic Injection Mold Tooling for Bathroom Covers (Sanitary Ware & Household) is engineered to produce high-quality, cosmetically perfect plastic covers and trim components for toilets, bidets, […]

Read MoreCustomized High Precision Injection Mold Tooling for Silicone & Plastic Festival Promotion Gift Parts Manufacturer

Overview Our Customized High-Precision Injection Mold Tooling for Silicone & Plastic Festival Promotion Gift Parts is engineered to deliver eye-catching, durable, and cost-effective promotional items for seasonal retail and brand […]

Read MoreInjection Molding Leader For Nearly Two Decades

Lsrmold specializes in manufacturing silicone and plastic injection tooling. We are renowned for our expertise in producing tight-tolerance optical lighting tools and thermoset molds. Additionally, we handle complex CNC machining projects and maintain an extensive inventory of state-of-the-art equipment.